Metrology Looks at Industry 4.0

Every shop makes parts, but making them correctly is the role of measurement and inspection.

#Industry40

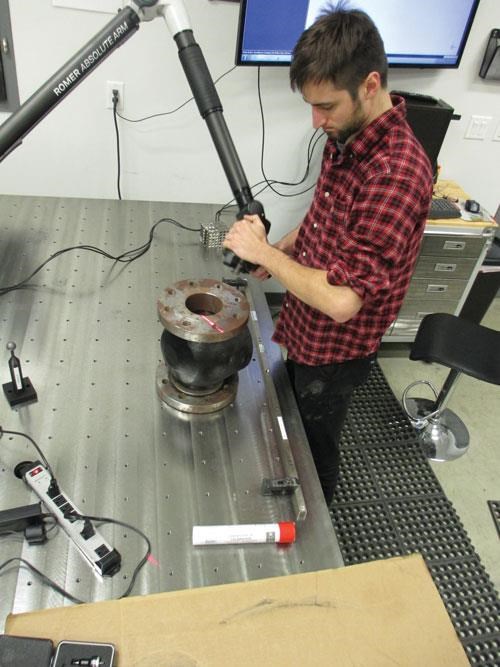

With only a portable CMM arm and laptop on the shop floor, machine parts can be scanned with the data points sent upstream for instant analysis, comparison with the CAD data, the CAM program, comparable machines in the shop producing the same or similar parts and other action items in an information stream.

In our February issue, we took a look at Industry 4.0, also called the Industrial Internet of Things (IIoT) from the perspective of metrology. This article, contributed by Steve Young and Dean Solberg, co-owners of Exact Metrology, examines how the data that is collected on the shop floor can be used by company management on the top floor to make the right decisions for the company’s success.

Every shop makes parts, but making them correctly is the role of measurement and inspection. Yes, it’s a cost, but it is also really a benchmark of how well or poorly the manufacturing process is being implemented. Scrap costs money too, and scrap in the customer’s hands can be even more costly.

The measurement tools available to shops today are remarkable in their sophistication and ease of use. Collecting “big data” from these devices can help shops make the best decisions on how they manufacture and apply those decisions to efficiency and productivity on the shop floor.

Click here to read the full article, "Industry 4.0 Through Metrology's Eyes."

RELATED CONTENT

-

Industry 4.0 Careers of the Future

Know a young person considering a career pathway? Encourage him or her to consider these careers.

-

Manufacturing Data Collection and Management Transforms Swiss Shop

A New Hampshire high-volume precision solutions manufacturer and an innovative software solutions provider have collaborated in upgrading the shop’s data collection and organization methods, maximizing output and competitiveness.

-

Robotic Automation's Challenges, Solutions and Benefits

This article looks at considerations for implementing robotic automation.