Editorial, News, and Products

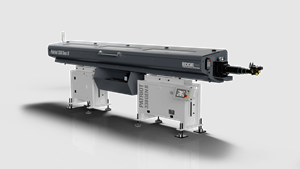

Bar Feeder Designed with Swiss-Types in Mind

New technology enables this bar feeder to fully support the bar pusher and stock from inside the unit all the way to the spindle of a sliding headstock lathe.

Edge Technologies Appoints New Sales Managers

Dan Borders has been promoted to national sales manager. The company has also hired Greg Haering as regional sales manager for the mid-Atlantic territory.

Video Tech Brief: Bar Feeder Technology Optimized for Swiss-Types

This bar feeder design is said to offer high guidance quality with minimum vibration and noise development for sliding-headstock machines.

Shop Shares Lights-Out Lessons Learned

Automated machining and data collection have helped Custom Tool to not only grow its business through more overnight production but also to establish a continuous improvement mindset that has enabled it to become more efficient in numerous areas.

Magazine Bar Feeder Enables Unattended Operation

IMTS 2022: Edge Technologies’ Commander 8-80 magazine bar feeder enables unattended operation with its large magazine capacity.

RW Screw: Where Automating Processes is a Common Thread

This Northern Ohio contract machine shop increasingly integrates automation, in all its forms, as it adapts to the reality of a continually diminishing talent pool.

Carving Out a Niche in CNC Plastics Machining

This Vermont shop focuses solely on machining plastics — some filled with abrasive glass — for a range of industries. That makes it stand apart from others, but means it also faces challenges that metal machining shops often don’t encounter.

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

Edge Technologies' FMB Turbo 3-38 Feeds Round, Square and Hexagonal Bar

Quick-change polyurethane guide channels allow for quiet operation at high RPM cutting.

VIDEOS: PMTS 2019 In-Booth Demos, in Case You Missed Them

Find videos from in-booth demonstrations from Absolute Machine Tools, Edge Technologies, Gosiger, Hardinge, Index Corp., Marubeni Citizen, Tsugami, and ZPS.

Coolant Mist Collector Combines Centrifugal Separation with HEPA Filtration

Eastec 2019: Edge Technologies will exhibit the Vortex AF water-solubale coolant mist collection system designed for machine tools performing wet machining operations.

Edge Technologies Vortex System Designed for Wet Operations

PMTS 2019: Edge Technologies’ Vortex AF series is a soluble coolant mist collection system designed for machine tools performing wet machining operations.

Tsugami/Rem Sales Event to Feature Partner Presentations

Tsugami/Rem Sales will host the second annual Technology Center Open House, a two-day event that will consist of presentations by long-time industry partners, Esprit and Edge Technologies.

The Collet is the Answer

A small workholding change helped this shop deliver the required part finish by resolving vibration and runout issues.

Minimizing Personnel with Unattended Operations

Once a machine is cutting parts, the operator is free to perform other duties. It makes sense that the longer the machine can run unattended, the more of these other duties the operator would be able to perform.

Running Remotely

Everybody talks about unattended machining operations and many have implemented it in varying degrees. Since day one, this Dayton, Ohio shop has never operated any other way.

Barfeeding Small Diameters

This shop may be located off the beaten path but it’s certainly found a successful and profitable home by applying top of the line technology to its medical part production mix.

Connecting the Technologies

This Missouri shop uses new advances in machine to machine communications to achieve its goals of lights out manufacturing and quick changeover.

Bar Feed Considerations For High-Speed, Lights-Out Machining

There are design elements incorporated into today’s 12-foot, magazine-load bar feeders that make them more useful for high-speed and untended operation. This article looks at some aspects to consider before purchasing a 12-foot bar feeder.

Improved Parts Cleaning Technology Leads To Environmental Compliance

This company's aqueous parts washer's limitations and design were causing problems, which led the shop to purchase a parts cleaning technology that eliminated many of the parts cleaning processes it was doing at the time.