More Productive than CNC Swiss-Type Lathes

More than 40 percent of the parts cut on CNC Swiss-type lathes can be made on CNC multi-spindle lathes at a fraction of the cost. While more expensive, CNC multi-spindle machines can turn and mill parts up to six times faster and from standard barstock.

By INDEX Traub

With today’s market conditions, many American manufacturers are fortunate to be facing the issue of how to most effectively grow their operations. If you can easily expand your facility with access to readily available skilled labor, the solution might seem straightforward. Simply buy more machines, hire more people and win more business. Of course, the impact on your profitability will be minimal, as the relationship between your income and expenses will remain somewhat linear. A different approach is required to achieve substantial growth in the face of constraints on your floor space or talent pool.

Over the past decade, much has been written about the paths a shop can take to significantly improve throughput and productivity. Automation, for example, stretches labor further and can keep you running 24/7 without adding shifts. Optimizing cutting processes can also ensure that your machines are operating at their full potential. Workflow analysis and lean implementation eliminate costly waste from your facility. Equally impactful, yet less frequently discussed, is the importance of matching the parts you make to the best possible machines to produce them. For owners of Swiss-type turning centers, this includes seriously evaluating the potential benefits of investing in one or more CNC multi-spindle lathes.

This animation shows how an INDEX multispindle CNC turning machine works. Capable of high production, high precision, and major cycle time savings, the

multis make better parts faster and at lower cost per piece.

Matching the Right Parts to the Right Machines

Most shops running Swiss-type turning centers apply them to many parts that could be better produced elsewhere. Recent estimates place more than 40% of the parts currently being cut on Swiss-type machines into this category. This creates tremendous opportunity for improvements to both throughput and cost.

Swiss turning operations require high-quality ground bar stock to ensure a proper fit through the guide bushing. This leads to higher cost when compared to using standard bar stock with a fixed headstock machine. Additionally, setting up Swiss-type operations can be time consuming due to the guide bushing, influences of the incoming material on processes and other considerations. Lastly, certain types of parts commonly run on Swiss-type machines can be produced four to six times faster with the right multi-spindle solution. This last factor offers the largest potential for cycle time and cost reductions.

Jake Grainger, owner of Alpha Grainger, says that multi-spindle machines have “given me a way to be more productive than anyone else – more accurately, faster, more reliably.” .Read his story

The impact of being able to produce a whole category of parts up to six times faster is hard to overstate. For a mid-size shop running 30 Swiss-type machines under typical circumstances, 12 of those could be replaced with 2 or 3 multi-spindles. This frees up significant floor space and labor hours, as well as simplifies unmanned production for lights-out shifts. For shops approaching space constraints, they gain immediate growth capacity without the cost of expanding their facility or moving to a new one. Similarly, shops butting up against the skilled labor shortage instantly arm their existing operators to become far more productive.

Beyond the more transformational aspects of the technology, multi-spindles provide immediate cost reductions. Due to their incredible capacity, they significantly reduce the portion of the cost per piece determined by the machine payments, despite representing a higher level of investment. The three following examples are based on cost analyses of real-world parts and demonstrate the types of gains that can be achieved by moving certain work from Swiss-type machines to multi-spindle machines.

Case 1 – Stainless Steel Machinery Screw

This common screw component used by a small machinery provider is 0.669" (17 mm) long and machined from Ø0.472" (12 mm) stainless steel bar stock. It requires turning, sawing and single-point threading operations. Switching it to a multi-spindle machine reduced cycle time by 82.4% and cost per piece by 25%.

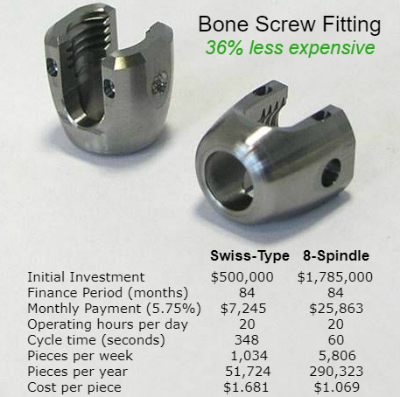

Case 2 – Titanium Bone Screw Fitting

Machined from Ø0.591" (15 mm) titanium bar stock, this bone screw fitting requires turning, drilling, thread milling and milling operations. The part measures 0.571" (14.5 mm) in length, and moving it to an 8-spindle machine resulted in a 36.4% decrease in cost per piece.

Case 3 – Stainless Steel Hydraulic/ Pneumatic Part

This small part used in hydraulic and pneumatic applications measures just 0.236" (6 mm) long and is produced from Ø0.551" (14 mm) X46Cr13 bar stock. Requiring turning and drilling operations, its cost per piece was reduced by 27.7% by switching it to an 8-spindle machine.

These examples capture the benefit multi-spindles offer relating directly to cost per piece, but note that each of them also demonstrates an application where a single multi-spindle machine is doing the work of nearly six traditional Swiss-type machines. The advantages of that productivity will vary depending on shop conditions, and may well outpace the more straightforward cost reduction in many scenarios.

The Case for Multi-Spindles

The preceding examples and countless similar parts have historically been run on Swiss-type machines for two basic reasons: small part size and available machine capacity. As previously stated, this has led to an estimated 40% of the parts being machined on Swiss-type machines actually being better suited for another approach. If a part is less than 1.25" in diameter with a length-to-diameter ratio of at least 4:1, there is a strong probability that a Swiss-type machine is the best option. For small parts that fail to meet those criteria, a multi-spindle machine is likely to provide increased throughput and cost performance.

Several additional factors merit consideration when evaluating whether a multi-spindle machine makes sense for your operations. Traditionally, many have viewed these machines as requiring long setup times and complicated programs, limiting their suitability to jobs with large lot sizes. Current technology has largely eradicated those concerns. With quick-change tooling, offline presetting and adequate planning, modern multi-spindles can be changed over within an hour or two. They have also become extremely simple to program. In short, many companies experience cost benefits on lot sizes as low as 2,500 pieces.

As might be expected, price is the most commonly cited reason companies stop short of seriously considering adding one or more multi-spindle machines to their mix. But for the right parts, though multi-spindle machines do represent a high level of investment, they are considerably less expensive than alternative modes of production when evaluating return on investment rather than net outlay.

Download White Paper on Justifying Technology for a precision machine shop.

Determining the true cost of the machine requires identifying the model best suited to your operations and analysis of current and expected workflow.

Additionally, the time is ripe for undertaking investments to improve your capabilities, capacity and flexibility. Forecasts predict continued health within manufacturing and a wide variety of financing options are currently at your disposal.

A significant number of shops are also taking advantage of a range of leasing options, allowing them to mitigate long-term risk while improving their current efficiency and profitability. With today’s relatively low interest rates, a lease provides a cost effective opportunity to begin the transition from Swiss-type machines to multi-spindles, comfortable in the knowledge that the machine can be returned at the end of the lease if market conditions change.

Creating Your Best Possible Future

Whether you are experiencing significant growth or simply want to maximize the cost effectiveness of your operations, if you currently run a significant amount of work across Swiss-type machines, multi-spindle options deserve your consideration. To start, look at the parts you are currently producing. Are you in line with the rest of the industry, with 40% of them not requiring a sliding headstock machine? Or maybe you are at 25%? Or 50%? Once you have started to quantify the amount of work better suited to a multi-spindle machine, you can begin to develop a realistic picture of the potential cost benefits within your grasp.

Interested in the impact of multi-spindle technology on throughput and profitability? Contact the industry experts at INDEX Corp. at info@indextraub.com.