XING Dressing Keeps Grinding Wheels True

Grinding and dressing wheels can wear down over time, so for tapered or V-shaped diamond grinding wheels that handle carbide inserts, Haas Multigrind LLC came up with the XING dressing.

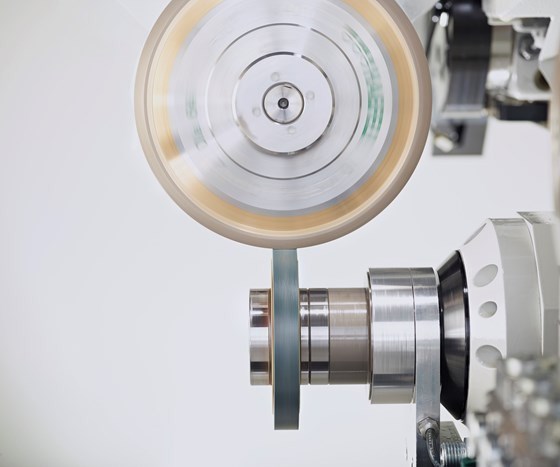

XING-dressing a tapered diamond grinding wheel, which is positioned at a 90-degree angle to the dresser wheel.

Grinding and dressing wheels can wear down over time, as shops across several industries have experienced. Profile inserts, in particular, can wear down grinding wheels. Becoming out of true is a problem for manufacturers as misshapen grinding wheels will result in negative effects both on quality and productivity.

For tapered or V-shaped diamond grinding wheels that handle carbide inserts, Haas Multigrind LLC has come up with a new dressing technique. The process is called XING (short for “cross”) dressing, with a silicon carbide or corundum wheel sharpening the abrasive particles on a grinding wheel. With this technique the dressing wheel is also positioned at a 90-degree angle to create a perfect radius.

In “Dressing Technique for Truing Up Diamond Grinding Wheels” the benefits of XING dressing are discussed, including how the process is carried out inside the grinding machine, eliminating the need for unclamping and re-chucking of the grinding wheel. For more on how to reestablish a precise geometry and create optimal grinding wheel topography with the regular and proper dressing of grinding wheels, read the article here.