Published

The Joyful Dawn of a New Era

A successful cleaning process removes soil without leaving harmful residue and damaging the product. By using a consumer or household product in an industrial or critical cleaning process, you may sacrifice productivity and increase costs.

Cleaning Consultants,

BFK Solutions

For many manufacturers, setting up a cleaning process, even for a critical product, involves a trip to the grocery store or home improvement center to purchase household detergent or liquid dish soap. You might ask, what’s wrong with that? Especially if the process is working, why not let sleeping dogs lie?

In a nutshell, a successful cleaning process removes soil (matter out of place) without leaving harmful residue and without damaging the product. Following are some ways in which household products are not optimized to critical and industrial cleaning.

Countless additives can be used in aqueous formulations; you want products with additives most beneficial to your cleaning application. Many manufacturers find that a bit of time invested in comparing aqueous cleaning chemistries is well spent in that they end up with an additives package geared to their product line.

Even if you are using an immersion process bath, there can be problems with bath life in that dish soaps tend to hold soil in suspension. In contrast, many industrial cleaning agents are designed as “oil-splitting” chemistries. That is, the chemistries are designed so that the oil pops up to the surface so that it can be removed, leaving a clean process bath. Of course, if you currently clean in a simple immersion tank, when you switch to an oil-splitting chemistry, you may also need to modify the process so that you are not re-soiling product by dragging it through a layer of oil. The most efficient way to remove the oil involves a sparger or weir; this involves some investment in process equipment.

Even if a consumer product appears to be less expensive, consider the costs of changing out the process bath, including labor time and costs to dispose of the spent cleaning agent.

Finally, the soil loading capacity of a consumer cleaning agent may lead to a false sense of security and may mask bath degradation. The capacity for a degree of soil loading is necessary for practical cleaning processes. However, there can be too much of a good thing. Because consumer products typically hold soils in suspension, there can be problems related to overloading of soils and redeposition of soils on the part.

Consumer cleaning agents are designed to remove typical consumer soils from typical household items. They are designed for cleaning dishes or perhaps for quickly wiping surfaces. Even if the product appears to remove soils effectively, it is important to evaluate the potential for substrate damage by testing the product with all of the materials of construction that will be exposed to the cleaning chemistry.

not be greeted kindly.

You might try contacting the supplier for product support. Several manufacturers of household cleaners used in industrial and critical cleaning applications were contacted to see if someone in an applications lab could be reached. In several cases, a chemist or product support specialist was unable to be accessed and, after repeated requests, emails and time spent on hold, some suppliers of household cleaning product either verbally or in brief e-mails indicated that they did not support the products for industrial assembly processes.

In addition, the quality of support for products sold for critical and industrial applications can vary as well, so it is helpful to check the availability of laboratory support for all cleaning chemistries.

• Familiarity—If the dish soap removed last night’s burnt-on dinner, it might seem reasonable to try it for burnt on lubricants. If it appears to work, assemblers continue to use it.

• Convenience—Particularly for small-scale processes, it may be easier to pick up a case of discount industrial cleaner at the “big box” store than to place an order with a distributor.

• Advertising—We live in an age of advertising and most of us are probably responsive to publicity. We have also seen examples where a cleaning agent was selected because it had the same name as the supervisor. We observed the power of the infomercial in the course of a comparison study of aqueous-based products for point of use or hand-wipe cleaning. One client was using a water-based spray cleaner that the operator had found on a late-night infomercial. We compared the product that supposedly worked with a number of other formulations and found it to perform, at best, marginally, even against the soils supplied by that client. The study was presented to the Joint Services Solvent Substitution Working Group (JS3WG) and is posted on their Web site (http://js3.ctc.com).

• Perceived safety or environmental friendliness—Other products have names that convey the concept of clean, or safe or ecologically-friendly. It is important to determine if the name is backed up by actual favorable safety or environmental attributes and if it performs acceptably in your application. One individual commented that a consumer-oriented cleaning agent had grit to remove heavy soils from his fingernails, but left his hands soft. However, because industrial cleaning processes often involve heat, force and time, a consumer-oriented cleaning agent used in an industrial process cannot be considered immune to worker safety issues. Even if the product itself is biodegradable and kind to the earth, your process bath contains environmentally-unfriendly items like soils, polishing compounds and metal fines. In many cases, you cannot simply dispose of a process bath as if it were a dishpan. Finally, even if the dish soap does not damage your dishes and leaves your hands silky-smooth, even if it is totally organic and contains no hazardous ingredients, it may damage the product. You may not see the damage, but your customer could see an increase in defects.

• Out-of-date cleaning processes—All cleaning processes, particularly aqueous processes, have to be optimized to the total build process. If any factors change, for example, a lubricant, the cleaning process may have to be modified. If the process is not working properly, and if the response from management is not rapid enough, it is very tempting to try a “patchwork” quick-fix from the local hardware store. If it seems to improve matters (at least visually), the product becomes an informal part of the process, but probably a poorly-controlled part of the process.

Barbara Kanegsberg, a.k.a. “the cleaning lady,” is president of BFK Solutions LLC (Pacific Palisades, CA), independent consultants in critical and industrial cleaning, surface quality and contamination control. Visit the Web site at www.Bfksolutions.com.

Why Not Use Household Cleaning Products for Industrial Processes?

Aqueous cleaning processes are most efficient when the appropriate chemistry for the soil and substrate (the part being cleaning) is selected. By using a consumer or household product in an industrial or critical cleaning process, you sacrifice productivity and increase costs. In addition, there have been too many instances of problems with build processes that could be traced directly to the use of consumer or household products. Sometimes, the problem chemistry was used during final assembly; in other cases, the source of inadequate cleaning or surface damage could be traced back to use of consumer chemistries at a sub-vendor/supplier. While we are covering primarily aqueous (water-based) products, some of the same concerns hold true for other cleaning agents that are based on organic chemicals such as mineral spirits or biobased chemicals.In a nutshell, a successful cleaning process removes soil (matter out of place) without leaving harmful residue and without damaging the product. Following are some ways in which household products are not optimized to critical and industrial cleaning.

Additives

Many household products contain perfumes, colorants and lotions to make the product more pleasant to use. However, such additives can leave a thin, overall surface residue that interferes with subsequent processes like coating or deposition. Even with rinsing, additives can become trapped in the nooks and crannies of the product, leading to assembly problems, yield issues or unexpected, catastrophic product failure.Countless additives can be used in aqueous formulations; you want products with additives most beneficial to your cleaning application. Many manufacturers find that a bit of time invested in comparing aqueous cleaning chemistries is well spent in that they end up with an additives package geared to their product line.

Suitability of Formulation to the Process

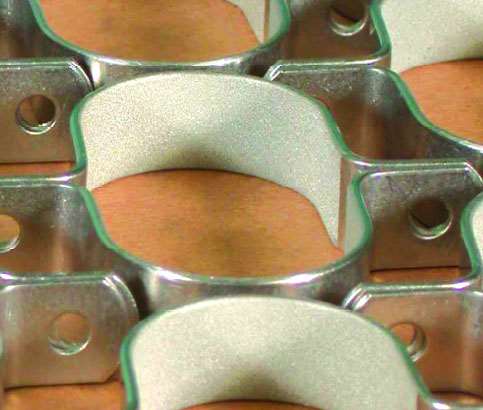

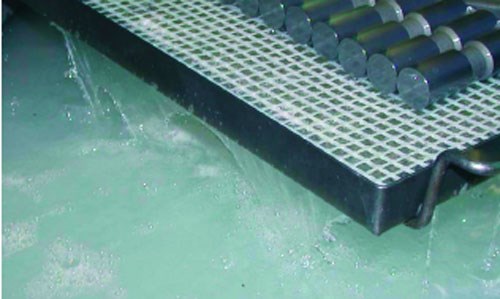

Household cleaning products that work in a dip tank may not adapt well to an upgraded process. For example, if you decide to adopt a high pressure spray, the appropriate defoamers must be present or unpleasant soapsuds will result. In addition, some cleaning agents for critical applications are designed specifically for ultrasonics applications.Even if you are using an immersion process bath, there can be problems with bath life in that dish soaps tend to hold soil in suspension. In contrast, many industrial cleaning agents are designed as “oil-splitting” chemistries. That is, the chemistries are designed so that the oil pops up to the surface so that it can be removed, leaving a clean process bath. Of course, if you currently clean in a simple immersion tank, when you switch to an oil-splitting chemistry, you may also need to modify the process so that you are not re-soiling product by dragging it through a layer of oil. The most efficient way to remove the oil involves a sparger or weir; this involves some investment in process equipment.

Even if a consumer product appears to be less expensive, consider the costs of changing out the process bath, including labor time and costs to dispose of the spent cleaning agent.

Finally, the soil loading capacity of a consumer cleaning agent may lead to a false sense of security and may mask bath degradation. The capacity for a degree of soil loading is necessary for practical cleaning processes. However, there can be too much of a good thing. Because consumer products typically hold soils in suspension, there can be problems related to overloading of soils and redeposition of soils on the part.

Balancing Cleaning and Substrate Damage

Industrial processes strike a balance between aggressive soil removal and damage to the substrate. Particularly in choosing the optimal aqueous cleaner for a given application, it is crucial to specify the material(s) being cleaned and the metalworking fluids and polishing compounds being used.Consumer cleaning agents are designed to remove typical consumer soils from typical household items. They are designed for cleaning dishes or perhaps for quickly wiping surfaces. Even if the product appears to remove soils effectively, it is important to evaluate the potential for substrate damage by testing the product with all of the materials of construction that will be exposed to the cleaning chemistry.

Unexpected Formulation Changes and Product Support (or LackThereof)

For years, a dish washing detergent was successfully used to clean critical aerospace subassemblies. Then, the word “improved” appeared on the label, a citrus scent was apparent and the cleaning process stopped working. In this actual ‘legend of aerospace,’ the contamination source was apparent. Sometimes, unannounced formulation changes are not so quickly identified; valuable time and product can be lost before a cause of the process failure is found. What if this happened to you? You might find another process, but if you had qualified the household cleaner with your customer, such an emergency change mightnot be greeted kindly.

You might try contacting the supplier for product support. Several manufacturers of household cleaners used in industrial and critical cleaning applications were contacted to see if someone in an applications lab could be reached. In several cases, a chemist or product support specialist was unable to be accessed and, after repeated requests, emails and time spent on hold, some suppliers of household cleaning product either verbally or in brief e-mails indicated that they did not support the products for industrial assembly processes.

You May Be Surprised

Check on the availability of product support before you need it, because you may be able to set your mind at ease. There are some “crossover” products. A few household cleaning agent manufacturers actually provide process and laboratory support; sometimes there is a genuine chemist you can speak to. If you like a household product, they may be able to suggest a similar formulation that is better suited to industrial or critical cleaning applications.In addition, the quality of support for products sold for critical and industrial applications can vary as well, so it is helpful to check the availability of laboratory support for all cleaning chemistries.

Why Some Choose Consumer, Household Products

In most cases, you could improve quality, profitability and outshine the competition by selecting an aqueous product designed for industrial and critical cleaning applications. So why do people continue to use household products?• Familiarity—If the dish soap removed last night’s burnt-on dinner, it might seem reasonable to try it for burnt on lubricants. If it appears to work, assemblers continue to use it.

• Convenience—Particularly for small-scale processes, it may be easier to pick up a case of discount industrial cleaner at the “big box” store than to place an order with a distributor.

• Advertising—We live in an age of advertising and most of us are probably responsive to publicity. We have also seen examples where a cleaning agent was selected because it had the same name as the supervisor. We observed the power of the infomercial in the course of a comparison study of aqueous-based products for point of use or hand-wipe cleaning. One client was using a water-based spray cleaner that the operator had found on a late-night infomercial. We compared the product that supposedly worked with a number of other formulations and found it to perform, at best, marginally, even against the soils supplied by that client. The study was presented to the Joint Services Solvent Substitution Working Group (JS3WG) and is posted on their Web site (http://js3.ctc.com).

• Perceived safety or environmental friendliness—Other products have names that convey the concept of clean, or safe or ecologically-friendly. It is important to determine if the name is backed up by actual favorable safety or environmental attributes and if it performs acceptably in your application. One individual commented that a consumer-oriented cleaning agent had grit to remove heavy soils from his fingernails, but left his hands soft. However, because industrial cleaning processes often involve heat, force and time, a consumer-oriented cleaning agent used in an industrial process cannot be considered immune to worker safety issues. Even if the product itself is biodegradable and kind to the earth, your process bath contains environmentally-unfriendly items like soils, polishing compounds and metal fines. In many cases, you cannot simply dispose of a process bath as if it were a dishpan. Finally, even if the dish soap does not damage your dishes and leaves your hands silky-smooth, even if it is totally organic and contains no hazardous ingredients, it may damage the product. You may not see the damage, but your customer could see an increase in defects.

• Out-of-date cleaning processes—All cleaning processes, particularly aqueous processes, have to be optimized to the total build process. If any factors change, for example, a lubricant, the cleaning process may have to be modified. If the process is not working properly, and if the response from management is not rapid enough, it is very tempting to try a “patchwork” quick-fix from the local hardware store. If it seems to improve matters (at least visually), the product becomes an informal part of the process, but probably a poorly-controlled part of the process.

So What Should You Do?

How should you herald the joyful dawn of a new era? Do not wait for a problem to arise. Review the written documentation. We have observed consumer products that are immortalized in aerospace documentation for critical assemblies—the documents often date back a generation or so. Next, and this is even more important, actually tour the fabrication areas. If you are a final assembler and use sub-vendor suppliers for part of the assembly and/or cleaning, contact them and perform a site visit there, too. If you find consumer- oriented cleaning products, flag those products, noting the brand, supplier, source and contact information. Then, contact the manufacturer or supplier and determine the level of technical support. If product support is not available, make plans to change the process.Should You Let Sleeping Dogs Lie?

No. However, wake them gently. It is generally counterproductive to simply mandate immediate changes unless there is an urgent process or yield problem or a compliance issue. It is more effective to work with the technicians, the operators and the assemblers to determine why the consumer product was introduced. Rather than placing blame (which makes people avoid fixing the problem), this approach can provide invaluable information as to what is actually needed to achieve critical cleaning and contamination control. Only then should you evaluate cleaning agents designed for industrial and critical cleaning and find more supportive suppliers.Barbara Kanegsberg, a.k.a. “the cleaning lady,” is president of BFK Solutions LLC (Pacific Palisades, CA), independent consultants in critical and industrial cleaning, surface quality and contamination control. Visit the Web site at www.Bfksolutions.com.