Applying Technology to Save Lives

Given the number of tragic news stories we’ve already heard this early in the year, I thought I’d turn the tables and revisit one of the most incredible positive stories of 2010. On October 13, the last of the 33 Chilean miners who were trapped 2,067 feet underground for more than 2 months, was rescued.

Given the number of tragic news stories we’ve already heard this early in the year, I thought I’d turn the tables and revisit one of the most incredible positive stories of 2010. On October 13, the last of the 33 Chilean miners who were trapped 2,067 feet underground for more than 2 months, was rescued. It was a painstaking and treacherous process to bring each one to safety, but it was successful thanks to the efforts of many and the technological advances in drilling equipment and search and rescue operations.

One company, Center Rock Inc., of Berlin, Pa., was responsible for production of the highly advanced, low-profile Hole Opener drills that helped shorten the rescue by 2.5 months from the original time estimate. The drills use highly compressed air (instead of fluids) to drive drill bits and clear rock fragments. They use multiple pneumatic hammers, each steadily pounding a drill bit to crush rock as the drill rotates. The compressed air also circulates to blow rock flakes and dust upward, away from the bits.

Featured Content

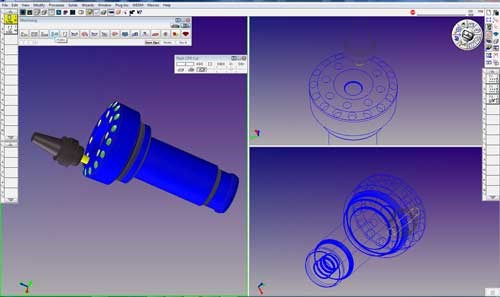

In this rescue operation, Center Rock used three drill sizes. Machined components for the drills include the flange and receivers at the top, the flat plates, the chucks for the hammers and a long, serrated pilot. During production of the drills, in addition to turning operations, areas of each bit may require flat, contour, radial or axial milling, and each bit may require various holes at different angles. These features, combined, lend themselves well to multitask machining.

Center Rock uses GibbsCAM to program the line-up of machine tools, which include three Doosan two-axis lathes, two Mazak horizontal machining centers, and two Doosan multi-tasking machines. The company has been using GibbsCAM mill-turn and three-axis milling modules since 2005 and GibbsCAM rotary milling and advanced MTM modules since 2006. The integrated modules open SolidWorks CAD models directly so that programmers can use and manipulate engineers’ solid-model geometry to program their CNCs.

Because all operations are integrated, the programmer can stay within the same user interface without having to exit an active module to initiate another. All operations—turning, milling, drilling and non-cutting motion such as tool changes, turret motion and transfers between spindles—are executed within the same interface. The software also provides automated and interactive ways to insert syncs (wait codes) and displays flows for each tool group side by side, simplifying toolpath optimization for the programmer.

Just as Center Rock was able to use its technology and expertise to greatly reduce the time needed to rescue the miners, GibbsCAM helps the company’s programmers and machinists speed production of drills and drill bits every day.

RELATED CONTENT

-

Why Using Pirated Software is Riskier Than Ever

Machine shops and manufacturers that use pirated software risk losing much more – both directly and indirectly.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

-

Optimizing B Axis on Gang Tool-Based Swiss Machines

This technological innovation has been increasing in popularity as well as multitasking sophistication.