Company Expands Horizontal Travel on Optical Comparator

Appears in Print as: 'Company Expands Horizontal Travel on Optical Comparator'

L.S. Starrett expands horizontal X-axis travel on the HB400 benchtop optical comparator from 12" to 16" to measure large parts on its workstage.

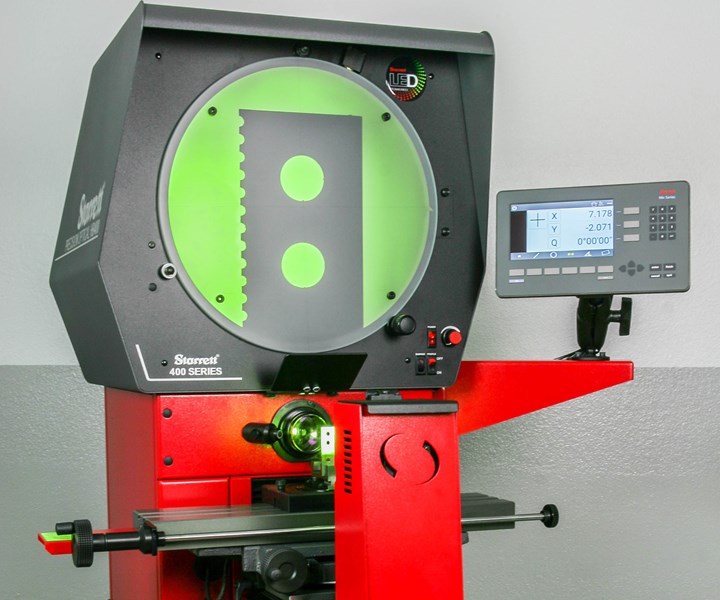

L.S. Starrett has expanded the horizontal X-axis travel on the HB400 benchtop optical comparator from 12" to 16" (300 mm to 400 mm), providing users the versatility to measure large parts on its workstage.

The comparator features a 16" (400-mm) diameter viewing screen, a 16" (400-mm) horizontal travel, a 6" (150-mm) Y vertical travel, a 2" (50-mm) focus travel and a 110 lb. (49.9 kg) workstage load capacity. The HB400 also has all-metal construction with a hard-anodized stage tooling plate, LED profile and surface lighting rated to 50,000 hours, touchscreen operation and a linear encoder glass scale on both X and Y axes. Also includes a digital protractor for angle measurement of 1-ft. resolution via Q-axis readout.

The HB400 has a single, bayonet-style lens mounting system that accepts a choice of six fixed interchangeable lenses, as well as OV2 Zoom or TOV2 fixed telecentric magnification video camera systems. Available with MetLogix M1 tablet, M2 or M3 measuring software (when using OV2 and TOV2) PC or digital readout systems.

RELATED CONTENT

-

Measure 3D Parts Without Losing Time

This high-speed metrology and inspection system is said to process complex geometries faster than traditional inspection methods.

-

How to Choose and Use Styli

The variety of probe applications on machine tools, CMMs, comparative gages and portable arms makes correct selection of styli usage essential for efficient, reliable and accurate measurement. Here are some key points that can be helpful in choosing the best measurement solution.

-

Determine Passivation of Stainless

Properly cleaned stainless steel is naturally protected from corrosion by a thin, passive film. But this passive layer can be removed or scratched. A passivation meter measures the surface potential under controlled conditions.