In an industry in which production time, volume and quality are critical, it’s increasingly important to ensure that metal parts obtain desired results and meet established specifications. Since metal parts cleaning is fast becoming the industry standard, facility managers must become well-versed in the extensive cleaning processes and chemistries available that will provide the performance level required. It is essential for these managers to learn the differences between aqueous and solvent cleaning solutions, and the advantages and disadvantages of using each approach.

Metal parts need to be cleaned after they are manufactured to remove oil, chips and other soils before they can be moved to a surface treatment such as coating or plating. They also sometimes must be cleaned to meet inspection and cleanliness specifications, and to prepare them for packaging/assembly. Requirements set by manufacturers might include critical performance, reliability, process requirements and personnel safety.

Featured Content

Recent increased demand for quality and reliability calls for continuous improvements. Superior cleaning performance (aqueous or solvent) requires cleaning compatibility with substrates, process efficiency and environmental compliance, as well as worker safety.

Chemistry First

For a chemical process to take place, it must include cleaning solution, soil compatibility, solution concentration, solution temperature, proper exposure period and required mechanical action. Cleaning performance is directly related to the selection of the cleaning equipment and proper chemical process. It takes the correct combination of all these ingredients to achieve maximum results related to meeting production, quality, personnel safety and environmental requirements.

To effectively use a cleaning chemistry, a facility manager must understand the benefits of and guidelines for using cleaning solutions in conjunction with available cleaning systems.

Aqueous Cleaning

General aqueous cleaning consists of blended water and water-soluble chemical components. These compounds can include additives (surfactants, solvents, acids, alkaline building agents and inhibitors) to enhance the process performance or meet specific needs. Ideal compounds are rated as low or no volatile organic compounds (VOCs), no hazardous air pollutants (HAPs), non-flammable or combustible, and no global warming potential (GWP). Normally diluted with water between the chemistry range of 2-15 percent, these cleaning products rinse easily with water. There are a number of these products on the market, and they are generally designed for use with all types of spray and immersion washers. Some companies add the use of ultrasonic cleaners or other types of mechanical action to enhance particulate removal.

Aqueous cleaning chemistries include emulsifiers, non-emulsifiers (oil-splitting), acidic (pH less than 4), mild-alkaline (pH of 9-12.5), neutral (pH of 4-9) and high-alkaline (pH greater than 12.5).

No cleaning machine will perform properly without the appropriate chemical process (cleaning solution, solution concentration, solution temperature, proper exposure period and any required mechanical action). It takes a combination of all facets to achieve maximum results for production, quality, personnel safety, and environmental compliance.

Typical aqueous cleaning systems are designed to match process needs such as:

- Production volume, parts geometry, parts size and material handling

- Type of chemicals to be used (alkaline/neutral/acid)

- Soils removal

- Waste streams for wash tanks

- Waste stream for rinse tanks

- Footprint and/or floor space

- Energy requirements.

When selecting cleaning equipment to provide appropriate mechanical and thermal energy, keep in mind that cleaning equals time plus temperature plus mechanics plus chemistry. The following features also should be considered:

- Recirculating of the wash solution

- Use of multiple rinse stages

- Drying system design vs. throughput

- Centralized unit vs. cellular system.

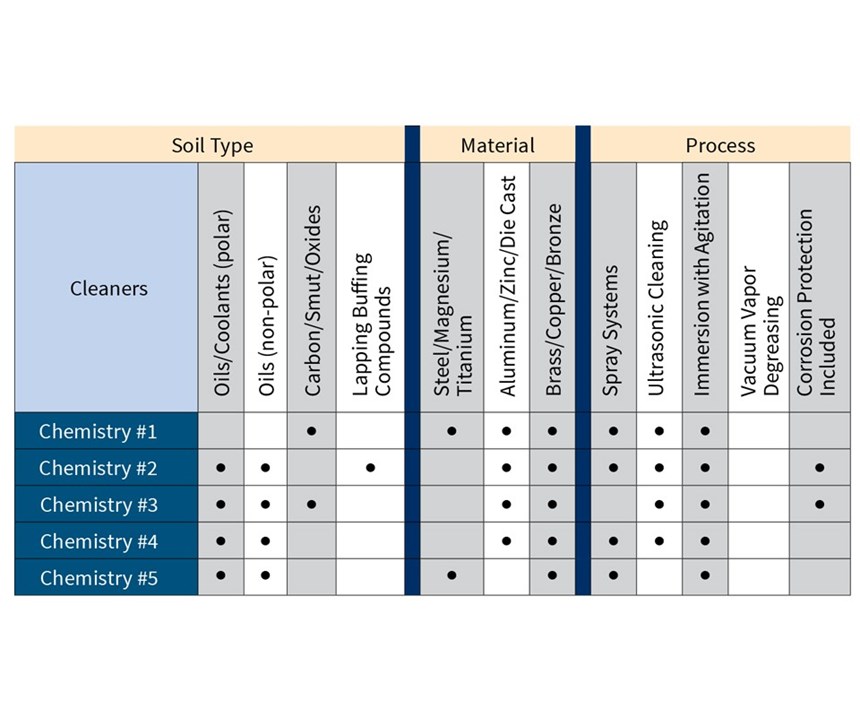

Consider developing a matrix like the one below to identify the best options for your manufacturing application.

Solvent Cleaning

General solvent degreasing also is a process many manufacturers use today. Today’s cleanliness specifications for precision and critical cleaning indicate that most metal parts cannot have any contaminant residue or rinse water residue, thus increasing the interest in solvent-cleaning agents. In addition to the meeting the cleanliness specification mentioned here, solvent cleaning also overcomes water’s inability to properly perform to certain other criteria, issues related to component spacing and restrictive drying processes. Materials compatibility is similarly a major area for concern, and solvent has proven to provide superior results in some cases.

Unlike aqueous cleaners that must be matched to specific process substrates, solvents generally offer:

- Multi-metals compatibility

- Multiple elastomers compatibility

- Multiple lubes-removal compatibility

- Ease of application

- Assured drying

- Very low surface tension

- Lower energy consumption and therefore lower cost of operation

- Less floor-space requirement.

New Solvents vs. Old Solvents

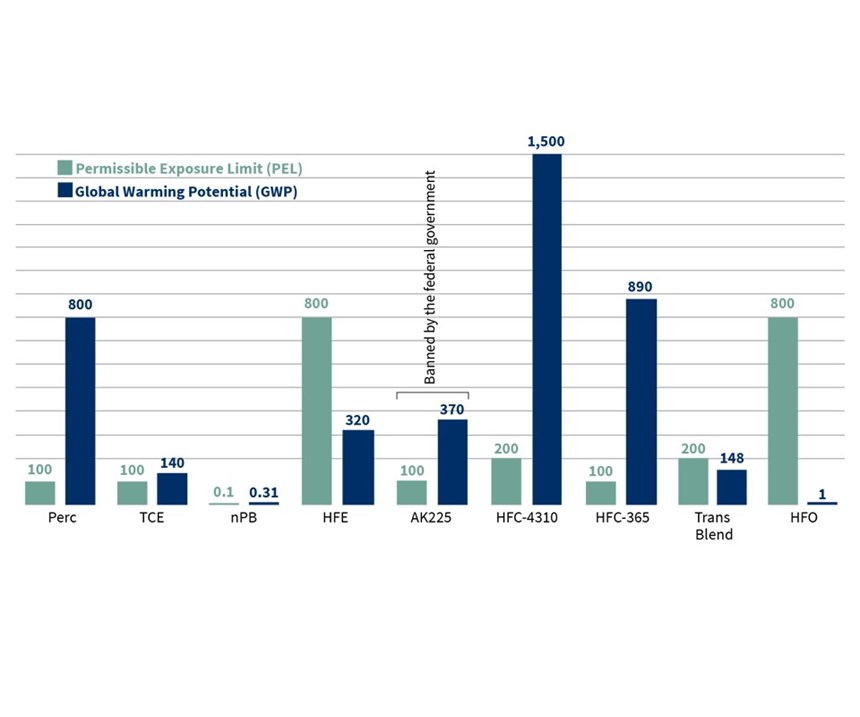

There are several solvents commonly used in the parts cleaning industry. Their requirements range from low to high operational temperatures, and their chemical compositions can include chlorinated, brominated, fluorinated, alcohol and others. The main difference among them are their environmental and health characteristics. Most solvents will clean, however, numerous solvents are being phased out or are becoming more regulated because of personnel exposure limits and air emissions. Users today are evaluating these new options in order to provide a safer workplace.

Based on regulatory concerns, many chemical manufacturers have devoted resources to research and development efforts. Recently, a new generation of solvents has emerged. These emerging new solvents include hydrofluoro-olefins (HFOs), hydrofluoroethers (HFEs) and trans blends. Some contain no chlorine, bromine or fluorine, such as modified alcohols and refined hydrocarbons. They are used in vacuum degreasers, which can drastically reduce solvent consumption as well as offer the operator maximum isolation from the process.

The highest-rated new solvents offer the following features:

- high PEL limits for personnel safety

- low GWPs

- low surface tension

- very low VOC or VOC-free ratings

- non-flammable

- low carbon footprint contribution

- lower-temperature operation

- compatibility with multi-metals/lubes

- rapid drying (and generally residue-free)

- stability.

The chart above compares typical solvent types available in today’s market.

Choosing Aqueous or Solvent Cleaning

Whether to use an aqueous or a solvent process is the metal parts manufacturer’s choice, of course, but the right chemistry will help improve parts cleaning. The many characteristics and different aspects of the two types of processes have to be evaluated. Compatibility and efficiency testing should be performed before a new process is selected. Such tests could prove that a process is superior to another and/or indicate that a process isn’t the most appropriate for the specific manufacturing needs.

There is an abundance of information available and easily accessible to help manufacturers determine which cleaning method bests suits their needs, from government resources to environmental organizations to equipment and chemical suppliers to technical papers and consultants. Use these resources to supplement your decision-making.

RELATED CONTENT

-

What Does 2021 Have in Store for the Parts Cleaning Industry?

With a new opportunity to do good things in your organizations this year, I hope you use the parts cleaning section and this year’s and last year’s Parts Cleaning Conference as tools to succeed.

-

The Importance of Drying Parts After Cleaning

Most cleaning processes consist of three steps, not two: wash, rinse and dry. That drying step is absolutely necessary for everything from product finishing to product performance to effective throughput to product quality.

-

VIDEO: Vapor Degreasing Process Uses TCE Replacement to Eliminate Hazardous Waste

A solid relationship with a solvent manufacturer has aided Electro-Spec Inc. with the implementation of a trichloroethylene replacement material in its vacuum degreasing unit to clean a customer’s micromachined parts more efficiently.