Multi-Spindles Bring Flexibility to Automotive Supplier

To remain among the top players in a highly competitive market requires innovative minds and efficient, flexible production equipment. This Germany-based automotive supplier possesses both and supports its extraordinary growth with a growing number of CNC multi-spindles.

Wagner Fahrzeugteile is a rapidly growing automotive supplier, who manufactures around 60 million parts per year including turned parts and components such as oil jet nozzles, hydraulic valves and special assemblies in steel, stainless and alloys.

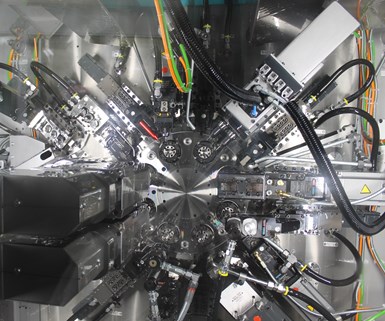

Six brand new multi-spindle automatic lathes—three Index MS16 and three Index MS22-8—fill a quarter of the otherwise empty brand-new production hall at Wagner Fahrzeugteile in Fulda, Germany. What at a first glance looks like a start-up is in fact the latest of many production expansions of this rapidly growing automotive supplier, that specializes in turned parts and components such as oil jet nozzles, hydraulic valves and special assemblies in steel, stainless and alloys.

Running an impressive total of 51 multi-spindles, the company ordered another eight multis from Index in 2017 and has constantly been expanding its machine park with five to seven single and multi-spindle lathes per year since installing the first multi-spindle Index MS 32 in 2005.

Featured Content

According to Rainer Bott, head of Wagner’s turning shop that employs 90 people and is the company’s fastest growing division, this phenomenal growth is a result of Wagner rising to the challenges the automotive industry is constantly facing. His secret to success is simple: “We are the fastest,” he says and adds that while the German automotive industry is on course for further growth after it produced a record of 15.1 million passenger cars in 2015, Wagner’s rapid growth is an exception and is a result of several factors, including a management team that has constantly been reinventing itself since its inception.

When Richard Luck and Ludwig Wagner formed “Luck & Wagner” in 1919 in Eastern Germany, it was with the intent of becoming a bicycle component manufacturer (pedals and hubs). But after the company’s production equipment was disassembled by Russian soldiers in 1945, Ludwig and Joachim Wagner reestablished Wagner & Co. in Western Germany (Fulda), and started to transform the business to become a supplier for the automotive industry in 1963.

Managing Director Dr. Stephan Wagner, who took over the company in 1985, knew that five things would be most important to be competitive as an automotive supplier: on-time delivery, quality, concentration on core competencies, high flexibility and qualified staff. In addition, investment in the right equipment is another prerequisite for success. As a result, the company invested in its first Index GS30 automatic lathe in 1989.

The installation of Wagner’s first multi-spindle automatic lathe in 1999 was the kick-starter for the company’s unprecedented growth. Today, Wagner manufactures about 60 million parts per year and exclusively runs CNC machines, as cam-controlled machines are not flexible enough in terms of setup times if the company has to quickly react to changing or additional orders. Regular setup times for parts which have been run before are between four and six hours on the Index CNC multis, Mr. Bott says; impossible with cam-driven machines, which need at least two shifts for a new setup.

Quickly Adapting to Changing Requirements

“Flexibility is key, and our lean organization and our capability to quickly

Wagner runs more than 50 Index CNC multi-spindles, which provide for the flexibility needed to remain competitive.

adapt to new, different or changing requirements is what differentiates us from the competition,” Mr. Bott says. “Moreover, we have a very strong team of toolmakers and in-house production capabilities, including robotic brazing, bending, stamping and thread rolling machines.”

The demand for fast and simple setups as well as increasing part complexity, high demands on surface finish and tighter tolerances soon led to the decision to invest in eight-spindle machines. As a result, Wagner took delivery of its first CNC eight-spindle machine in 2011. Today, the turning shop has a total of eleven eight-spindle Index MS22-8 multis, which offer Wagner the flexibility it needs to comply with ever changing customer demands.

“Our capacity utilization is at 99 percent, and when we purchased our first MS22-8, we ran it in double four-spindle mode as two machines working within one cabinet on a single base,” Mr. Bott says. “We then realized that we could reduce our bottlenecks in production, which were parts with backworking where several operations were necessary to finish the part with the subspindle.”

The MS22-8 features two subspindles that can work simultaneously on the workpiece with up to six tools. “If you decide for double rear-end machining, you have six main spindle positions available for front machining and two subspindle positions for simultaneous backworking. When the first six front work operations are completed, both subspindles grab a part each from positions 7 and 8 and have two part cycle times available to finish the part."

Eight Spindles to Reduce Cycle Times

The MS22-8 can be operated as an eight-spindle machine, as a double four-spindle machine or as a machine with double rear-end capability. As a result of double four-spindle machining, two finished parts are produced by the machine per work cycle.

The competitive advantage is enormous, and Mr. Bott knows that the investments will pay off. One example is a mass-produced screw, which requires extensive rear-end machining (see photo). Switching production from the company’s six-spindle multi MS 22-6 to the eight-spindle machine saved a whopping eight seconds in cycle time per part (from 32 seconds to 24 seconds). Meanwhile, the part is running on four, eight-spindle machines for three shifts, with considerable savings. To accomplish internal machining, each MS22-8 is paired with an MS16 multi-spindle lathe.

“Another benefit for us is the variable use of tool carriers for internal and external machining, transverse machining with driven tools as well as numerous possibilities using driven tools in conjunction with C and Y axes. Moreover, all standard toolholders and toolholder system interfaces can be used with a range of popular adapters,” Mr. Bott says. “The front-opening design adds to the machines’ flexibility as the operator has excellent accessibility during setup and tooling.”

Despite the machines’ productivity and flexibility, Wagner has to find skilled operators, which can be a challenge, Mr. Bott says. Multi-spindles are regarded as the "crème de la crème" of screw machines and seem to have an intimidating impact on many people, be it for the impressive technology or the price tag. However, running the latest machines also helps to find motivated staff members who are keen to work with new, clean and high-tech machines, Mr. Bott says.

These will be constantly complemented by even more multis, and since Index has released the MS22-8’s big brother—the MS40C-8—which offers productivity for bigger parts of more than 40-mm bar diameter, Mr. Bott is keen to add it to the company’s already impressive array of CNC equipment. “We have a growing need to machine bigger parts and have recently invested in a six-spindle MS40,” he says. “But we don’t have the work for an MS40C-8 yet.”

This investment will have to wait, but in view of Wagner’s unabated growth, it might not be for long.

RELATED CONTENT

-

Large Threading with Single Spindle

Oilfield pipes require large, quality threads. This Texas shop is getting the performance it needs from two recently implemented big bore lathes.

-

Burr-Free Micro Thread Whirling

Threading is usually the last operation when machining components, which is why the process needs to be reliable and highly precise. DC Swiss has developed an internal thread whirler, which leaves micro threads burr-free, even in demanding, hard-to-machine materials.

-

An Unconventional Approach to Multi-Spindle Production

This shop went with its gut, pushing back on the suppliers who said, "You're making a mistake." It's creative use of multi-spindle technology for small lot sizes is no mistake.