Through-Coolant for Swiss Machines

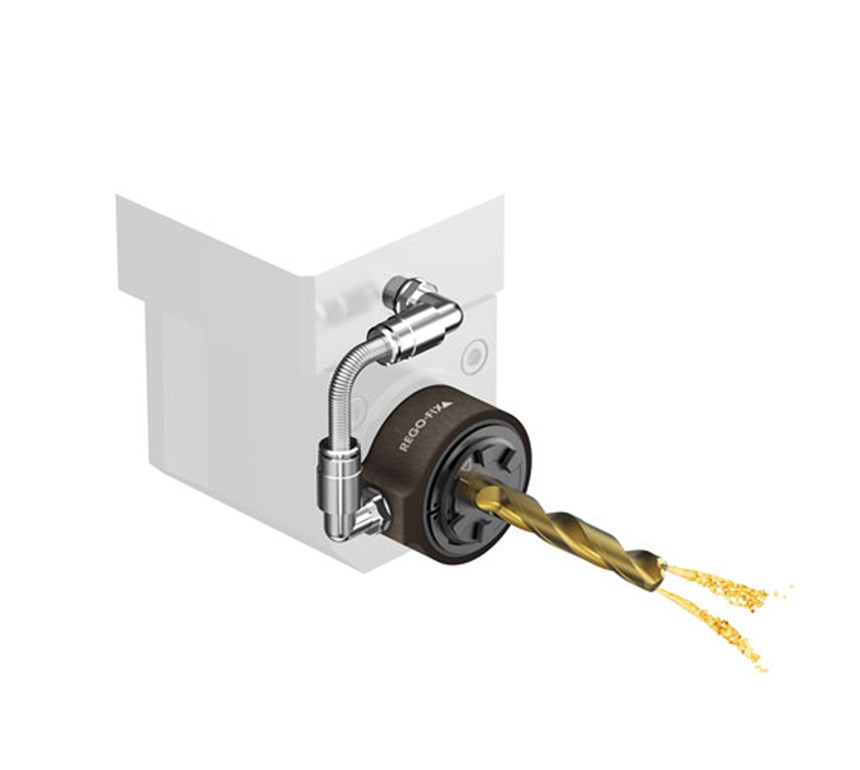

This system allows shops to quickly transform the standard external-coolant live tooling heads on their turning machine turrets into those with through-tool-coolant capability.

When trying to optimize CNC turning and Swiss automatic machining operations, even something as simple as coolant can impact the bottom line. When applications involve extreme speeds, feeds and temperatures, the use of coolant can enhance production efforts and reduce manufacturing costs.

The reCool system from Rego-Fix offers an alternative to what can sometimes be expensive, high-maintenance, through-coolant-dedicated live tooling heads. The system allows shops to quickly transform the standard external-coolant live tooling heads on their turning machine turrets into those with through-tool-coolant capability.

Featured Content

Swiss Specific

The company has recently introduced the reCool RCR-ERM model to its line of retrofittable coolant-through systems. This model provides all the benefits of the original technology to Swiss-type machines, but also allows the use of emulsion or pure oil.

Like its companion system, the new RCR/ERM cost-effectively converts existing flood-cooled driven tools with ERM mini threads to being through-tool-coolant capable in as little as two minutes. The system gets coolant to the cutting edge more effectively than spray piping or nozzles, and thus removes heat from the cutting zone and contributes to better surface finishes, longer tool life, improved chip control and increased productivity.

The reCool Mini accommodates standard speeds up to 12,000 rpm and coolant pressures as high as 1,450 psi/100 bar (2,150 psi/150 bar, optional).

Reviewing the Technology

With reCool, shops gain all the benefits of through-the-tool coolant delivery—longer tool life, more efficient chip control and less heat generation for faster speeds and feeds that lead to shorter cycle times and increased productivity. Plus, they avoid the high initial cost of dedicated through-coolant heads as well as the required routine maintenance (O-rings and lubrication), along with the complete system rebuilds that are regularly needed.

The maintenance-free system uses only four components—a special clamping nut with outer ring, coolant pipe, straight fitting and elbow fitting—and retrofits onto existing live tooling heads (straight and angled). The system requires that live heads have an ER output.

The system’s four different kit connectors thread into all of the industry’s common types of live heads with straight thread holes. Rego-Fix also offers a range of specially designed adapters for other manufacturers’ systems.

Ideal holders for use with the system are those with internally threaded regular ER-type nuts that are used by about 50 percent of the market on turret angled and straight live heads for turning machines. Any standard ER collet works with the system, which accommodates collet sizes from ER 16 through ER 40 while handling maximum cutting speeds of 6,000 rpm and delivering coolant pressures as high as 300 psi.

How it Works

reCool works using coolant-inducing technology. Through its special clamping nut, the system induces a tooling head’s external coolant supply into the collet holder cavity. Also, because the system brings the coolant in through the collet cavity, it prevents coolant from seeping back into the internal compartment of the live tooling head. Such seepage is what leads to the maintenance issues of dedicated through-coolant heads.

Along with standard ER collets, for drilling reCool uses Rego-Fix’s sealing disks that snap into the system’s clamping nut and can be exchanged to match drill shank diameters for sealing and directing coolant through the drill. For milling, the company’s coolant flush disks, matching end mill diameters, snap into the nut and channel coolant flow down along the shank and side of the tool.

The clamping nut does not require gaskets or O-rings, making it and the entire system maintenance free. Instead, it uses the coolant as a seal and bearing. During system operation, machine tool coolant fills a small gap between the rotating component and the mating stationary nut. Once the gap is full, a liquid bearing forms and reduces friction and dissipates heat caused by system rotation. It also maintains lower operating temperatures to preserve internal components.

reCool works with basically any level of coolant pressure, as long as the coolant is filtered and a strong, consistent flow is maintained. Also, during operation, the machine’s coolant system experiences no loss of pressure. The only other key system requirement—because it uses coolant as a bearing—is that the machine tool’s coolant must be switched on and flowing prior to starting a cutting tool’s rotation in the live head.

Benefits

The system has demonstrated higher efficiency than flood coolant to increase machine production. External flood coolant can be messy and time consuming, requiring machine operators to interrupt the process to re-adjust coolant nozzles. Getting the spray close to the cut zone is often impossible.

Through-coolant tooling and the reCool system always keep coolant pinpointed at the cutting tool’s edge and precisely in the cut zone to evacuate chips and reduce heat, which ultimately shortens part machining cycle times. When drilling a deep hole, through-tool coolant eliminates having to engage a time-consuming pecking operation to pull chips out of the hole and relieve built-up heat. Shops can drill holes more quickly in one continuous feed. Also, because through-tool coolant controls heat better, parts can be machined at much higher speeds and feeds without the risk of excessive heat generation or premature tool wear.

RELATED CONTENT

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.