Getting Ready for Lights-Out Manufacturing

Lights-out manufacturing has the potential to save money while increasing capacity, but shops need the right equipment and to address potential challenges before implementing it.

#techbrief

Lights-out manufacturing is an approach to manufacturing where no human intervention is required to run a CNC machine shop for a specific duration of time. The machines run automatically with no need for operators or surveillance. The term “lights out” is used metaphorically, as it is much more involved and intricate than just switching off the lights while the machines run.

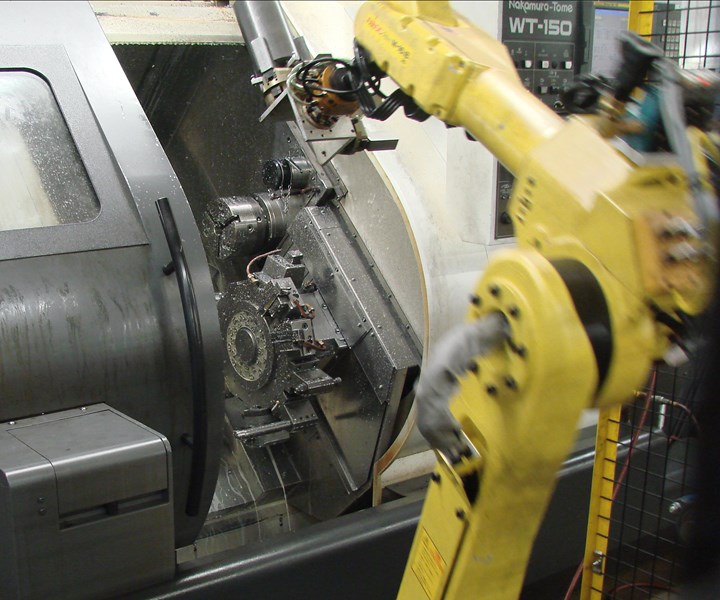

Having a reliable way to load and unload machine tools is essential for lights-out manufacturing. Robotic arms that palletize complete parts are a common solution.

This concept has tremendous potential for capital savings by reducing labor costs. As competition among CNC machine shops grows and clients demand more precise work at minimum cost, going unmanned with lights-out machining can help manufacturers meet these challenges.

With rapid technical advancements, it is possible to implement lights-out manufacturing for both large factories and small-scale machine shops. However, there are many potential concerns shops should address before implementing lights-out manufacturing.

Benefits of Lights-Out

The fundamental force that is driving machine shops to think about lights-out manufacturing is reduced cost. Here are some of the specific savings and additional benefits shops can see as a result of lights-out manufacturing:

- Savings in labor costs. Labor expenses are the principle contributor to variation in costs, and trained personnel are difficult to find. Because lights-out manufacturing requires no human intervention, there is great potential for saving labor costs.

- Increased capacity and productivity. Lights-out manufacturing enables shops to accomplish more work with the same capital because of the additional capabilities of the machines, including extra machining hours. Manufacturers can take on additional work orders and deliver them by adding extra hours of fully automated manufacturing. Shops can allocate simpler components for unattended machining and leave more complex tasks for personnel to handle during the day.

- Energy efficiency. Robotic arms don’t demand an air-conditioned environment. Other auxiliary energy requirements such as lighting and ventilation can also be minimized. Additionally, energy costs less at the night as opposed to during the day.

- Consistency. Automated work can be more consistent than parts made without automation. Deviations in work because of temperature variation can also be reduced, as lights-out manufacturing can be done in constant working conditions.

Technical Aspects of Implementation

Shops can begin lights-out manufacturing without making a huge investment and improve continuously from there. Here are some types of equipment to consider:

Bar feeders are a reliable way to continuously load lathes during unattended machining.

- Workpiece loading and unloading. Lights-out machining requires continuous loaders that can match the pace of the machines. For lathes, bar feeders are reliable loaders. Robotic arms that palletize completed parts in an organized way are also common, as are vacuum unloaders.

- Cutting tools. Ideally, shops should have a system that checks cutting tool inserts for breakage and wear, confirms that the tools are running properly and ensures the position of the tool table. A combination of automatic tool setting (which uses probes to gage the apparatus counterbalances, alter them for wear and check for damage) and load fault capacity (which stops the machine if the shaft stack surpasses a programmed limit, possibly because the apparatus is hitting something) is commonly used. Having an extra cutting tool on standby is always preferable because it enables manufacturing to continue even if the principle cutter breaks.

- Chip and coolant management. There are numerous tasks associated with managing coolants and chips, including filling the coolant repository, ensuring the coolant nozzles are pointed correctly and clearing the machine of chips from earlier jobs. Chip transport needs to be able to handle the amount and type of chips created during production. The transport should effectively channel coolant to prevent fines from polluting the cutting liquid and potentially stopping up coolant carrying nozzles or causing a pump breakdown. Coolant filtration and pressure monitoring are necessities in lights-out manufacturing, as they help improve reliability and durability.

Some observation and information gathering is a crucial early move toward lights-out manufacturing. Setting up notifications for machine alarms is an easy initial step.

- Monitoring and data collection. Some observation and information gathering is a crucial early move toward lights-out manufacturing. Setting up notifications for machine alarms is an easy initial step, and from that point manufacturers can implement camera and machine data collection. Shops can screen the machine table and control board with web cameras, which are available with low light ability.

Challenges of Lights-Out

Lights-out manufacturing is feasible and executable for machine shops, but there are some challenges associated with this strategy:

- Technical barriers. Robots and other auxiliary peripheral devices that enable continuous operation of CNC machines may require technical knowledge and a significant amount of money. Shops should also consider that robots can be limited in flexibility, and robotic systems may need to be specially designed for some automated processes.

- Economy of scale. Designing a lights-out manufacturing process requires complex technical activities, so the volume of work needs to be sufficient to pay back the investment of time and money shops put in to setting it up. Lights-out manufacturing only makes sense if it compensates for setup times and efforts in the long term, so it isn’t well suited to small-scale activities.

- Nature of work. Repetitive, simple work is best for lights-out manufacturing. The process must be designed according to the size of the workpiece, and the weight of the parts should not exceed the capacity of the machines and robotics used.

- Safety and reliability. By principle, there is no operator to address potential equipment malfunctions during lights-out machining. This means that any machines used must be reliable and tested, and the machine tools, peripherals and automation equipment should be designed to minimize possible errors.

Planned preventive maintenance is a necessity for lights-out manufacturing. Sensors can pick up on problems with machinery and react accordingly. A single person approach, where one operator monitors all processes from a remote location and can take effective remedial action in case of emergencies or mishaps, is also fairly common. Some companies offer products with remote monitoring features, which enable users to monitor automated processes with a smartphone or other device.

The Bottom Line

A well-executed lights-out machining program has tremendous potential to improve the way machining gets done, but shops must be willing to make the investment and improve their processes.

CNC Machines | 844-262-6789 | cncmachines.com

About the Author

Curt Doherty

Curt Doherty is the CEO of CNC Machines, a marketplace to directly buy and sell CNC machines.

RELATED CONTENT

-

Automating CNC Lathe Part Loading/Unloading

Read about how you can automate the loading/unloading of your CNC lathes to reduce the labor cost on longer running jobs.

-

Simplifying Machine Load/Unload Automation

Today, lower part volumes and frequent change-over are changing the offerings of some automation integrators. Standard, off-the-shelf components are being engineered to work together in a large variety of applications and, in some cases, are even portable so they can be moved from machine tool to machine tool.

-

10 Smart Steps to Take Toward Recovery

With many manufacturers facing challenges in light of the novel coronavirus pandemic, these 10 steps can help position manufacturers to find success.