When One? When Two?

East Branch Engineering often uses live-tool turning centers to complete complex parts in one setup. However, it also leverages a flexible and reconfigurable “mini-cell” strategy to enable a single operator to tend two machines at once, essentially gaining “free” machining time by overlapping operations.

There are complex jobs that East Branch Engineering feels it must run on its turning centers with live tooling. Many of these parts have tight feature-to-feature tolerances that make it essential to perform turning, milling, drilling and other operations on one machine in one setup.

That said, there are other instances in which running parts across two machines is either an alternative to the live-tool lathes or, in some cases, is a strategy that enables the shop to score some “free” machining time. For these applications, the New Milford, Connecticut, shop uses a reconfigurable “mini-cell” approach with a pair of portable CNC milling machines that can be easily transported next to any of the shop’s conventional VMCs or turning centers and then perform secondary operations, run dedicated, small-batch jobs or machine prototypes. That way, a single operator can tend two machines rather than standing idly by, waiting on just one machine to complete its operations.

Featured Content

Chris Guidotti, the shop’s vice president of operations, says this “cell-on-the-fly” approach also offers scheduling flexibility and can often more readily accommodate customers’ “hot” jobs if a live-tool lathe is tied up. As he explained during a recent visit, the mini-cell concept boils down to overlapping operations whenever feasible in order to get the most out of operators’ available time, as opposed to concentrating so heavily on minimizing cycle times or maximizing spindle uptime, as higher-production shops are more wont to do.

Leveraging Complementary Machining Strategies

Paul Guidotti, company president and Chris’ father, founded East Branch Engineering in 1989. Today, the shop has 22 machines and serves customers requiring medical, aerospace, printing and high-voltage power-supply components and assemblies. It focuses on prototyping and small to medium-sized batch production work, and accommodates a variety of metal and plastic materials.

Years ago, the split between repeating contract work and miscellaneous job shop work was 70/30. Today, it is closer to half and half. This is largely because the company is trying to expand its customer base by pulling in work from other industries, Chris says. This, in addition to shrinking lot sizes, is one reason why process flexibility is becoming increasingly important to the shop.

Of course, process flexibility has always been top of mind at East Branch Engineering, Mr. Guidotti explains. From the beginning, the shop has had a relatively small workforce compared to the number of machines, believing operators should be equipped to tend more than one machine at a time. So in that respect, the concept of overlapping operations by creating mini cells on the fly isn’t new. The shop had always envisioned using some sort of small milling machine that could be easily located next to the shop’s other primary machines so an operator could tend two, using that portable machine to perform secondary operations or to run different, perhaps unexpected hot jobs.

In fact, it purchased a compact machine for this purpose in 2000 and also added electrical drops near all of its primary equipment to power that machine as needed. However, the shop found the portability of that particular machine to be lacking. Plus, it didn’t have an automatic toolchanger, so operators needed to change tools manually.

As a result, East Branch Engineering tabled the mini-cell approach for the time being and purchased its first live-tool lathe in 2004. The shop was increasingly going after and winning more complex work, and this platform enabled tricky parts to be machined complete in one setup, ensuring the level of feature-to-feature accuracy that might not be possible running parts across two or more machines.

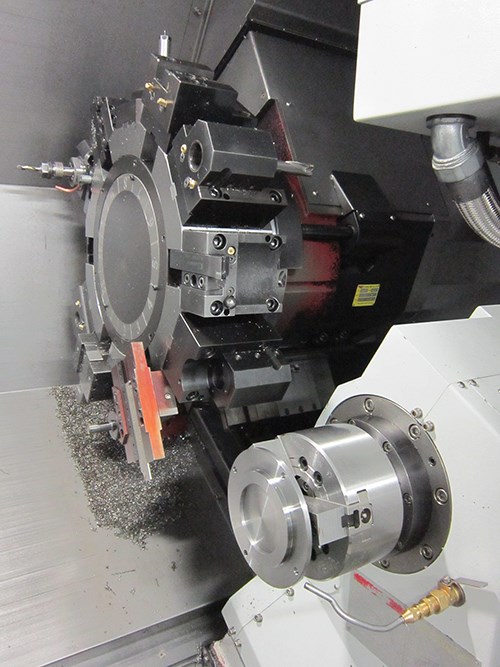

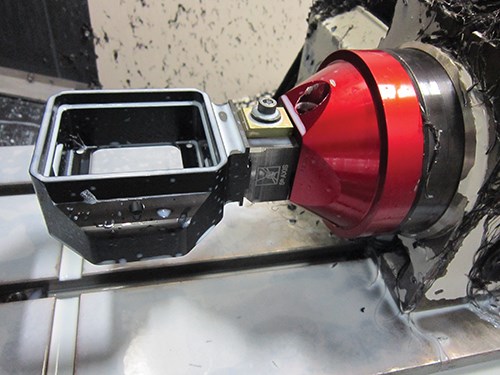

A good example of such a part is shown above. The shop currently machines this steel hub complete on its Feeler HT-30SY twin-spindle turning center purchased through Methods Machine Tools. This machine features a 30-hp main spindle, a 6,000-rpm subspindle, Y-axis motion and a 12-station BMT turret with 10-hp live-tooling capability at each station.

Mr. Guidotti says the shop uses the twin-spindle machine for this part because of the tight orientation tolerances with respect to the keyway, shaft and mounting hole locations. With this machine, it’s possible to complete the part in one setup, meaning the orientation between those features is essentially “dialed-in.” On the other hand, completing the milled features on a VMC would require orienting the part between two milling operations with two setups and two fixtures, leading to multiple chances for positioning error stack-up.

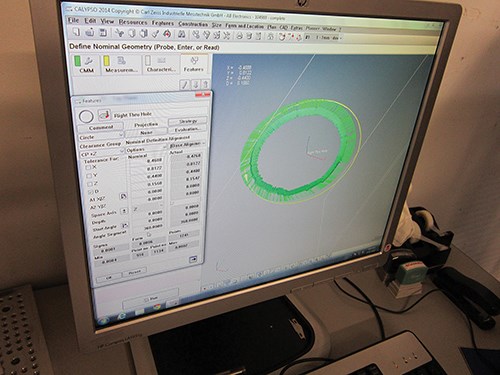

He notes there’s also an inspection benefit to completing parts like this on one machine in one setup: The part is measured only once. Conversely, multiple setups on multiple machines would mean that some features would be measured several times on the company’s shopfloor CMM (a Zeiss Duramax model). In the case of the hub, the shaft is a datum. So a multiple-setup scenario would require that datum to be probed after turning is completed and redundantly probed again after each subsequent milling operation, resulting in additional time lost to part inspection.

That said, there are downsides to using live-tool lathes, Mr. Guidotti says. Specifically, setups must be conducted by skilled personnel and also inherently take longer than with conventional machines. This makes it less appealing to produce parts that have relatively loose tolerances on those machines especially when batch sizes are small. And what happens if a live-tool lathe crashes or is down for maintenance? What’s the backup plan for getting parts that have traditionally been produced on that machine to customers on time? In addition, East Branch Engineering processes parts that require secondary operations that aren’t necessarily complex, but would otherwise require additional time-consuming setups on the machine that completed the preliminary operations.

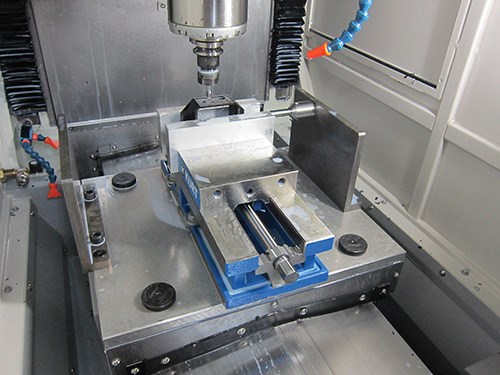

These and other reasons spurred the shop to revisit the mini-cell concept a couple years ago to complement its live-tool lathes. At that time, it happened upon a new compact machine platform that was more portable than the initial “portable” machine it had tried years ago. In 2013, East Branch Engineering purchased a Trak 2OP CNC milling machine from Southwestern Industries, one of two such machines it now owns. This machine is designed for secondary operations and short-run work, and includes a number of design elements that enables the shop to realize the type of maneuverability and flexibility it had been looking for in this type of machine all along.

One attractive element is its size. The 30-taper, 3-horsepower mill has XYZ travels of 14 by 12 by 17 inches and a footprint of just 2.5 by 4 feet, so it can be located in a small area near another machine that is convenient for an operator to access. It can also be moved to different locations using a simple pallet jack. (In fact, a pallet jack comes standard with each machine.)

Mr. Guidotti says it takes approximately 5 minutes to redeploy a 2OP to a new location near another machine. The process is simple: Power off the 2OP, unplug it, use the pallet jack to move it to the new location, re-connect the power supply (remember, the shop already had installed power drops next to every machine) and turn it on. Operators also first sweep the area so none of the machine mounts rest on chips. Plus, although the shop’s floor is fairly level, operators commonly re-level the machine once it is positioned at its new location.

The machine’s standard eight-station automatic toolchanger eliminates the need for manual tool changes, while an integral Jergens Ball Lock fixturing system, consisting of a subplate, fixture plate and shanks, facilitates quick change-overs. With this system, the shanks are inserted through liners in the fixture plate and into receiver bushings in the subplate attached to the machine table. Inside each shank are three balls that expand into a tapered groove in the receiver bushing with just a couple turns of a set screw to provide the holding force between the fixture plate and subplate and achieve positioning repeatability of ±0.0005 inch.

In addition to speeding setups, the quick-change fixturing system enables the shop to easily interrupt a run of one batch of parts and replace it with a customer’s hot job. To do this, an operator simply removes the fixture plate for the current job, saves the tool offsets to the control, installs the fixture plate for the new job, adds any additional tools that might be required, calls up the new job program and begins cutting. Plus, the machine’s Prototrak TMX controller with a conversational, graphical user interface makes it easy for an operator to leave the machine mid-setup and pick up where he left off. That’s because it won’t let an operator move to a subsequent step until he verifies that the previous step has been completed (see photos 11 and 12).

Mini-Cell Applications

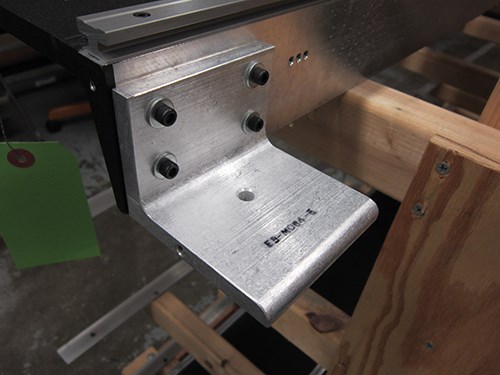

The angled part shown in the sixth image is one of the original components that the shop believed lent itself well to the two-machine, mini-cell strategy. Mr. Guidotti said it was because of the part’s simple side hole.

This part is used in an assembly for a large-format printer. Initial orders called for this part to be completed 10 at a time. However, when orders increased to 30 per batch, the time to complete primary machining operations then perform a second setup just to drill the side holes proved too lengthy. Now, whenever this job comes up again, the shop creates a mini cell using a 2OP machine to drill side holes in workpieces that have been partially completed by another VMC, having one operator tend both machines.

Mr. Guidotti admits there’s an argument to be made for developing fixturing to hold multiple workpieces for this part and enable the primary machine to drill the side holes. However, that means time must be devoted to designing and manufacturing the custom fixture, and then the machine is still tied up performing a very basic operation instead of more complex work. So, in this case, using the portable machine to drill the side holes one part at a time makes more sense (all the while realizing the “free” machining time the shop is always hoping to score).

East Branch Engineering holds weekly production meetings with key personnel including machine operators to discuss jobs in the queue and options for completing them without compromising quality. This typically includes a short conversation about the type of parts to be run that week, fixture considerations and the state of other jobs currently running at that time. Sometimes, a number of jobs with firm delivery dates are scheduled for production on the shop’s live-tool lathes. When that’s the case, it is impractical to break into that schedule to make 10 or so pieces for a new prototype or short-run job. Therefore, the shop will create a mini cell consisting of a conventional lathe and the 2OP.

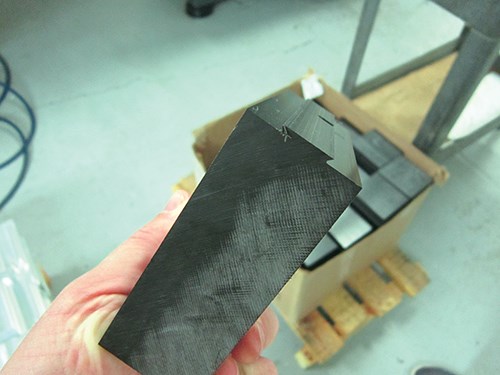

But while the portable machine’s name is “2OP,” and East Branch Engineering does often use it for secondary operations, the shop benefits from it in other ways as well. For example, it can be used as a standalone machine for relatively basic jobs or to pre-machine fixturing profiles in workpiece stock. The part shown in the eighth photo is an example. The 2OP machine creates the dovetail profile in the Delrin stock to enable workpieces to be fixtured in a mating dovetail in a workholding device from 5th Axis that’s fitted to a rotary indexer on one of the shop’s bigger VMCs. That VMC then performs primary pocketing and contouring work. Afterwards, the partially completed parts are delivered back to the 2OP to mill away the fixture dovetail and drill a few holes. Mr. Guidotti says this reduced the number of operations from seven to three compared to the previous method employed for this part. Plus, it doesn’t tie up a large machine just to perform such a simple, stock-prepping operation.

Becoming Effective With 30-Tapers

In addition to the portable mills, East Branch Engineering has a number of other 30-taper machines. Mr. Guidotti explains that the shop’s experience with these machines enabled it to use the portable machines effectively from the start. The keys are tooling and programming software.

For example, any weaknesses in the tooling is amplified in a 30-taper machine more than in machines with larger spindle interfaces. So while one might get by using a slightly damaged collet in a 40-taper, that likely won’t be the case with a 30-taper. He says the shop strives to use very compact toolholders (some harmonically damped) and short tools for maximum rigidity.

The shop also finds value in applying the Volumill toolpath strategy from Celeritive Technologies when programming with its GibbsCAM software. A Volumill tool path maintains a near-constant volumetric rate of material removal throughout the cut and contains no sharp corners. The resulting consistent tool load enables the use of more aggressive cutting parameters, regardless of the boundary geometry, which can significantly reduce cycle times.

Mr. Guidotti, who does much of the shop’s CAM programming, says he sometimes uses the software company’s Volumill Milling Advisor, developed in conjunction with cutting tool manufacturer Helical Solutions, which is a calculator designed specifically to be used with Volumill tool paths. This resource provides both conservative and aggressive cutting parameter recommendations based on material type, tool selection, machine tool capabilities and several other factors. This, in conjunction with effective tooling choices, enables the shop to obtain effective material removal rates and tool life out of its 30-taper machines.

RELATED CONTENT

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

-

5 Grinding Considerations for Improving Surface Finish

Improving surface finish can be done by making adjustments to one or more of these points: operational parameters, wheel dressing, grit size, coolant delivery and machine condition.

.jpg;width=70;height=70;mode=crop)