Strategy Change Leads to Performance Boost

The application of a Horn Type 636 slot milling cutter has set new standards of accuracy, tool life, process reliability and costs for milling recesses on planetary gears at Sitec Aerospace in Bad Tölz, Bavaria, Germany.

The application of a Horn Type 636 slot milling cutter has set new standards of accuracy, tool life, process reliability and costs for milling recesses on planetary gears at Sitec Aerospace in Bad Tölz, Bavaria, Germany. Milling cycle time has been reduced by half (to about 5 minutes, 30 seconds per component), and part-to-part dimensional consistency, as-machined surface finish and tool life have significantly improved.

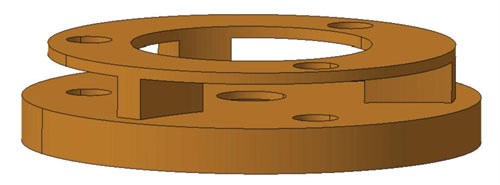

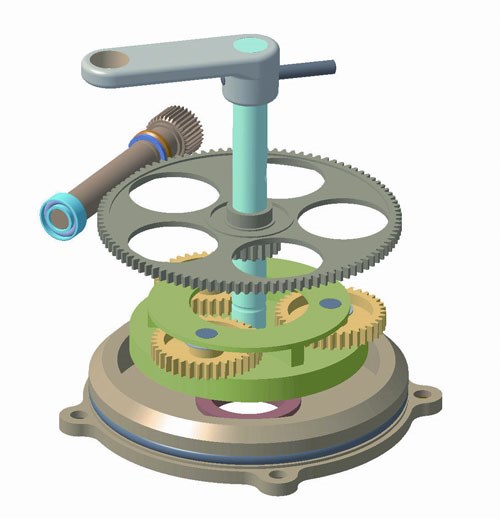

Helmut Bachmair, production manager, is motivated to maintain the strict safety and quality requirements of aerospace while improving process economics. A recent project focused on finding ways to optimize the milling of three recesses offset by 120 degrees for the planetary gears on a planetary gear carrier.

Featured Content

The 130-employee Sitec Aerospace, a wholly-owned subsidiary of Singapore Aerospace Manufacturing, produces valves, rotor blade shock absorbers, actuators and hydraulic components for the aviation industry. In addition, pneumatic manipulators are manufactured for broader industrial use. In the aviation area, approximately 9,500 actuators are produced annually. However, valves for different requirements and media are part of the core competence of the company.

The previous milling method the company used was an HSS side milling cutter for the rough milling, followed by a solid carbide saw blade for finish milling. Because of the high helix angle, chips repeatedly lodged between the small teeth. After five or six workpieces, the milling cycle results were scattered throughout the permissible tolerance range. This caused significant problems for subsequent machining operations. The milling portion of the 11 minutes needed for manufacturing the planetary gear carrier also needed to be reduced.

To fix the problem, Mr. Bachmair‘s team initiated a trial using an existing slot mill, and the results were impressive. However, after using a standard Horn Type 636 tool with adapted cutting geometry instead of the existing tool, the decision was made to continue using the Type 636 tool.

Slots in the range of 1.5- to 3-mm width and as much as a 12-mm depth can be milled with the standard cutters. The inserts have six cutting edges and can be used for a cutting edge diameter of 35.7 mm from a bore diameter of 36 mm. They used a vibration damping solid carbide shank M332 and located the work by using a single bolt onto the asymmetric insert seat, guaranteeing high precision and secure location. Various holders with cylindrical shank and internal coolant supply in different lengths enable adaptation for various machining operations. The internal coolant supply also ensures reliable working in deep bores.

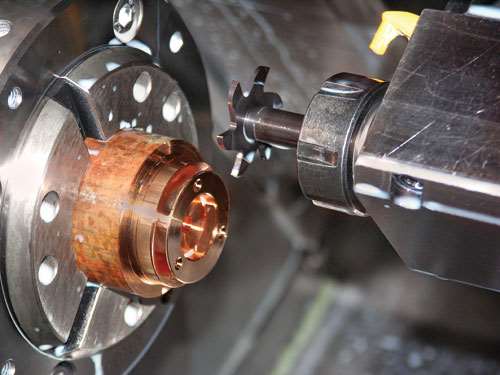

According to the requirements specification, the planetary gear carriers had to be completely machined, with an average batch size of 500 pieces, on a Gildemeister MF Twin 65, two-spindle production turning center and needed to comply with several tolerances in the lower hundredths range. The particular requirements for the Horn tooling were determined from these specifications; interfaces of the powered tools, mainly with respect to concentricity, must not affect the milling cutter.

The contour milling operation using rough milling and finish milling is also carried over to the new circular groove milling strategy. Both operations use the insert 636 and the shank M332. Both slot millers are used at a speed n = 1,340 rpm for the rough milling and finish milling. For roughing, a feed rate v = 0.15 mm per revolution with a cutting depth of approximately 8 mm is used. For finishing, the feed rate “v” increases to 0.2 mm per revolution, and a cutting depth of approximately 0.4 mm is selected. In addition to Type 636, Horn combination milling cutters from the DM series and inserts from the Supermini series are used for subsequent deburring of the various edges and bores on the planetary gear carrier.

Mr. Bachmair is extremely satisfied with the performance of the circular mill 636. “Once set up, no corrections are required, and our expectations, with respect to chip flow and tolerances, are completely fulfilled. The running time reduction from the original 11 minutes to almost half the time is also impressive.“ Also, because the selected milling cutter is a standard tool, not a special tool, costs are lower and delivery times are shorter.

Because of the outstanding milling results—the reliable work during the finishing and the reduction of reworking—Mr. Bachmair also wants to use Horn standard and special tools for other machining tasks. “There are enough possibilities,“ he says. “If we achieve similar time and cost benefits for other applications as for the planetary gear carriers, we will have come one step closer to our major objective of complete production optimization.“

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

.png;maxWidth=970;quality=90)