Editorial, News, and Products

DMG MORI’s Flexible Matris Light Cobot for Quick Deployment

This space-saving, flexible automation solution is intended for efficient variable-mix and variable-volume production, and is compatible with a wide range of turning centers and machining centers.

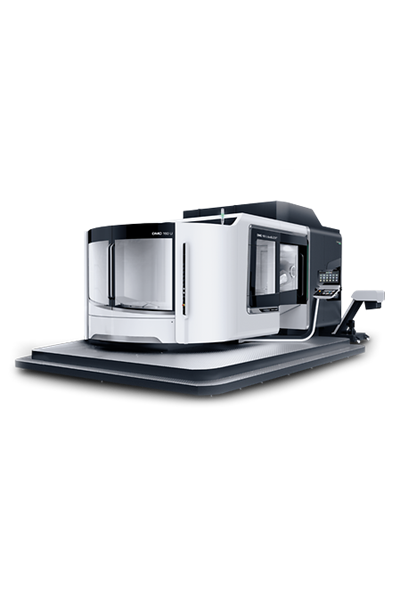

DMG MORI’s NTX 500 Compact Turn-Mill for Complete Machining

Compact turn-mill is designed to be a versatile manufacturing solution for machining increasingly complex workpieces.

Growth Comes When Machining Challenges Are Met

Manufacturers such as SDP/SI that embrace machining challenges ultimately find ways to become more efficient and profitable operations.

Five-Axis Fixturing Fun

This shop creates intricate fixtures — some of which it has given interesting names — for very complex jobs and high-volume work on five-axis machining equipment.

Production Machining’s May 2022 News Highlights

Some of the cutting industry’s latest news includes research and development for new digitization solutions/processes, comprehensive applications support with specialized production technologies, e-commerce, advanced analytics and more.

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

Shop Optimizes its Swiss-Turning Flexibility

Paramount Machine uses various Swiss-type lathes, some with a B axis, to produce parts more effectively than it did on conventional chucker lathes. Today, nearly every job under 1.5 inches in diameter runs across those machines even if the batch size is a mere 5 pieces.

DMG MORI Holds Digital Open House Feb. 2-4

Event includes live presentations, expert talks in six languages and a digital showroom with over 25 exhibits.

DMG MORI Partners with IN4.OS, Pickens CTC

DMG MORI's machines can now be found in the IPSUM Technologies Smart Factory of the Future, as well as the Pickens County Career and Technology Center.

Tooling System Reduces Setup Time So Shop Stays Competitive

Turret adapted clamping units and quick-change tooling systems have helped a company use its new turning centers more effectively, so it can win new business in a competitive environment.

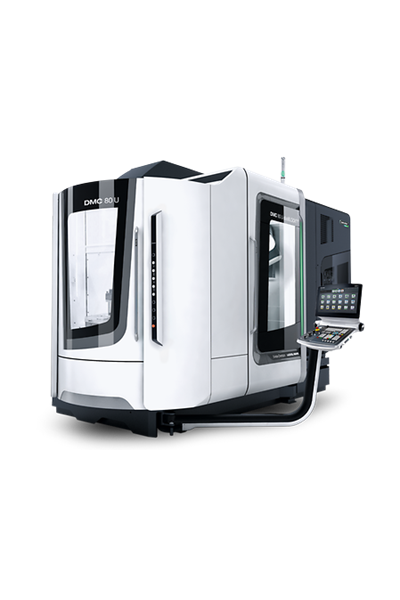

Chicago Innovation Days Emphasize Advanced Technology

DMG MORI Chicago Innovation Days highlighted integrated digitization, automation solutions and additive manufacturing while introducing two machines to the U.S. market.

Transformation of Powertrains is a Chance for Growth

We recently talked with Dr. Masahiko Mori, president of DMG MORI Co. Ltd., about what a shift towards alternative drives and changing requirements on combustion engines means for the machine tool builder’s future.

An Unconventional Approach to Multi-Spindle Production

This shop went with its gut, pushing back on the suppliers who said, "You're making a mistake." It's creative use of multi-spindle technology for small lot sizes is no mistake.

Learn How to Increase Productivity at IMTS

Exhibitors at the IMTS 2018 Metal Cutting Pavilion will feature smart machining technology including connectivity, automation, process integration and updated controls that can increase productivity.

Challenging Factors in Turning Tightly Toleranced Parts

This shop produces 100 housing covers made of high-tensile aluminum every year, and has reinvented and improved its machining processes in order to face the challenge of thin walls.

A Lesson about Automation

The advantages of automation on the shop floor can run deep, but many shops struggle with determining the best starting point.

Turning Thin-Walled Aerospace Parts

To produce extremely small, complex, tightly toleranced, thin-walled precision components made of difficult-to-machine materials, such as high-tensile aluminum housing covers, Herrmann CNC-Drehtechnik is reinventing and improving its machining processes.

DMG MORI USA Appoints James V. Nudo as President

DMG MORI USA has appointed James V. Nudo, who has been with the company for over 14 years, as the president of the organization as of December 7, 2017.

CVG-6 Vertical Cylindrical Grinder Has Pallet Changer

Taiyo Koki Grinding Machine Co.’s CVG-6 vertical universal cylindrical grinding machine with pallet changer is able to grind OD, ID and faces all in one part chucking.

DMG MORI Hosts Cincinnati Grand Opening

DMG MORI’s Cincinnati grand opening was held at the company’s 14,500-square-foot Cincinnati Technology Center on August 15-17 and features a showroom for test cuts and demos by 18 individuals, including nine in service, three in applications, and six in sales.

Sandvik Coromant Becomes DMG MORI Premium Partner

The relationship will combine the two companies' expertise in projects including R&D, engineering, open house events, trade show appearances and technical seminars.

DMG MORI's Direct Sales and Service Initiative Update

DMG MORI now has direct sales and service in all regions of the U.S. with the exception of four. Each of the technology centers have regional directors and area sales managers.

A Grand Event in Grand Rapids

The 2016 PMPA National Technical Conference provided three days of powerful sessions to hundreds of attendees eager to support their industry and improve their own business acumen.

Changes for DMG MORI in the USA

A new sales and service model will connect DMG MORI USA employees directly to customers in order to more efficiently speed up critical processes, such as managing service support and sharing new product improvements for U.S. customers.

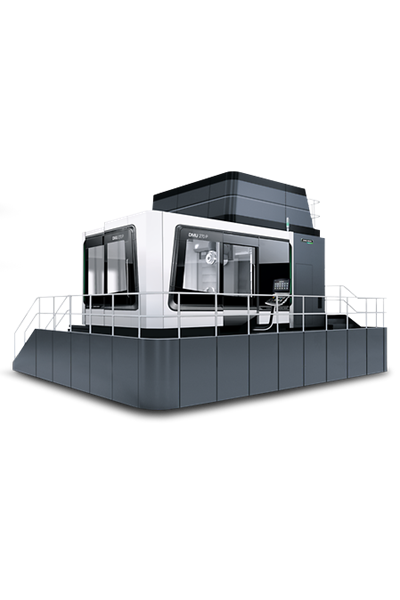

Seven World Premiers Highlighted at Innovation Days Event in Japan

During DMG MORI's “Innovation Days” event July 22-25 in Japan, the company showcased 58 machine tools in its newly renovated Iga Global Solution Center, which boasts 3,500 m2 (37,674 ft.2) of floor space.

Chicago Innovation Days 2015

DMG MORI held its Chicago Innovation Days 2015 event in May, with more than 30 high-tech exhibits, including two U.S. premieres.

Adding Swiss to the Machining Mix

Augmenting this Ohio shop’s machining center based-business with Swiss-type machining capability speaks to trends within the metalworking industry. And it’s working well.

CAM Software Enables Machining Complex Parts Faster, in More Ways

When Advance Manufacturing Technology (Salt Lake City, Utah) acquired a multitasking machine in 2012, it licensed GibbsCAM MTM (multitask machining) software from Gibbs and Associates Inc. to enable programming the new machine.

High Productivity Through Remote Machine Monitoring

As of June 1, all new DMG/Mori Seiki machines equipped with MAPPS control come installed with an MTConnect Standard V1.1 compliant MTConnect adapter.

Making Cutting Tools in New Ways

Horn began operations in 1969 with a focus on grooving tools. Today, it is represented in more than 70 countries and has expanded its tooling business to threading, interpolated milling, axial grooving, drilling, reaming and broaching.

Seco Inks Sponsorship Deal with Andretti Autosport

Metalcutting solutions provider Seco Tools recently signed on as a technical and supplier sponsor of the Izod IndyCar Series championship racing team Andretti Autosport.

Consolidating CAM Software Cuts Programming Time

At Trillium Machine Inc., there’s no room for thinking within the comfy confines of “the box,” working in the “comfort zone,” or refusing to try the untried.

A First for DMG/Mori Seiki USA

DMG/Mori Seiki USA President, Mark Mohr, and Chief Learning Officer, Rod Jones, accept the NIMS accreditation certificate at the company’s Innovation Days. At its recent Innovation Days in Chicago, DMG/Mori Seiki USA announced that its training center, DMG/Mori Seiki University (DMSU) is the latest addition to the network of National Institute for Metalworking Skills (NIMS)-accredited training programs.

Shop Grows its Multitasking Operations

Here's a look at what this shop's expanded multitasking capabilities have meant to its success and how it plans to continue building momentum.

DMG/Mori Seiki USA Plans Innovation Days Event

DMG/Mori Seiki USA will host Innovation Days 2013 at its U.S. headquarters near Chicago, Ill., May 7-10.

Process Integration Boosts American Manufacturing

After the traditional summer slowdown in machine tool orders, it was encouraging to see the activity in September.

New Machine for Production Turning

In February, PM was invited to a DMG/Mori Seiki press conference at the company’s facility in Pfronten, Germany.

Made in the USA

Mark Mohr, the recently appointed president of DMG/Mori Seiki USA, provided Production Machining with some thoughtful answers to questions about his role with the company and the new North American manufacturing plant scheduled to open in the fall of 2012.Production Machining: What is your background that led to your position as president of DMG/Mori Seiki USA?Mark Mohr: After 15 years of prior experience in the machine tool business, I joined Mori Seiki in 2002 as sales manager in the Chicago Technical Center.

Turn-Mill Classics

Here are trailers for some of the classic articles on turn-mill multitasking. This is a broad showing of turn-mill technology in the form of machines, processes, programming and applications.

PM News: March 2011

Cleaning Technologies Group Names New PresidentTim Piazza was named president of Blackstone-NEY Ultrasonics.

PM News: February 2011

New Engineering Manager Hanwha Machinery America has appointed David Folz as engineering manager at its Franklin, Wisconsin, headquarters.

PM News: October 2010

Live Tooling Manufacturer Opens U.S.

CNC Lathes, Machining Centers and More

The company’s Mori Seiki NT1000SZM, as well as the DMG CTX gamma 2000 TC are available.

Making Hire to Retire Work

This Canadian shop builds its succes around advanced machine tool tecnology, such as turn-mill, and an enlightened approach to employee relations.

May 2010 News

New Sales ManagerRandy Flores has been selected to lead Hurco Companies Inc.’s direct sales initiative in Southern California.

April 2010 PM News

Manager of Strategic ProgramsSeco Tools Inc. has appointed Tracie Clarke as its manager of strategic programs.

Turning/Milling Machine with 2 Toolholders

DMG has added a machine to its series of turning/milling centers: the CTX gamma 2000 TC with a B axis and high speed 12-station turret, two-channel control and the multi-channel programming system, ShopTurn 3G. The design permits four-axis machining on one spindle or parallel machining on the main and counter-spindle, plus a range of additional manufacturing options.

Gaining Better Sight for Productivity

American Optisurgical Inc. (AOI) products help people have a clearer view of life and their surroundings.

November 2009 News

Software Certified by Autodesk InventorGibbs and Associates’ GibbsCAM 2009 has been certified for Autodesk Inventor 2010 software under the Autodesk Inventor Certified Applications Program. Certification is granted only after a product has been thoroughly tested by internal staff at Autodesk.

Laser Highlights

The number of different laser applications is surprising, yet it continues to grow. Here's a look at a few.

CAM For Multitasking Operations

While still running a few different CAM systems in the shop, this manufacturer of aerospace and oil and gas industry components has implemented what it sees as the ideal package for programming its multitasking work.

Universal Lathe Improves Turning Capability

Peter Brotherhood (Peterborough, United Kingdom), a steam turbine manufacturer, recently discovered a bottleneck when turning a range of power-generation components. When the company implemented a Gildemeister CTX 620 V4 linear universal turn-mill center by DMG, however, the problem fixed itself.

When To Combine Milling And Turning

Turn/Mill technology enables users to complete a workpiece in a single handling. This article looks at some of the criteria that make application of this multi-tasking productive.

Revisiting An Intriguing CNC Multi-Spindle Experiment

Otto Engineering is a manufacturer of mechanical switches and related products. The vertically-integrated company has its own machine shop, which produces many of the switch components that supply the company’s assembly lines. Like most other manufacturing firms, Otto was looking for ways to cut costs and improve the efficiency of its manufacturing operations.

Laser Simplifies Form Tool Chip Control

The creation of a 'bird nest' is a problem for any turning operation. These uncontrolled wads of chips tend to wreck havoc on tooling, equipment and continuous operations.

Seeing A Multi Through Different Eyes

Sometimes if you don’t 'know' any better, applying technology in new ways simply makes sense. That’s partly what helped drive this family-owned OEM to acquire its first, and so far only, multi-spindle to help it get a better handle on production and inventory control.

CNC Multi-Spindle Offers New Feature Combos For Lower Cost Per Part

Not too long ago, if cycle time was the primary consideration when buying a new multi- spindle machine, the choice was automatic—cam automatic, that is. Today, CNC multi-spindle machines offer cycle times comparable to those for cam automatics and a great deal more. Builders of CNC multi-spindles have discovered more ways to computerize their machines, providing packages of features that raise their productivity to a new level.

Fighting Pressure With Pressure

High-pressure coolant systems are providing improved part quality, increased tool life and other benefits for this precision turning shop.

Linear Motors On Multis

A primary objective for multi-spindle screw machines, or any metalcutting machine tool, is to accurately and rapidly deliver a cutting tool to a workpiece while precisely controlling its cutting action.

Boosting Multi-Spindle Productivity

Here's a look at some of the ways Delta Faucet is taking advantage of off-the-shelf technology to improve multi-spindle screw machining productivity.