Automated Enshu VMC Eliminates Idle Time

Appears in Print as: 'VMC with Automated Loader Eliminates Idle Time'

The part load/unload mechanism is equipped with twin arms for efficient part handling and zero idle time.

Edited by Angela Osborne

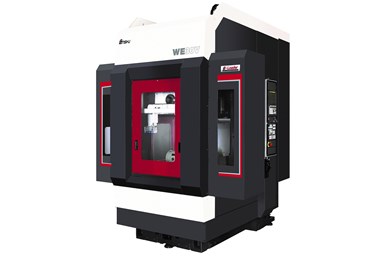

Enshu WE30V machining center

Enshu USA’s WE30V vertical machining center (VMC) comes with an integrated e-loader, which is a built-in automatic part transfer device that is said to provide distinct advantages over the typical external robot, cobot or gantry solution. The WE30V e-loader is a self-contained solution that offers space savings, cost effectiveness and ease of operation, the company says.

The rack and pinion driven e-loader uses a pneumatically actuated, tapered drive pin to engage and drive the part loader along the X-axis motion of the VMC. Located to the right and left of the full X-axis stroke are pick-and-place platforms for part transfer to other machines. The part load/unload mechanism is equipped with twin arms for efficient part handling and minimal idle time. The end-of-arm tooling can be custom designed for applications and has a maximum part weight capacity per arm of 22 lbs.

The WE30V is a BT30 taper VMC with a 12,000-rpm, 7.5-hp direct-drive spindle with rapid traverse rates of 1,968 ipm and a 21-tool ATC magazine. The table size is 25.6" × 15.7" with a weight capacity of 771 lbs. The machine features a FANUC 0iMF control and has been designed with a 200-mm column riser to eliminate any tooling interference that is typically encountered when retrofitting a trunnion-style, five-axis table.

The WE30V e-loader was designed for high-volume, low-mix production environments. Applications include firearms components, medical components and manifold-like workpieces found in automotive and hydraulic/pneumatic industries.

RELATED CONTENT

-

Manufacturing Knowledge is Power

The Knowledge Centers with video produced by brands such as Production Machining on the IMTS spark online platform take deep dives into technology and trends related to various CNC machining and manufacturing topics.

-

Unattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

-

Get 5-Axis Machining on a 3-Axis VMC

Machine shops want and need to eliminate steps in the manufacturing process. Adding four- or five-axis capability to an existing three-axis VMC is a practical way to achieve five-sided machining using a single setup.

.jpg;maxWidth=970;quality=90)