CNC Machining and Motorsports

Have a look at some of the new manufacturing equipment spotted in “Machinery Row” at the recent Performance Racing Industry Show.

Seeing as though I’m the magazine’s resident “car guy,” you’re probably not surprised that I attend the annual Performance Racing Industry Show whenever I can, as I did last week. This year marks the 32nd edition of the show, which draws attendees from all 50 states and 70 countries. Many of the exhibitors are manufacturers and suppliers of equipment to support the motorsports industry. (The 2019 event at the Indiana Convention Center in Indianapolis featured 1,100 exhibitors in 3,000 booths.) That said, the show’s “Machinery Row” features manufacturing equipment and software such as machine tools, tooling, workholding devices, CAD/CAM packages and so on.

That’s where I spent the majority of my time at the show. Read through the the photos and descriptions below to see some of what I saw there. Much of it has broader potential applications than just motorsports. In addition, this Twitter thread includes video and some additional automotive eye candy.

Featured Content

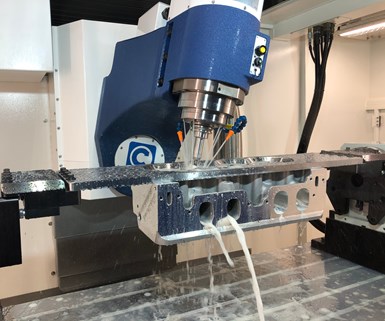

Full five-axis machining is often performed to shape and smooth cylinder head ports. This A590 machine from Centroid has a 180-degree articulating head and 40-hp/16,000-rpm spindle. Note the means by which the head is fixtured to a plate on the rotary indexer.

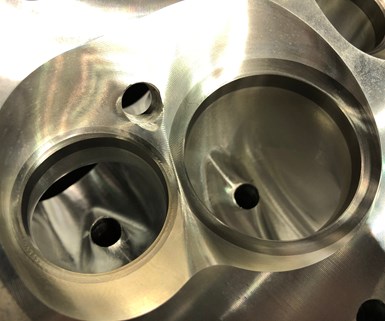

Here is an example of a combustion chamber’s contoured geometry and quality surface finish created via five-axis machining.

The sophistication of CNC machining technology on display at the PRI Show continues to increase. This L12 Swiss-type lathe from Marubeni Citizen-Cincom is an example. I believe it is the first Swiss-type I’ve seen displayed at the show.

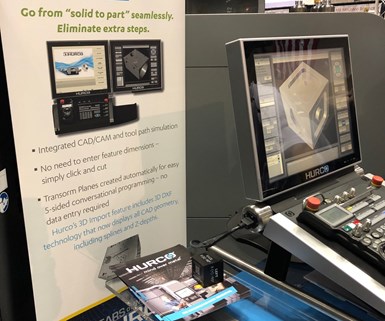

Hurco highlighted the 3D solid model import feature in its Max5 CNC, which is based on DXF technology. There is no need to enter feature dimensions, and transform planes are created automatically for five-sided conversational programming.

Sunnen has teamed with Applied Nano Surfaces to offer triboconditioning, a mechanical-chemical process that applies a compound that becomes integrated into metal at a nano level. (It is not a coating.) One application is engine block cylinder sleeves. When combined with honing, it can eliminate the "break-in" process for new engines.

Having a compact footprint and short travels, the Haas UMC 500 five-axis machine is well-suited for five-axis positioning or full contouring of small, complex components.

Machine shops can get better performance from manual knee mills with a CNC retrofit kit like Heidenhain’s Acu-Rite brand offers. The kit includes new ballscrews, drives, control, and scales on X, Y and Z axes. The company says even big OEMs are retrofitting theirs, so it’s not just for small shops.

Available in the United States from Southwestern Industries Inc., Trak Machine Tools’ Prototrak 2OP is a compact VMC that can be used as a second-op machine or a standalone unit. The latest design features a 10,000-rpm spindle.

Chick’s OneLok vise jaw system enables fast jaw changeovers. Once a jaw is inserted, it is secured after a few twists of a T-handle wrench.

This Omax ProtoMax is a compact waterjet machine that can cut a range of materials up to 1-inch thick. It is well-suited for small job shops, engineering classrooms, makerspaces and hobbiest use.

Mass Finishing Inc. (MFI) offers centrifugal barrel finishers used to deburr and polish parts. MFI says a part that might take four hours to finish in a vibratory tumbler can be completed in 20 minutes using its system. The concept is similar to a Ferris wheel, in which parts and media are installed in barrels that rotate as the turret rotates. This motion causes parts and media to contact each other, smoothing part finish.

RELATED CONTENT

-

A Race to the Machined Part (Surface) Finish

To improve component finish as well as engine and gearbox performance for its customers, this racing motorcycle rebuild company uses a super-finishing process for gears and related components which is more commonly used for aerospace and jewelry applications.

-

How Eaton Uses Metal 3D Printing

With the ability to address customer needs faster and iterate parts quickly, this metal 3D printing system is now standard within the workflow for both the engineering and toolroom teams.

-

Will Transmission Manufacturers Turn to Out-Of-Round Turning?

Out-of-round turning can be an efficient alternative to profile milling and grinding for polygon couplings that could replace traditional spline connections in automotive transmissions.

.jpg;width=70;height=70;mode=crop)