MCC Lathes Improve Productivity, Operating Convenience

Appears in Print as: 'Lathes Improve Productivity, Operating Convenience'

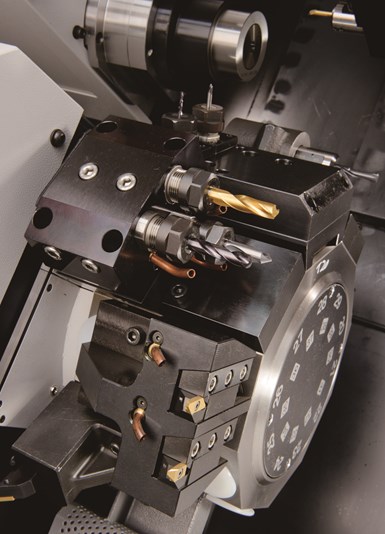

MCC’s M532 VIII and L12X have added capabilities to improve productivity.

Edited by Angela Osborne

Marubeni Citizen-Cincom’s (MCC) Citizen’s M532 VIII and the L12X are Swiss-style lathes with added functionalities for operating convenience and improved productivity, according to the company. The M532 VIII is a Citizen Cincom M series turret-style Swiss turning center with a 32 mm capacity machine that has the capability to increase to 38 mm. Its standard 12 cutting axes includes a B axis for angular drilling and contour milling, while the 10-station turret with half index capability provides 20 positions. The Cincom L212X features the all-axis simultaneous Cincom system M70 Control (Mitsubishi Meldas 70LPC-VU), as well as a 15,000-rpm main spindle. The machine has a Y2 axis on the back spindle which expands the range of usable tools. The maximum spindle speed has been increased to 12,000 rpm to shorten acceleration/deceleration times. The company says that both machines employ a user-friendly editing function which utilizes multiline, multi-axes programming along with superimposed and synchronized control to simplify setup.

RELATED CONTENT

-

Swiss-Type Machines: More Than Just a Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.

-

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.