Rust Season Is Here: Take Care of Your Precision-Machined Parts

By: Wayne Siefert, President, Green Packaging, Inc.

To prevent corrosion from developing on the surfaces of freshly machined parts, it is crucial to create a barrier on the parts’ surfaces so moisture and oxygen don’t reach them.

#techbrief

5-Axis Machining Centers Transform Medical Swiss Shop

By: Lori Beckman

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth.

Growing Pains: A Process for Cutting Ties with Long-Time Employees

By: Jim Carr, President and CEO, CARR Machine & Tool

When your business is growing but a certain employee is not, it may be time to let them go. However, first stepping the employee through a process that includes warning and conversation with them is crucial.

#columns

Precision Ground Barstock: How It Is Manufactured, Benefits to Your Shop

By: Miles Free

Understanding the benefits provided by precision centerless ground barstock can help you avoid false economy and optimize the work you quote by maximizing benefits to your manufacturing process and customer.

#pmpa

Meeting Stringent Cleaning Goals With Modular Ultrasonic System

By: Doris Schulz, owner of Schulz Presse and journalist

A knee implant manufacturer implements an advanced cleaning system that meets its tight cleaning requirements, including documenting, validating and tracing the entire cleaning process.

Contest Seeks Innovative End-Use 3D Printed Parts

By: Stephanie Hendrixson

The Cool Parts Showcase is looking for 3D printed components that are currently in use or show promise as future solutions.

#additive

Applying a Healthy Approach to Employee Investment

By: Lori Beckman

Service Center Metals’ on-site health center offers its employees and their families free same-day health care and, in return, the employer is gaining many benefits including a healthier workforce and attracting potential employees.

#basics #workforcedevelopment

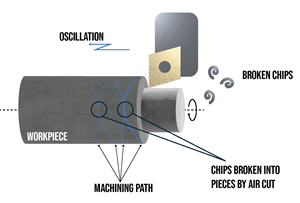

Getting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

How Small Machine Shops Can Fight Supply Chain Problems

By: Sandy Moffat, Chief Market Officer, CNC Software, LLC

Supply chain disruptions are still presenting challenges in manufacturing. This article examines the effects on aerospace, automotive and medical industries. It also covers ways that machine shops can be successful securing work despite the challenges created by the supply chain.

#columns

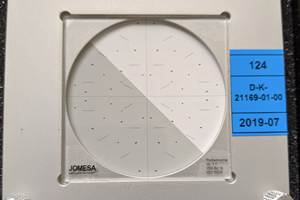

Overcoming 3 Common Challenges With Automated Particle Counting

By: Peter Feamster, product management director, Jomesa North America

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

#techbrief

Why Are We Writing About a Shop Making Custom Baseball Bats?

By: Derek Korn

I recently learned about a 153-year-old manufacturer that has produced billions upon billions of precision, metal pins which started another business making one-off wooden baseball bats. (Like I asked it to do for me and you’ll see at this year’s Precision Machining Technology Show). Here I explain why it’s worth the time to read that article.

#basics #columns #PMTS

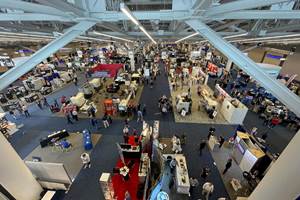

It’s Showtime!

By: Derek Korn

The 12th edition of the biennial Precision Machining Technology Show starts today. What might you discover there? What might I discover there?

PMTS 2023 Product Preview: Workholding

Edited by Angela Osborne

Learn about some of the latest workholding solutions that will be on display at PMTS 2023.

PMTS 2023 Product Preview: Toolholders

Edited by Angela Osborne

Learn about some of the latest toolholder solutions that will be on display at PMTS 2023.

Gardner Business Index: Precision Machining March 2023

By: Jan Schafer

According to information gleaned from Gardner Business Intelligence surveys, GBI: Precision Machining component activity generally continued in March the ‘right’ paths observed in February.

#columns

PMTS 2023 Product Preview: Measurement

Edited by Angela Osborne

Learn about some of the latest measurement solutions that will be on display at PMTS 2023.

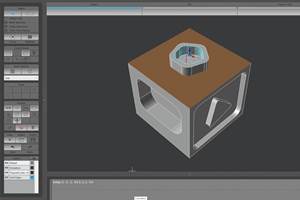

Can You Pull Data From a Solid Model to Perform Five-Axis Conversational Programming?

By: Derek Korn

A CNC feature imports a 3D solid model from which operators can perform conversational-type, five-axis programming.

#techbrief

Production Machining’s April 2023 News Highlights

Edited by Angela Osborne

Production Machining’s April 2023 news highlights include a special honor for a GBM stalwart, reshoring news, new technician training, workforce development funding and more.

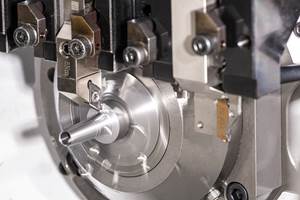

The Control’s Role in Machining Complex Parts

Edited by Lori Beckman

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

Video: Why a Production Machine Shop Started a Baseball Bat Company

By: Derek Korn

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

#horizontal-and-vertical-lathes #basics