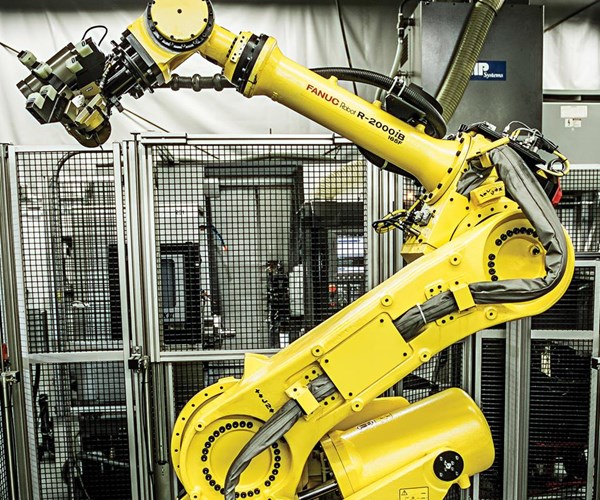

Robotic Efficiency

Shops implement automation for different reasons. Read about one that used robotics to improve production by almost 90 percent while effectively redistributing labor on the shop floor.

Shop owners have varying reasons for pursuing automation on their shop floors. Sometimes they’re after better machine usage and higher production capacity. Others may be compensating for a shortage of labor. Still others may have a need for flexibility in adjusting to changing production requirements. One North Carolina shop incorporated robotic automation as a progressive move to remain competitive and improve workflow.

Read “Reducing Production Times with Robotic Automation” to learn how Northeast Tool improved production by almost 90 percent. The company condensed the functions of three CNC lathes, two milling operations, polishing, washing and inspections after each operation into a single cell consisting of one robot and two lathes. Instead of requiring time from 15 people, the new setup is now manned by a single operator.

RELATED CONTENT

-

Simplifying Machine Load/Unload Automation

Today, lower part volumes and frequent change-over are changing the offerings of some automation integrators. Standard, off-the-shelf components are being engineered to work together in a large variety of applications and, in some cases, are even portable so they can be moved from machine tool to machine tool.

-

What Is The Best Bar Feed System For Production Turning?

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.

-

Choosing an Automatic Bar Feeder

The bar feeder is the most common form of automation for turning operations. Selecting the right one requires consideration of the applications for which it will be used.

.png;maxWidth=970;quality=90)