Software Simplifies Turn-Mill Operations

An international player in the highly competitive aeronautics, automotive, defense and optical industries makes the most of software for multitasking program verification and optimization.

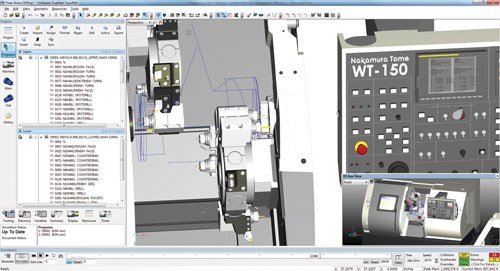

This video shows the synchronization of the left and right spindles on the Nakamura-Tome WT-150 II from Methods Machine Tools. A spindle with a 0.040 x 0.040 x 3/8 link is between two spindles The spindle goes forward up to 5,000 rpm and reverse back to stop. The 0.040 x 0.040 link is still intact, demonstrating the accuracy of real spindle sync.

Today more than ever, it is crucial that North American manufacturers constantly improve on their technology and processes. Multitasking machine tools are becoming more widely used to help manufacturers compete globally. These machines introduce new challenges for ensuring that a safe and optimum NC program is obtained the first time to reduce machine downtime and program prove-out.

APN Inc., while a 42-year-old company, is an ultra-modern machine shop located in Quebec City, Quebec, Canada. Making extensive use of multitasking machine tools, the company produces parts for the aeronautic, optical, ammunition and automotive industries in a volume close to 50,000 per year.

Featured Content

Machines and Parts Defined

APN uses three Nakamura-Tome WT-150 multitasking machines to produce most of its high precision turned parts in batch sizes ranging from 20 parts to more than 1,000. Multitasking machines have been engineered to produce highly complex turned parts (most with complex milling features) with high accuracy and quality. Precision and high quality is an essential component of APN’s deliverables to its customers. The WT-150 consists of two spindles and two turrets that can operate independently or in a synchronized fashion. All six sides of a part can be machined and finished with a single setup, allowing production batches to be run as part of a “lights out” manufacturing environment. Parallel operation allows multiple functions to be performed simultaneously on the parts, saving significant time.

In traditional multitasking, careful optimization by experienced programmers and operators is required to effectively take advantage of the machine’s capabilities. This means long setup times on the machine and extensive part prove-outs. During this time, no parts are produced and the machine is not “making money.” There is always a trade-off between the amount of time spent on optimization (therefore increasing machine downtime during this process) and the time that the optimization saves per part.

Previous Turn-Mill Applications

In producing a certain automotive component, APN used its previous CAM software to easily recognize and program features coming from the solid model of the part. After programming was complete, though, operators would bring the non-optimized programs to the machine. From there, a long prove-out process would occur.

The operator would first check for any over-travels or potential collisions, then slowly look at which operations could be run simultaneously, manually inserting wait marks to synchronize these operations. APN also struggled with the inability to program part transfers between the main and subspindle, as well as the cutoff operation from the barstock. Depending on the number of tools and operations, this process would be lengthy, tying up the machine.

Improving Results

With large volumes of parts to produce, APN needed a solution to get the most out of its machines, rather than having them tied up doing part prove-outs. The company now uses CAMplete Solutions’ TurnMill. This integrated software solution intelligently post processes, simulates and optimizes programs exclusively for Nakamura-Tome machines. NC programmers at APN use the code generated by the CAM software, and then import it into CAMplete TurnMill to accurately simulate and optimize the programs before anything is run on the machine. The software allows APN to visualize and verify the entire setup (spindles, turrets, tools, holders) off line to avoid downtime on the machine. The biggest advantage for APN is not only the ability to optimize all the machining sequences between the main and subspindle and balance load between upper and lower turrets, but also the ability to move operations between channels and intelligently insert the proper synchronization codes where required. APN also now can adjust the part transfer and cutoff parameters.

The same part setup that used to take APN hours is now done within less than 30 minutes, off-line, while the machine is running, still producing parts from the previous job. This is a significant gain for APN and the programmers. They can now focus on optimizing the programs as much as possible without having to worry about a collision, over-travel or a tool that is set up incorrectly.

CAMplete TurnMill integrates all the aspects of the Nakamura-Tome machines. As such, APN also uses the software to get accurate time estimates and confirm the sales target established. Having the ability to accurately validate a cycle time, even before the machine is turned on, gives the company the strategic advantage its needs to take its business to the next level, beating its competitors while reducing costs.

RELATED CONTENT

-

From Setup to Final Pass: CNC Tool Management

With today’s high-powered and graphic-intense CNC, operators have everything under control, all on one screen.

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

-

Why Using Pirated Software is Riskier Than Ever

Machine shops and manufacturers that use pirated software risk losing much more – both directly and indirectly.