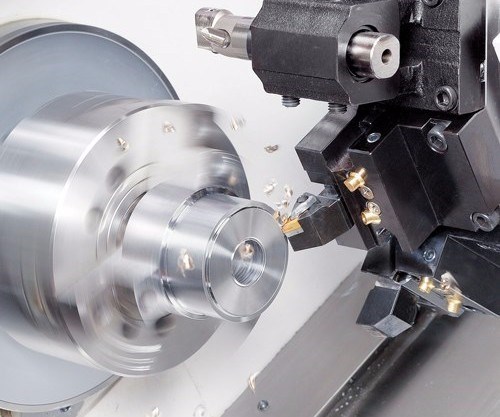

Hard Turning as Cost-Effective Alternative to Grinding

Compared with grinding, hard turning can save countless hours of setup and production time. But a shop should expect a learning curve.

Compared to grinding, hard turning can save a shop countless hours of setup and production time.

Compared to grinding, hard turning can save a shop countless hours of setup and production time. But when hard turning is added a learning curve should be expected, as shops often underestimate their machines’ capabilities or overestimate the complexity of the hard turning process, passing up opportunities that could lead to new business.

Hard turning does have its limitations, such as tooling being more expensive and exposing a shop to difficulties with interrupted cuts. But when applied correctly, such as being knowledgeable of how much heat hard turning generates and the construction of way systems, it can lead to significant savings and new business.

Chris Felix writes more about how hard turning can open doors to new opportunities in PM column, “Increasing Business with Hard Turning.” Read the entire article here.