The Advantages of Direct-Drive Technology for Manufacturing

Appears in Print as: 'The Advantages of Direct-Drive Technology for Manufacturing'

Direct-drive technology, the force of a motor being directly applied to a mechanism without any intermediate drivetrain such as a gearbox or toothed belt, has been around for more than 40 years, but some machine builders still may not fully appreciate its benefits.

Direct-drive technology has been around for more than 40 years, but many machine builders still do not fully understand its benefits. Even those who are familiar with the technology may not have a desire to adopt it, considering it as too high-end when compared with, for example, a gearbox drive solution that has been sufficient for many years. But in the same way smart phones and the Internet have evolved from a luxury to a necessity despite lower-end technology still existing, eventually the benefits of more advanced technology become too difficult to ignore.

Featured Content

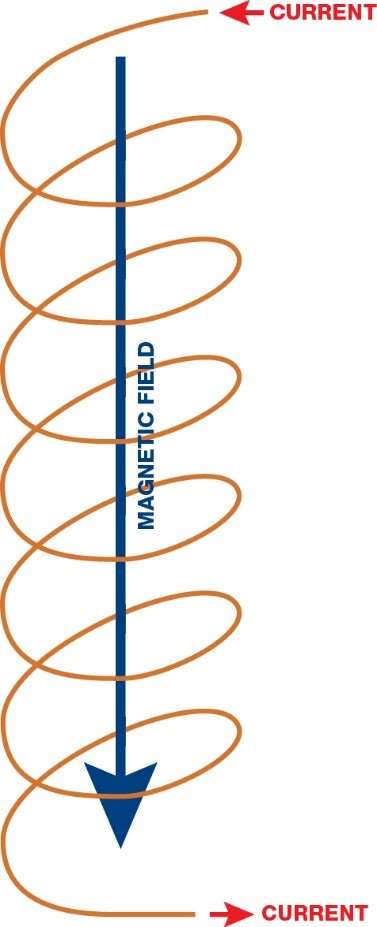

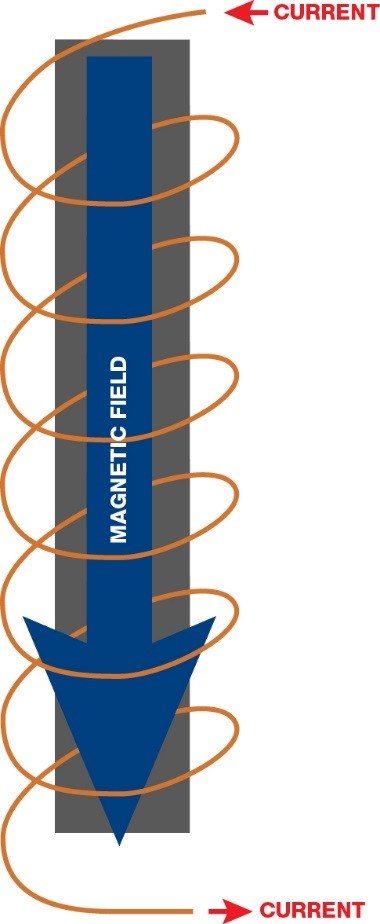

In today’s highly competitive world, the better people understand the advantages and benefits of direct-drive technology, the more they will have an advantage in machine building, giving them an edge over their competition. To understand these benefits, we start with the basic concept of direct drive whereby the force of a motor is directly applied to a mechanism without any intermediate drivetrain such as a gearbox or toothed belt. The core working principles of direct-drive motor technology are, in essence, based on the right-hand rule of electromagnetism, whereby a current moving through a wound coil in a known direction creates a magnetic field. Changing the direction of current changes polarity, and changing the amount of current changes the magnetic force. Putting a highly conductive material within the coil, such as iron, exponentially increases the magnetic force.

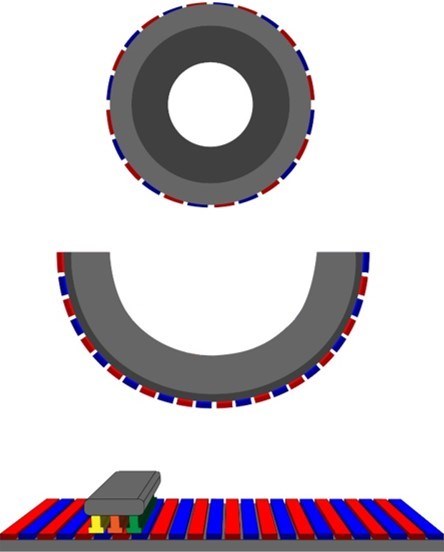

One more factor is to have some magnetic material with which this field can interact. In this case, it is a row of permanent magnets. Depending on the coil’s location relative to the magnet, the current can be adjusted in terms of its strength and polarity, creating a push/pull force on the magnets. The resulting force is capable of moving an object without making physical contact. This force generates a linear motion when using a flatbed track of magnets and a rotary motion when using a curled-up ring of magnets. The applications may be different, but the technology is exactly the same.

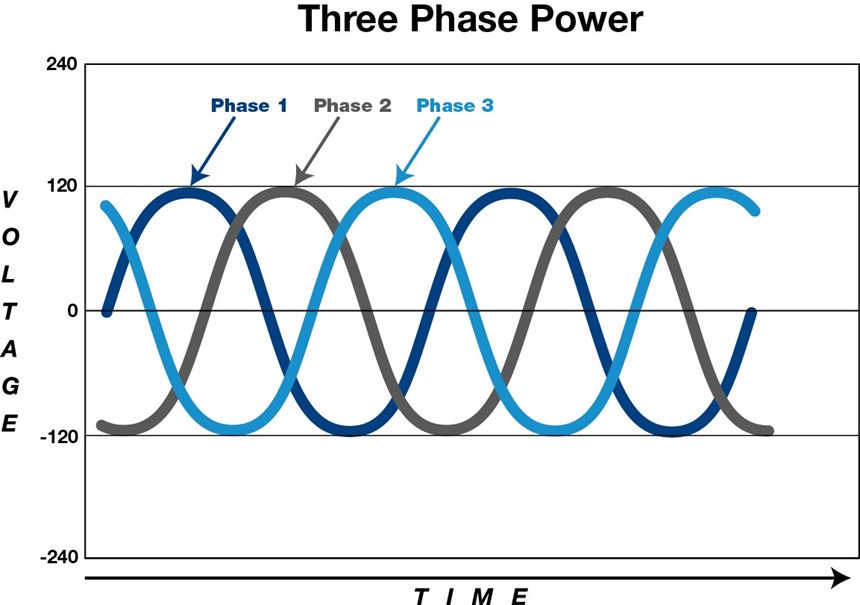

Each coil is called a pole, and to get the desired motion, their polarity and strength need to be changed relative to the magnets to maximize the force delivered. The standard today calls for three different coil behaviors, called phases, acting upon the magnets at the same time. For this reason, the type of motors using this method are referred to as three-phase synchronous motors. All that a motor has as an input when it comes to performance are three wires for current and, for this reason, motors do not have any compatibility issues with different controllers.

Once the working principle is understood, it is easier to see the benefits of this technology, including the large force density it brings. With the motor having only two parts (the magnets and coils) they are compact for the power they deliver. The small moving carriage of a linear motor and the large hollow shaft of a torque motor allow the payload to be mounted directly to the motor, optimizing the space within the machine. This placement also delivers a high mechanical stiffness and allows for a more dynamic range of motion since the forces are not being transferred through multiple parts. Another benefit is the elimination of backlash and inertia mismatch. A force transmission method that can perform over a range of force and speed without having to make mechanical adjustments, and whose performance and precision is only limited by the feedback device to which it is attached, is the result.

Despite its benefits, direct-drive technology is not more widely adopted because of the upfront price and complexity of integration. Because of cost of material (mostly the permanent magnets) there is often a hesitation toward making the investment to switch over. Additionally, when someone is already familiar with a gearbox or ballscrew solution, its familiarity can be comforting.

While those two factors can create some intimidation from the start, what needs to be understood is that a lot of the value from direct drive comes from its long-term use. By maximizing a machine's performance, the manufacturer greatly increases a machine's throughput and reduces the occurrence of interrupted cycles from machine downtime for maintenance and part failures. When properly integrated, the user has a motor that could be operating 10 years down the line and will perform just as well as one that is newly installed.

To get the most out of direct-drive technology, its limitations must also be understood. The concept of the force transmission being coupled directly to the payload can be compared with the concept of semi-closed loop when it comes to encoders. The fewer the degrees of separation between the part, the greater the overall performance will be.

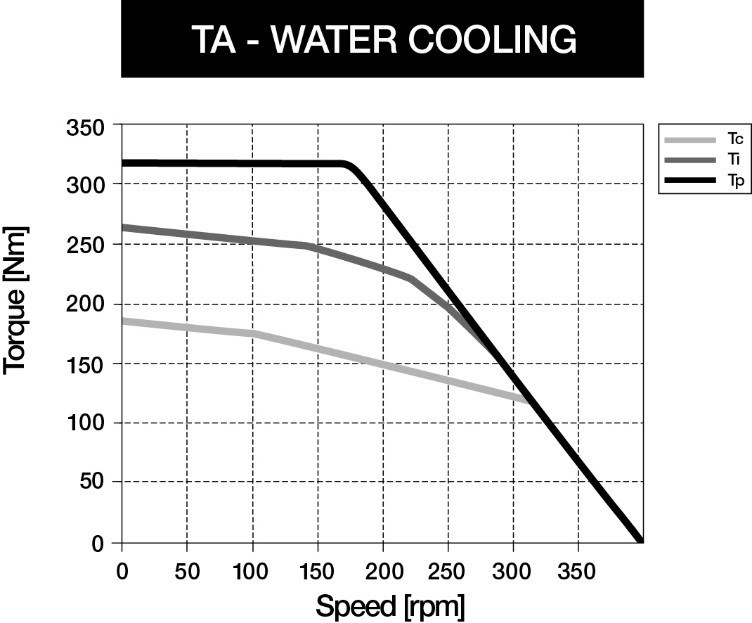

Most of the time, a motor’s performance is limited by how much force/torque a motor can output without overheating. The continuous value of the motor (continuous force with linear and torque with rotary)—the average value at which a motor can run 24/7—is the most malleable since it depends on how the motor can dissipate heat. If the motor has some type of heat sink or is liquid cooled, performance will increase noticeably, sometimes even doubling with liquid cooling due to how much heat is dissipated.

A motor can perform above the continuous value, up to the peak value, but is physically unable to go higher than the peak value, typically because that is the point where so much current is added to the coils that the magnets may be demagnetized. Although not as flexible as the continuous value, the time it takes a motor to reach the peak varies from as long as two seconds to tens of milliseconds.

Speed is one more value that can vary the performance. When the magnets move past the copper coils, a current is created within the copper and creates a back-electromotive force (back-EMF) voltage. To compensate, the controller must input more current to counteract this current normally used to give the motor its power. The result is that the higher the speed at which the motor operates, the more difficulty it will have reaching similar force values. The larger the surface area between the magnets and coils, the more back-EMF, which is why a motor has lower speed capabilities as it gets larger or has more poles. Although size is not the only property that affects performance (eddy currents can occur and heat up parts of the motor), it does have the greatest impact.

An understanding of this technology and its benefits and important parameters allows better decision making around the level of investment that makes the most sense for a machine's design. In many industries, from machine tools to aerospace to semiconductor applications, this technology has shown the ability to increase the quality of manufactured products. As the standard of quality increases, machines will need to adapt to technologies that can help them meet these requirements. Direct drive will be a part of this transition for years to come.

About the Author

Brian Zlotorzycki

Brian Zlotorzycki works as a product specialist for the components area of Etel S.A., a subsidiary of Heidenhain.