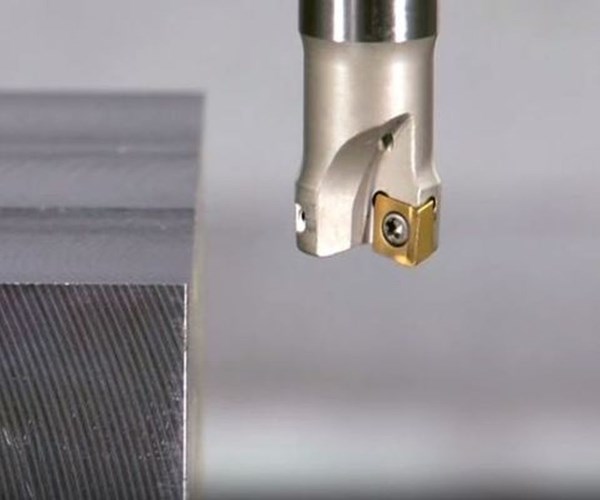

Video: Micro Insert for Live Tooling on Swiss Lathes

This easy-loading 5-mm I.C. micro insert is designed to run at maximum feed rates and is equipped with fine-pitched densities for high-productivity machining.

The DiPos Tetra 5-mm micro insert from Ingersoll Machine Tools is an ideal companion for live turning applications on Swiss-type lathes. Double dovetail pockets allow for easy insert indexing—clamps can be inserted in the pocket while affixing the screw, in fact. Double dovetail pocket along with strong M2.0 insert screw promotes ultra-stable insert mounting, particularly when running at high feed rates. Double positive insert geometry offers 0.18-inch axial depth of cut capability with two indexes. Its 0.03-inch integrated wiper flats produce surface finishes as good as Ra 32, and it has a 0.50-2.00-inch cutter diameter range. According to the company, this multi-functional tool does everything—it ramps, plunges, and interpolates, and it does so in an aggressive fashion. Watch the video to see it in action. Learn more about other micro-machining tooling in this article from Production Machining.

RELATED CONTENT

-

4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.