Let’s Talk About Less Machining Chatter

For some turning work, unwanted harmonics can cause chatter and poor surface finishes. A new CNC software capability can automatically compensate for this.

Harmful harmonic frequencies can cause chatter, especially when turning long, small-diameter workpieces or creating threads in them. The Spindle Harmonics Control feature in Hurco’s version 11 WinMax CNC software can prevent this by automatically varying spindle speed in areas where chatter was present to achieve better surface finishes and tool life.

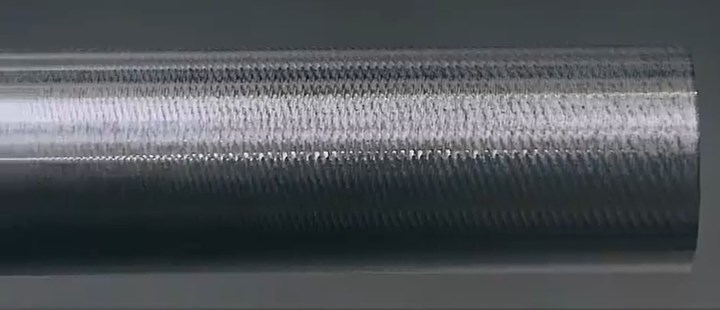

Chatter marks can be left behind when unwanted harmonic frequencies are created during turning operations.

For example, chatter might not be an issue when turning a shaft with a relatively large diameter close to the chuck. However, an operator might notice that it is a problem when turning a smaller diameter further away from the chuck where there’s less rigidity. The Spindle Harmonics Control function can be set to oscillate the programmed spindle speed between 100% and a lower or higher percentage for a certain period of time so as not to introduce the harmonics that cause chatter. This function is activated by an M83 code that is inserted before the problem data block and deactivated with an M84 code that is added after that block. That way, an operator doesn’t have to remain at the machine manually adjusting the feed rate override accordingly. Instead, if chatter is noticed during initial runs of a new job, the function can be added to the program.

RELATED CONTENT

-

Adaptive Machining: The Last Puzzle Piece for Automated Production?

Automatically monitoring and adjusting cutting parameters inside a machine while checking for tool wear is just as important to establishing a reliable lights-out machining process as having a robot outside the machine.

-

Adding 5-Axis Capability to a 3-Axis CNC Mill

This attachment provides shops using thee-axis machining centers the option of on-demand four- and five-axis machining.

-

Compact Second-Op CNC Mill Gets Makeover

New control and programming capabilities make this small VMC well suited for second-op work or use as a standalone production milling machine.