Automate to Eliminate Non-Value-Added Labor

Automation should free up employees to add even more, higher value-added items to your operations.

#workforcedevelopment

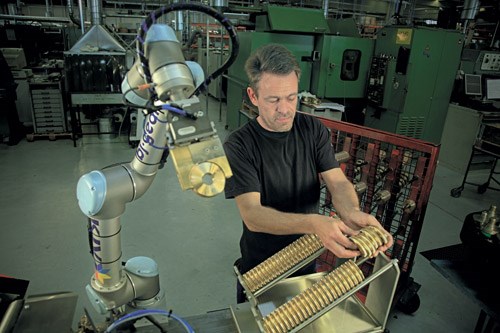

Photo courtesy of BJ Gear (Denmark).

“When we install this automated line, we can eliminate three jobs.” This is probably the stupidest thing that I have ever overheard. (I was eating lunch at a rest stop on the turnpike home from a recent trip.)

There are at least 600,000 high tech manufacturing jobs currently unfilled in the U.S. and Canada. We know there are about 391,000 baby boomer machinists that will be leaving the workforce in the next few years. Who in their right mind wants to eliminate people, especially when they have proven they can come to work, do the work and add value?

The point of automation isn’t to eliminate jobs. It is to eliminate non-value added labor. The employees have already demonstrated they can add value. Automation should free them up to add even more, higher value-added items to your operations.

I believe that people should be engaged at their highest and best use. Check out Norbert Wiener’s book, “The Human Use of Human Beings.”

The point of automation is to let you elevate your existing talent to their highest and best use. Anything else is “the eighth waste.”

Automate to elevate. Not to eliminate. Good people are hard enough to find.

Why would you eliminate your great ones?

Originally posted on PMPAspeakingofprecision.com blog.

RELATED CONTENT

-

Choosing an Automatic Bar Feeder

The bar feeder is the most common form of automation for turning operations. Selecting the right one requires consideration of the applications for which it will be used.

-

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

-

Automation in High-Mix, Low-Volume Turning Applications

Turning shops are familiar with automation for high-volume work, but the shifting landscape to smaller batch sizes has created new challenges.