A Visit to Hydromat Provides a Glimpse of New Technology

A visit to Hydromat Inc.’s Oktoberfest event in St. Louis provided a glimpse of the new Eclipse 12-100, the company’s re-imagining of the rotary transfer machine.

Traveling to St. Louis, Missouri can be fruitful for those wanting a glimpse of new technology on display. Along with Production Machining’s Editor-in-Chief Chris Koepfer, the afternoon of Oct. 24 was spent doing so with a visit to Hydromat Inc.’s Oktoberfest event and a glimpse at the new Eclipse 12-100, the company’s re-imagining of the rotary transfer machine.

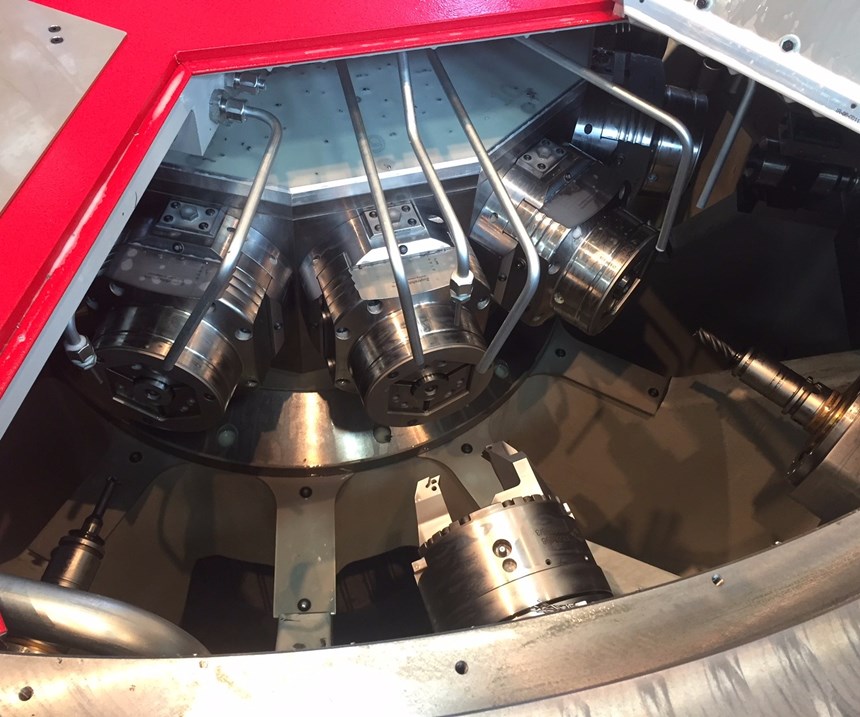

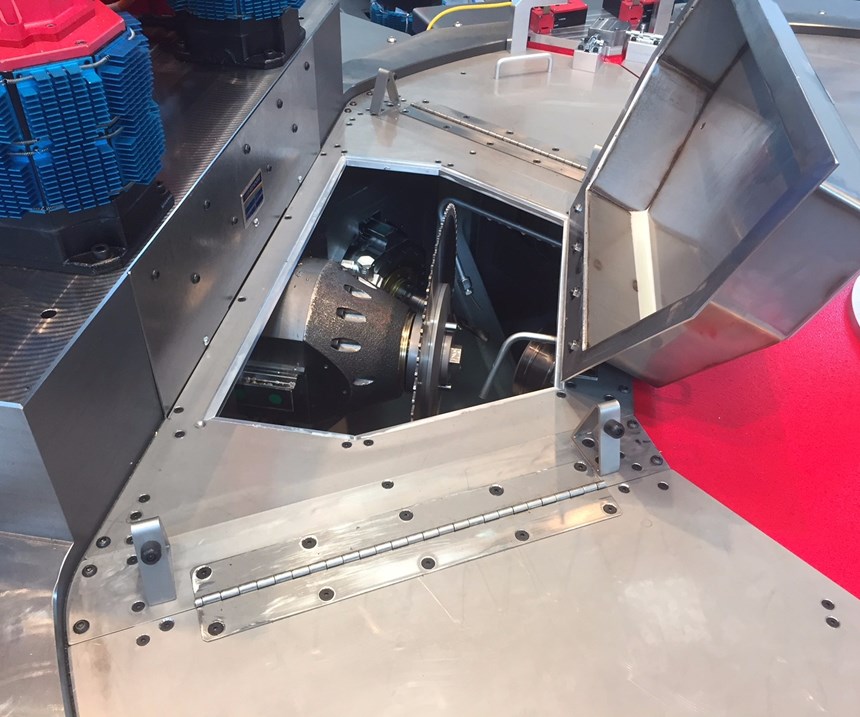

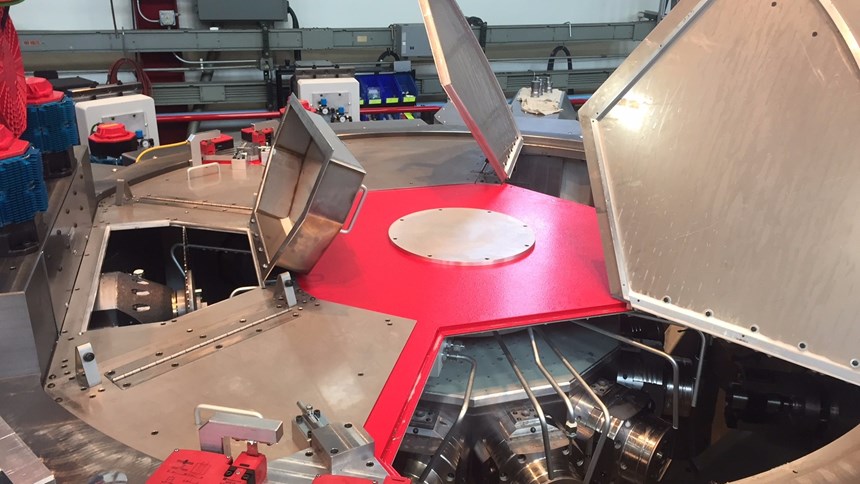

The Eclipse 12-100 is a ground-up redesign of the Hydromat concept with all new components. “It solves the problem of raggedy cuts,” says Kevin Shults, the director of marketing for Hydromat, with a focus on drilling and milling primarily. The casting is 2 meters in diameter, for instance, and is nearly twice as large as the traditional 12-station Hydromat machine.

“This is not a Hydromat,” says Mr. Shults. ”The Hydromat machine’s major components are made in Switzerland. The Eclipse is a St. Louis production with most parts made in the U.S., and others from all around the world.” And with that in mind, Mr. Shults is hoping to establish a beachhead in the U.S. and then sell into Switzerland and the rest of Europe, “Like the way they produce for us now,” he explains.

“We put everything we had into getting this going,” says Mr. Shults. The focus will be on the automotive, aerospace and fluid power type industries, with a focal point on IMTS next year.

Going to a site, seeing machines firsthand, and experiencing the advent of a new technology is the key to being a writer and editor for PM. Showing up is also important for establishing and cementing relationships with players in the manufacturing world. This kind of up-close-and-personal experience proves to be educational and keeps one tapped into the vein of the industry.