Editorial, News, and Products

Precision Machining Technology Review November 2023

Production Machining’s November 2023 technology showcase includes some of the latest technology from Horn USA Inc., Mazak North America, Kyocera SGS Precision Tools Inc., Big Daishowa Inc., Sandvik Coromant and Hamar Laser Instruments Inc.

Horn Tool Configurator Shortens Lead Times

The HTC system enables quotations to be generated within one working day, with technical drawings available the next working day.

Seeing Multitasking, Automation and Digitalization at Index’s 2023 Open House

A mini trade show of sorts, the event held earlier this year in Germany offered an opportunity to see the machine tool builder’s equipment in action as well as take tours of its various manufacturing plants.

‘Twas the Season for Equipment Manufacturer Open Houses

I’ve recently traveled to Germany three times to attend four separate manufacturer open houses. Here’s a taste of what I’ve seen.

E-Mobility — Opportunity, Not Existential Crisis

“We firmly believe that e-mobility presents a significant opportunity for innovation and growth.” — Markus Horn

Adjustable Damped Boring Bar Enables Vibration-Free Grooving Process

The boring bar can be precisely set according to the vibration occurring in each application.

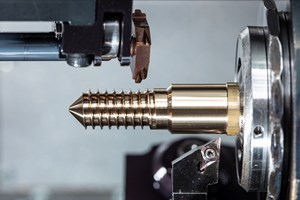

Horn Supermini HP Performs Multiple Functions as One Tool

PMTS 2023: The cutting concept enables higher infeed rates compared to standard small bore tooling.

Horn Mourns Loss of Corporate Leader Lothar Horn

Lothar Horn served as managing director of Paul Horn GmbH in Tübingen, Germany, since 1995.

4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

Manufacturing in the US Economy — and Our Place in It

Manufacturing is essential to our economy and Precision Machining is just as essential to manufacturing.

Horn Carbide Grades for High-Feed Milling

IMTS 2022: The SC6A and IG6B grades complement the tool system for high-feed milling and enable customers to choose the grades best adapted to their machining applications.

Horn Supermini Set Offers Greater Holding Force

The Supermini toolholder system offers clamping carried out via a clamping wedge on the face.

Horn 304 Milling System for Small Threads

The company says the vibration-dampening carbide shanks with integral through-coolant ports make the system versatile and easy to use.

Horn USA Tool Coatings Designed for Faster Removal Rates, Extended Service Life

Horn’s IG6 and SG3 coatings for cartridge tooling systems are said to deliver outstanding performance with difficult-to-machine materials.

Happy Workers are Good Workers

According to an extensive study in 2019 by the Oxford University’s Saïd Business School, a conclusive link between happiness and productivity was found — happy workers are 13% more productive.

Horn’s New FB Geometry Standardizes Special Cutting for Finishing Grooves

Company says new cutting geometry makes high surface quality possible without any problems in the finishing process, even when the conditions are unstable.

PMTS 2021 Product Preview: Cutting Tools and Toolholders

Production Machining highlights some of the upcoming cutting tool and toolholder products to be unveiled at PMTS 2021.

Horn’s DDHM CVD Diamond-Tipped Tool System Enables Machining on Milling, Turning Centers

The diamond tools enable shorter throughput times, high surface quality, lower overall costs, greater flexibility within the production process and longer tool life.

Horn EH Geometry for Grooving System Enables Parting Off at High Feed Rates

The stable cutting edge of the EH geometry ensures reliable chip evacuation and control.

Precision Machining Technology Review: Cutting Tool Technology

Production Machining showcases some of the latest cutting tool technology from Horn, Heimatec, Big Kaiser, Tungaloy and Inovatools.

Horn Supermini Clamping System Increases Repeatability

Clamping method enables cutting inserts to be held in place with more force, which, in turn, makes the entire system more rigid and results in higher repeatability.

Ventilator Crisis — Clippard Delivers for Ford

Clippard Instrument Laboratory Inc. in Cincinnati, Ohio, harnessed their talent, experience, capabilities and PMPA network to deliver 50,000 sets of ventilator parts to Ford Motor Company.

Horn Supermini HP Eliminates Need for Multiple Tools

Supermini HP is a multifunctional tool for drilling, turning, boring and facing.

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

Emerging Leader Lindsey Bender Offers Customer Service Excellence

Lindsey’s communication skills and talent shine through via her daily work at Horn USA.

4 Questions for Customer Delight

Operational excellence, product leadership, customer intimacy—one of these rules them all. Miles Free visited PMPA member, Horn, at its headquarters in Germany and returned home with four questions that can be used to determine customer delight.

Horn USA Commits to Thinking Globally, Acting Locally

By moving manufacturing operations closer to the people who use the product, Horn has proven its commitment to the simple philosophy of “think globally, act locally.”

Horn Swiss-Lathes Includes Stable Quick-Change System

PMTS 2019: Horn is focused on equipping Swiss-type lathes with a precise, repeatable and stable quick-change system.

2019 German Precision Tool Industry Outlook is Positive Amid Uncertainty

Despite geopolitical economic uncertainty, the German VDMA Precision Tools Association is projecting growth in precision tool consumption.

Giving New Methods of Thread Cutting a Whirl

Two new forms of thread whirling promise to make the thread cutting process more efficient.

Growing for 20 Years, and It Shows

The previous 50 × 50-foot booth that Horn USA occupied since 2008 is now 50 × 100 feet at this year’s IMTS.

Emerging Leader Janie Hughes Works to Bridge the Industry’s Generational Gap

Meet Janie Hughes, quality specialist at Horn USA. She has been nominated and chosen as one of Production Machining’s 2018 Emerging Leaders—a young professional making strides as a leader in the industry.

Challenging Factors in Turning Tightly Toleranced Parts

This shop produces 100 housing covers made of high-tensile aluminum every year, and has reinvented and improved its machining processes in order to face the challenge of thin walls.

Production Machining 2018 Emerging Leaders

Young professionals are a vital asset to the precision machined parts industry, and it is important to acknowledge those who are making strides toward shaping the industry’s future. Production Machining is recognizing our industry’s young talent who were nominated by their peers through our new Emerging Leaders program.

Turning Thin-Walled Aerospace Parts

To produce extremely small, complex, tightly toleranced, thin-walled precision components made of difficult-to-machine materials, such as high-tensile aluminum housing covers, Herrmann CNC-Drehtechnik is reinventing and improving its machining processes.

Two New Twists on Thread Whirling

Thread whirling as a metalworking process dates to the 1940s. Recently, developments in production speeds, based on this increasingly popular process, are impacting thread manufacturers.

Paul Horn Facility Showcases its Expertise

Paul Horn GmbH’s facility in Tübingen, Germany, is impressive not only because of its cleanliness, but the size of the campus and the company’s fast growth from year to year.

Training Through German Eyes: Not What You Expect

HORN pays strict attention to assure the people that the company understands the importance of, and are capable of, working with others. Its focus is on using the strengths of each person for the benefit of the whole.

Technology or People?

In your shop, do your people operate your machines? What impressed me the most was the implicit, built-in assumptions at HORN that it was the people leading the machine tools, rather than the machine tools leading the people.

Paul Horn Keeps Moving Forward

Since I visited Horn in Germany two years ago, it has doubled its production floor with an investment of 70 million Euros.

PMPA Chapter Meeting Covers Threading

The PMPA Indiana/Southern Ohio Chapter meeting on November 15 covered “All Things Threading,” with presentations from Horn USA and LMT Tools (Fette), and included live threading demonstrations on the Technical Equipment's showroom floor.

Take This Tool for a Spin

Turbo whirling is a newly developed process from Horn USA that optimizes machining during thread whirling, boosting both productivity and cost-effectiveness.

A Grand Event in Grand Rapids

The 2016 PMPA National Technical Conference provided three days of powerful sessions to hundreds of attendees eager to support their industry and improve their own business acumen.

Cutting into the Workforce Shortage

On Manufacturing Day, which was October 2 this year, students from Williamson County, Tennessee, toured multiple manufacturing facilities, one being Horn USA, to obtain a firsthand look at local career opportunities.

The Transition to No-Lead Brass

Adjustments to feeds and speeds, coolant, tooling and scrap management all play a significant role in allowing a productive switch to unleaded brass.

6 Lessons I Learned about our Machining Business

Last month, I was privileged to attend Horn Technology Days. Here are the lessons I learned.

Training Your Apprentices: A Project to Prove their 'Mettle'

At the recent Horn Technology Days, I spent some time hanging out with the apprentices.

The Real Truth About the Skilled Workforce Issue

"The workforce and finding skilled people are our shop's biggest problems." I hear this line from almost every shop I visit.

Learning by Seeing

German cutting tool maker Horn hosted the fifth edition of its biennial Technology Days event.

Finding the Right Insert Eliminates Need for Second Machining Center

Read about this shop that could have added a second machine and fixtures to perform an additional process, but instead, decided to work with the Mori Seiki NH 4000 horizontal machining center that it already had in-house. The company elected to use two 90-degree milling heads to machine the flats that are made of 4140 steel.

Groove Milling Cuts Down Cycle Time for Inconel Part

When a shop tries to outsource a part, but no vendors want to take on the job, it’s time for that shop to figure out how to machine the job on its own.

When to Consider Customized Cutting Tools

What is the real cost of choosing standard or customized tooling if time is money and efficiency translates into profits? It’s a question many shops face regularly.

Making Cutting Tools in New Ways

Horn began operations in 1969 with a focus on grooving tools. Today, it is represented in more than 70 countries and has expanded its tooling business to threading, interpolated milling, axial grooving, drilling, reaming and broaching.

Coming Attractions

I recently returned from a trip to tooling manufacturer PH Horn.

Medical Shop Increases Tool Life with Hex Broaching

A manufacturer of spinal implants and surgical instruments achieves immediate results in a switch from rotary broaching to hex broaching.

Broaching on CNC Machines

This summary of a technical presentation from the Technology Days event at Paul Horn GmbH in Tübingen, Germany, discusses process analysis for broaching on CNC machines.

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

Technical Member Profile: Horn USA Inc.

Horn USA Inc. is the United States representative of Hartmetall-Werkzeugfabrik Paul Horn GmbH, which was founded in Germany in 1969.

Strategy Change Leads to Performance Boost

The application of a Horn Type 636 slot milling cutter has set new standards of accuracy, tool life, process reliability and costs for milling recesses on planetary gears at Sitec Aerospace in Bad Tölz, Bavaria, Germany.

Creating the Indexable Insert

In the shop, we are often told how to use a cutting tool, but not necessary the mechanics behind the tool itself or how the tool is manufactured. A few articles Production Machining has published in the past discuss this topic.

Manufacturing In The USA

Horn USA believes in being involved in the manufacturing community. Membership in the PMPA as a technical member and in the ISMA has afforded us the opportunity to learn about the difficulties others in the manufacturing community have faced during the economic slowdown and what is being done about it.

The Art And Science Of Precision Cutting Tools

Machine tools become faster and more stable while cutting tools get tougher, longer lasting and geometrically more complex. I visited a premier German cutting tool manufacturer to look at the state of the art of making carbide cutting tools that complement today’s machine tool technology.

Broaching On A Lathe

Producing a keyway, spline or similar longitudinal feature on a turned part usually necessitates an additional, time-consuming, secondary operation on a broaching or slotting machine. That means moving the part to and from a secondary operation, an extra setup, additional labor and hourly machine costs and all of the other headaches that go with secondary operations.