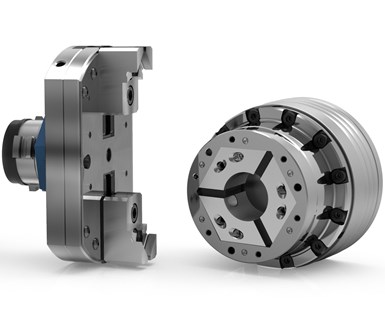

Hainbuch 2-Jaw Module Adapts to Clamp Cubic Parts

Appears in Print as: 'Workholding Module Adapts to Clamp Cubic Parts'

The 2-Jaw module delivers small alternative to large centric vice.

Edited by Angela Osborne

For cubic parts that are positioned centrically on machining centers and milling machines, Hainbuch’s 2-Jaw module adapter enables manufacturers to change over from clamping round parts to cubic ones in less than two minutes.

The 2-jaw module can handle turning applications up to 1,500 rpm. Due to its compact profile, it is well-suited as an alternative to large and heavy centric vises. The 2-jaw and 3-jaw module both use the Hainbuch collet chuck as their base. Changeover is possible without removing the collet chuck and realignment due to the Centrex quick-change interface.

According to the company, Hainbuch’s modular system enables a wide variety of workholding configurations to accommodate round, prismatic, small or larger components. The various workholding adapters can be installed in two minutes or less. Round workpieces are clamped from the outside with clamping heads (collets) within the collet chuck. Larger diameter workpieces, beyond the capacity of the collet chuck, can be clamped with the 3-jaw module.

RELATED CONTENT

-

4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

-

Selecting the Right Milling Tool for Any Machining Task

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.