Paul Horn Facility Showcases its Expertise

Paul Horn GmbH’s facility in Tübingen, Germany, is impressive not only because of its cleanliness, but the size of the campus and the company’s fast growth from year to year.

Upon stepping foot on Paul Horn GmbH’s factory floor for the first time, I knew it was a special company. I could see my reflection in the shiny, white finish, and I am pretty sure that I uttered aloud, “Wow, I could eat strudel off the floors in here!”

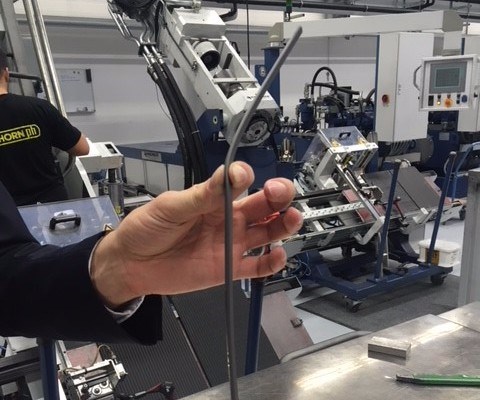

Horn’s facility in Tübingen, Germany, is impressive not only because of its cleanliness, but the size of the campus and the company’s fast growth from year to year. Over the past two years, Horn doubled its production floor with an investment of 70 million Euros. Horn has 75 milling centers, turning machines and other machinery for in-house production of all its toolholders and additional equipment.

The company has a product range that includes more than 120,000 variants with a ratio of standard and special tools that is around 50/50. They produce 9 million inserts annually in lot sizes of 100 pieces on average. The company’s managing director, Lothar Horn, humbly describes the company as a small, medium-sized producer.

My visit to the Horn facility consisted of a walking tour that took about two-and-a-half hours led by Christian Thiele, corporate communications and marketing manager. He walked our small group through each building and explained, in detail, the process of creating cutting tool inserts using carbide and injection molding all the way to the final step of the coating process.

At the end of the tour, I saw the apprenticeship training center, which is one of the outstanding areas of the company. Sixty apprentices are currently employed through the company’s apprenticeship program, and six students participate in the program as well. Most apprentices eventually end up working for the company. The “secure line of supply” provides skilled workers for Horn’s future.