Expanding Shopfloor Capability with EDM

DuPage Machine Products chooses to augment its successful multi-spindle and machining business with the installation of an EDM department. Here’s the story.

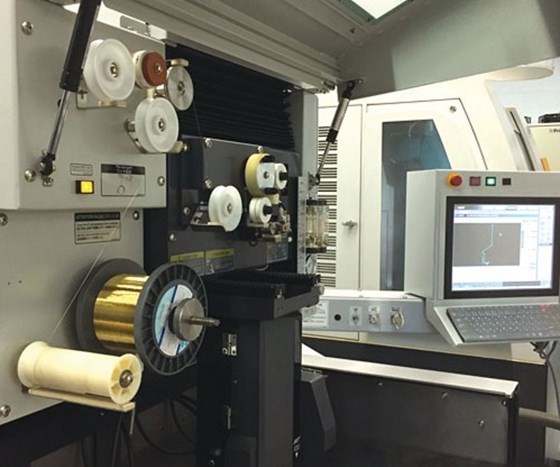

A Mitsubishi MD+Pro III EDM machine is the centerpiece of DuPage’s tool room.

For as long as I can remember, there has been a tension in metalworking manufacturing in regards to vertical integration versus farming out work to others. Making the decision is usually based on factors such as delivery pressure, capital equipment capacity, strength of orders, and in-house skillsets. The decision is also often a dynamic one, which reflects changes in the factors happening on the shop floor.

DuPage Machine Products (Chicago, Illinois) is one such company. It chooses to augment its successful multi-spindle and machining business with the installation of an EDM department.

The EDM department is currently captive and supplies the shop with reliable form tools, which the shop has high demand for to feed its line of multi-spindle machines. The thinking is to build the skills, such as those needed for EDM, in-house with the plan being to offer an additional, value-added service to its customers over time.

It’s a solid template to follow for expanding the shopfloor capability of a shop in order to provide more capability to respond to changing customer demands. The article, “EDM Enables Do-it-Yourself Form Tools,” tells how DuPage made the move to EDM and how it’s working for the company.