Swiss Shop Shows Its Value

Open communication, preplanning and quality control go a long way in maximizing the productivity of this company’s Swiss machines.

Every shop has its own way of communicating its strengths to customers on a regular basis to maintain current work and gain new business. While a number of factors can come into play, most often the big selling point is some combination of precision production capabilities, delivery time, customer service and price. If a shop can be competitive in all of these considerations, it has a good chance of landing the work it needs to succeed.

For Swiss-Tech, LLC (Delavan, Wisconsin), a manufacturer of high-precision turned products for the medical and aerospace industries, though, proving the company’s value was far more complex. It was facing the same challenges as others in generating and maintaining business, but it also was trying to attract the right buyer for the company.

Featured Content

On The Market

The company was founded in 1965, starting out with four employees and six Tornos cam machines in a 4,000-square-foot facility. Through the years, Swiss-Tech has grown considerably and has faced the challenges of a company sale a few times before. But each time the business has changed hands, it has experienced still bigger growth, and that was the goal for the upcoming transition.

While co-owners Ken Bliss and Vince Martin were considering retirement, they wanted to do what was best for the company and its employees in a sale of the business. They made a call to John Jones, who had worked with the company for 10 years in the ‘80s and early ‘90s. They felt his experience and knowledge of the industry could help build the company and prepare it for sale.

Cleary Gull, a group of investment bankers out of Milwaukee who help sell businesses, was hired to find a good buyer for the company. The firm brought in 11 groups who had interest in the purchase, and each was presented with a thorough rundown of what the company had to offer. After close scrutiny and consideration, Mike Adams and Todd McCuaig, of Cornerstone Industrial Group (Chagrin Falls, Ohio) were told they were management’s top choice. They stepped up to the plate and made the offer that would become the basis for the sale. With Cornerstone on board, Mr. Jones and a few others teamed up as partners in the purchase, and now, with the right management and business strategies in place, the company is poised to exceed all previous sales figures.

Why It’s Worth It

According to Mr. Jones, who, with the sale of Swiss-Tech, was appointed president, much of the company’s success lies in its commitment to customer communications. “At every level of the company,” he explains, “from sales to expediting to shipping to quality to engineering, you’ll find everyone fully interfaced with our customers. For example, our engineering department does a fantastic job of preplanning through brainstorming sessions and raising questions with the customer. It’s all about determining customer expectations and meeting them in the timeframe that the customer allows.”

Typically when a job comes in, engineering reviews the customer requirements and then breaks the print down into process drawings. A separate AutoCAD department redraws the customer print, allowing for plating, tolerances and heat treat growth. Then SPC is assigned to the dimensions of the print—sometimes driven by the customer and sometimes identified by engineering as an area of particular vulnerability.

Quality is also a major consideration for Swiss-Tech. It has more than 7,000 active part numbers in-house and more than 200 customers. Surface finish is critical for a large percentage of the parts produced, and many require individual, “no part-on-part” packaging. Given the strict requirements for finishes, the company has invested in a number of measurement and inspection systems throughout the shop. It is now adding Oasis non-contact video profile measurement and inspection systems that allow users to measure multiple dimensions on a part simultaneously and instantly.

Many of the company’s customers accept shipments straight to their stock, with no incoming inspections. They rely strictly on the data that Swiss-Tech supplies. “People sometimes forget that even when you ship a 10,000-piece shipment to a customer, every one of those parts is going to get used,” Mr. Jones points out. “If there’s a bad one in that batch, you can bet you’re going to hear about it. It’s not like the old days when the customer would accept a certain percentage of fallout. If we find that a certain part is generating too much fallout, we’ll take corrective action, and everyone will get involved in it and determine the cause. Customers can be very demanding these days; if you embrace that, it makes you so much better. After all, with the added inspection, time involved and replacing the part, it costs more to run a bad part than a good one.”

Quality Production

Near the back of the shop is a lineup of 70 cam-driven Tornos Swiss automatics of varying capacities. Mr. Jones is quick to point out that these machines are entirely capable of meeting the company’s high quality standards. He explains that these are precision machines with micrometer adjustments on every tool. To ensure the desired results, Swiss-Tech designs and cuts all of the cams in-house, designs and grinds all of the tooling for the cam machines and does its own maintenance on the machines.

“We hold 2 tenths tolerance with these machines just like we do on our CNCs,” says Mr. Jones. “The difference of whether a job goes on the automatics or on the CNCs has to do with lot size and complexity. We can do pretty complex parts with the cam machines, but they tend to be on the smaller end. When we get to the bigger, more complex parts, they’re more likely to end up on the CNCs. So the CNCs take our lower volume, more complex work, and the cams take the higher volume, less complex work.”

Regardless of the complexity, volume or machine it’s produced on, the goal is always a quality finished part. With the types of customers the company has, many parts (which can be as small as 20-thousandths diameter) require deburring under a microscope.

Intended For Untended

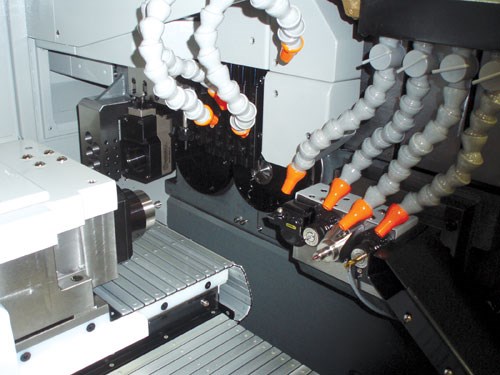

Much of the recent success of the company is attributed to the capabilities of its latest CNC machine acquisitions. There are about 100 Swiss machines of various makes, models and diameters on the shop floor, but the last 13 (including four in the last 2 months) have been Hanwha ML and SL series Swiss turning centers. Since bringing in the first Hanwha in 2004, the company has gone from zero lights-out operations to about 3 million untended parts a year.

By taking the time to engineer the parts up-front and understand the tool life and capabilities of the machine running the part, Swiss-Tech has made great strides in increasing productivity. “It starts with a rigid machine,” Mr. Jones says. “We have some Swiss lathes that are not capable of holding tolerances in lights-out conditions. The Hanwhas work well even with the 316 stainless and titanium. Those machines are what really kicked it off for us. Then we’ve been able to transfer some of that technology to our cam machines to be able to do lights out on those as well. We purchased magazine loaders for them, and through the use of SPC, we’ve identified our tool life so we understand how many parts we can get out of the tools.”

With a large casting underneath, these new machines bring the strength and rigidity all the way to the floor. Mr. Jones feels that it’s the rigidity of that mass that translates into the ability to hold tight tolerances, better tool life, better finishes and lights-out production capabilities.

Lights-out production has also contributed to other positive influences on the bottom line. The number of employees has been reduced. Shop personnel work 4, 10-hour days, with two shifts running. Each weekday, then, has a 3-hour span of lights-out, and longer-run parts are scheduled for weekends. The in-house scrap rate has also been improved. Mr. Jones says, “We get almost no fallout from our lights-out operations. It only makes us better all around because untended operations force us to pay much more attention to the process up front, making sure the engineering is proper. There’s no human safety net.”

Mr. Jones says that the company has so much confidence in the Hanwha machines that they are even buying older models that have been abused and rebuilding them to dedicate to a specific part. Currently, a 316 stainless medical part is running on an ML20H with a Fanuc 18iT control and 3/4-inch-diameter capacity. The cost of a brand new machine couldn’t be justified for this part, but he jumped at the chance to get a machine for less than $50,000 and run the part year-round, burr-free, untended.

Swiss-Tech chose the Hanwha particularly for its lights-out capabilities. “For us it’s the perfect lights-out machine,” Mr. Jones says. “It has high rigidity and practically no thermal growth. It has given us the confidence that with the right process in place, we can run untended without issue.”

It is that kind of confidence in the capabilities of both the company’s equipment and its personnel that keeps customers coming back, year after year. These are qualities that would make any buyer happy.

RELATED CONTENT

-

Dressing Technique for Truing Up Diamond Grinding Wheels

This tapered diamond grinding wheel dressing technique, which takes place inside the machine, is used in production of high-precision profile inserts.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.

-

Diamond Lapping and Lapping Plate Control

The word “diamond” brings the word “expensive” to mind. But when it comes to lapping with diamond superabrasives, start thinking “low”—as in lower slurry consumption, lower slurry cost per hour, lower sludge generation, lower cycle time, lower reject rates and fewer process steps.