The Next Step for Coating Metal Parts

Selecting the right finishing applicator can be as big of a challenge as producing the part. Here are the key considerations to ensure a quality finish and reasonable delivery.

#columns

As the industrial world continues to evolve, the need for different coatings of metal surfaces changes as well. The challenges raised by the final owner of a given part continue to become more complex. Several matters need to be considered when choosing the appropriate finishing applicator.

Just as there are different levels of capabilities among metalworking and metal fabricating facilities, there are also many different levels of applicators in the world of coating. Choosing the correct finisher is an important and often overlooked step in the final phase of manufacturing. The following considerations are paramount in getting the job done right.

These brake calipers feature hybrid coatings—a zinc/nickel alloy coating, followed by passivate, followed by paint.

Logistics—Logistics can play a significant role. In some instances, the location of the finisher is critical because freight influences the final cost of the finished good. Some applicators have their own fleet of trucks.

Organic versus inorganic—The requirement for organic finishes (paint) or inorganic finishes can have an impact on the best suited applicator for the job. Selecting a finisher that meets the quality requirements, as well as the specification of the final OEM is a consideration. The size of the parts to be processed can also be a limiting factor. Is the paint booth/tank/electrocoat (ecoat) tank able to accommodate the part size? Some OEMs specify specific process chemistry, and not all applicators will have those finishes or chemistries. Thoroughly examine the capabilities of the finisher before committing to the job.

Layers—In today’s world, often one coating layer is not enough to meet the decorative or corrosion criteria of the end user. This is where things become more complicated. The finish could be zinc or zinc/nickel electroplating, followed by a trivalent RoHs-compliant passivate, followed by an inorganic finish such as ecoat, powdercoat, wet paint, adhesives (rubber bonding) or zinc flake. All of these matrix coatings offer an entirely different perspective and performance characteristic that is not available from a single layer of a given coating. Looking for an applicator that can provide both organic and inorganic finishes is a key. An applicator whose chemical supplier has all the finishes required will eliminate finger pointing if coating issues arise.

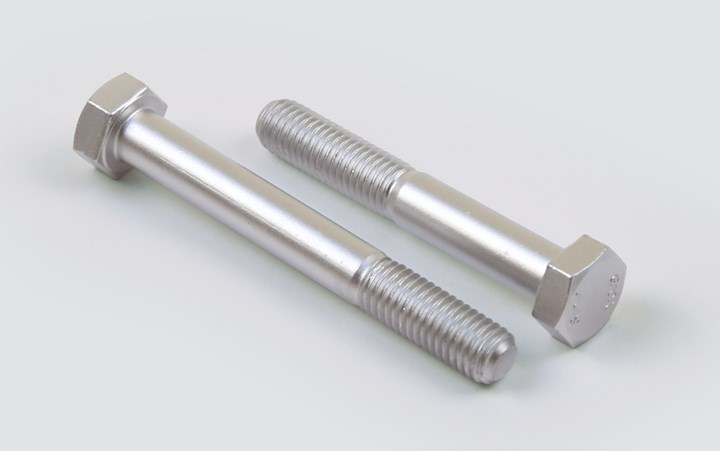

These bolts are finished with a zinc flake dip spin coating.

Thickness—Consideration of final coating thickness is also a critical element when choosing an applicator. In the business of dip/spin zinc flake coatings, appropriate equipment is needed to minimize head or thread fill (for fasteners) or tapped hole fill. Not all applicators have this application equipment available.

Quality—Does the applicator have a quality system in place? Accreditations such as National Aerospace and Defense Contractors Accreditation Program (Nadcap), CQI (Chartered Quality Institute) or others may provide the necessary quality level. Not all applicators have advanced quality systems.

Part Mating—If the part needs to mate with another part from a different source, questions could arise regarding decorative “color matching” or “galvanic corrosion concerns.”

Testing—The applicator should have access to a technical center that can apply various coating types for evaluation as well as run the required corrosion tests.

Tooling—Does the applicator have all the tooling needed, or will new, special tooling be necessary? Some applicators make their own fixtures, which can facilitate better production times.

Coatings Supplier—In some instances, the company supplying the coating materials to the applicator may have significant resources at its disposal, including:

- Technical centers with large part process capabilities in house to provide production-like sample runs of various coatings

- Metallurgical and analytical laboratories that can look at surface conditions as well as process analytics, both aiding in defining a process and identifying root causes of defects

- Multiple coating capabilities, which can offer the OEM or Tier the opportunity to explore all types of coatings or, in some cases, coatings that consist of both organic and inorganic materials

- A catalog of already proven finishes of both single-coating and multi-coating outcomes, which can often supply “off-the-shelf” results aiding in fast design of the final finish

- Global services, allowing for cut and paste of the desired finish(es) applied elsewhere in the world for uniform supply chain results

When faced with the challenge of defining a coating type as well as an applicator network that meets the needs for the production process, folding in a coatings manufacturer can often shorten the cycle to market entry.

About the Author

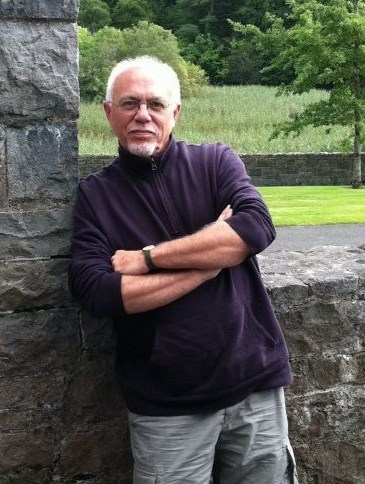

Steve Kocka is general metal finishing business director for North America at Atotech USA LLC. Prior to his 20 years at Atotech, he was involved with research, development and manufacturing of membrane keyboards as an entry point into electroplating. Involved in the industry since 1974, he has also worked for three distributors of chemistry and equipment for surface finishing.

RELATED CONTENT

-

The Basics of Cleaning with a Parts Washer

Better Engineering answers the question of “What do I need to know about an aqueous parts washer and its process?”

-

Good Bonding and Coating with Contact Angle Measurements

Darren Williams answers common questions about using a contact angle measurement to determine part cleanliness. Using water to test cleanliness reveals the effectiveness of a cleaning process.

-

7 Muda Wastes Every Machine Shop Should Eliminate

Applying lean manufacturing concepts, the Flexible Production method can help put a stop to production wastes, specifically for those who use transfer machines or machining centers.