Allied Machine Offers High-Penetration Drill System

Appears in Print as: 'Drilling System Offer High Penetration Rates'

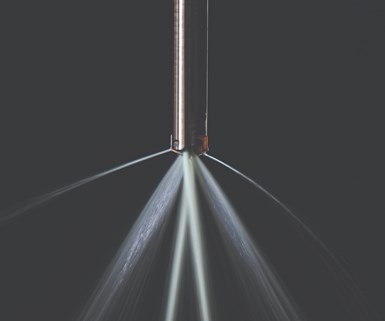

T-A Pro drill designed to extend tool life, create consistent quality holes and provide better chip evacuation.

Edited by Angela Osborne

Allied Machine and Engineering’s T-A Pro drilling system combines material-specific insert geometries, redesigned drill body and proprietary coolant-through system for high-penetration drilling. According to the company, this enables penetration rates which run at speeds nearly 30% faster than other high-performance drills.

The company says that the coolant outlets are designed to direct maximum flow to the cutting edge, providing quick heat extraction where it is most critical, even at significantly higher speeds. Material-specific insert geometries are designed for effective chip formation, while the drill body incorporates straight flutes redesigned for maximum coolant flow and high rigidity. These design elements combine to extend tool life, create consistent quality holes and provide good chip evacuation.

The T-A Pro drilling system is available in diameters ranging from 0.4370" to 1.882" (11.1mm – 47.80mm) and is said to be well-suited for holes ranging in stub, 3×D, 5×D, 7×D, 10×D, 12×D and 15×D depths. The drill comes in both imperial and metric shanks, with flat and cylindrical variants. The initial carbide insert geometries will work with steel (P) with AM300 coating; cast iron (K) with TiAlN coating; and nonferrous (N) with TiCN coating.

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Calculating Surface Footage and RPM for Optimum Tool Life

Tech Brief: Calculating Surface Footage and RPM for Optimum Tool Life

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.