A View Of Westec 2008

A View Of Westec 2008

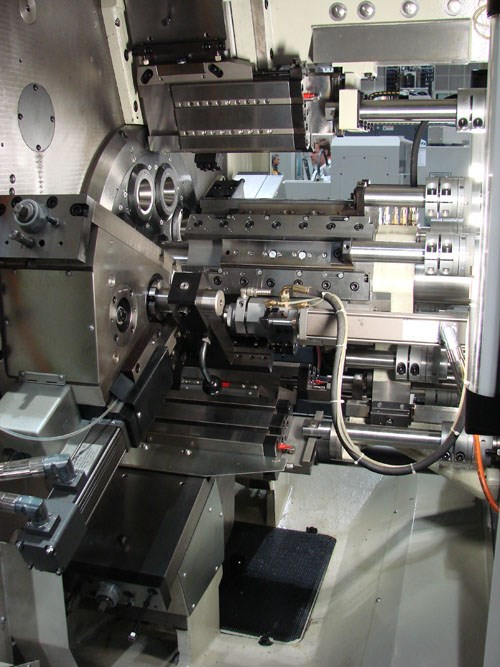

Mori Seiki had a number of machines to show. The NZ series of multi-axis machines features up to three turrets with Y-axis capability. Here's the NZ2000.

Haas’ prominent booth displayed a number of machines, including those from the SL series. The SL-30, with a max turning capacity of 17" x 34" and a 10" chuck, has a bar capacity of up to 3.0".

The Lico LNT 36, from Lipoco, has an 8-position tool turret with an indexing time of 0.15 to 1.2 seconds. To optimize cycle times, 3 to 5 tools can work simultaneously.

.jpg;width=860)

The CTX 310 Eco universal turning lathe from DMG features driven tools in all stations and a Y axis for eccentric boring and milling applications. It also includes a programmable tailstock and digital servo drives.

Star had on display its new Ecas-20T 12-axis Swiss machine. The independent three-turret design allows three tools to be used at any time, working simultaneously in the cut.

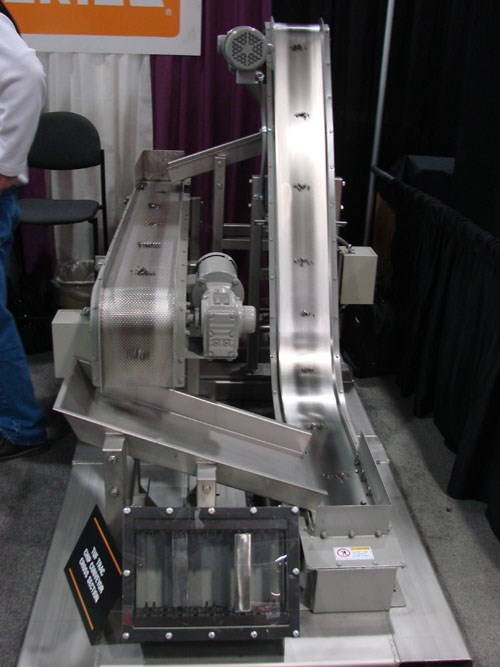

Tuf-Trac magnetic chip and parts conveyors use magnets that move inside an air-tight, submersible housing to attract ferrous chips, turns, small parts and stampings and convey them for discharge. At the show, the conveyor was displayed in operation, carrying chips up a 75-degree incline. A cross section of the belt system was also shown (bottom of photo).

Along with a number of other machines carried under its umbrella, Gosiger Import was showing the Euroturn 8/32 8-spindle automatic lathe with 3-axis backworking capability. It features eight independent longitudinal slides, eight cross slides and four compound slides for single-point turning.

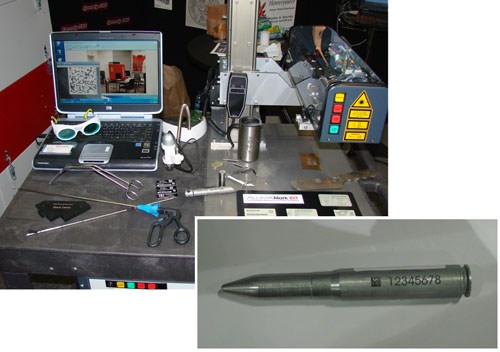

This typical shop workstation was set up in the Trotec booth to show an assortment of applications for the company’s laser marking and cutting products. Examples of the work included marking of carbide cutting tools, screw heads for medical applications and unique identifier (UID) marking for government and military applications (see inset).

Besides the cool deck of playing cards that Hardinge Workholding was giving away in its booth, products such as collets and collet blocks, guide bushings and bar loader collets were bringing attendees in.

MTA International had its new Tracer hydrodynamic Swiss magazine bar feeder up and running in the Star booth. External LED lights run the length of the bar, displaying operational status and remaining bar length.

The Micro line of CNC Swiss-types from Tornos provides a fast, flexible and affordable option for shops that are looking to replace their manual automatics.

The Mytrunnion-1 5-axis machining center, from Kitamura, features a trunnion design for table rigidity and machining accuracy. Positioning Accuracy is +/-0.00004” full stroke and repeatability is +/-0.00002”.

Siemens controls could be found in various booths around the show floor, including DMG, Lipoco and Star. The Sinumerik 802D solution line is an operator panel-based control system that combines the numerical control (NC), the programmable logic controller (PLC) and the human machine interface (HMI) in a single unit. It has capability for five-axis machining (two of which may be spindles).

The special effects artistic crew from FXperts Inc. displayed its 18-foot tall Bumblebee Transformer, which was designed with the assistance of Surfcam Velocity software from Surfware.

The Cincom A20 sliding headstock CNC automatic lathe was a popular machine in the Marubeni booth. This machine is designed to allow a cost-effective entry into Swiss machining while still bringing a solid allotment of features and performance.

Rego-Fix displayed its line of Swiss-type tooling and cylindrical toolholders. These ER collet holders provide for a range of applications in Swiss-type automatics as well as serving as extensions in milling, drilling or reaming applications.

The XP12S entry-level Swiss machine from Hanwha Machinery is designed for high-precision, yet simple Swiss turning. It features a maximum rpm of 12,000 and capacity for 6 OD tools, 3 front tools and 3 cross tools.