Editorial, News, and Products

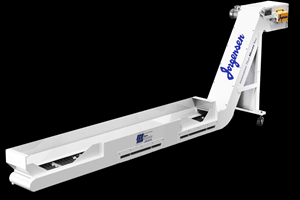

Jorgensen Auger Assist Reduces Frequent Hopper Unloads

The Auger Assist is said to reduce frequent hopper unload, enable machines to handle higher chip volumes and lessen the amount of labor needed for chip hopper management for increased productivity.

Modular Filtration Systems Offer Flexible Configurations

IMTS 2022: The Flex G Series of modular filtration systems are designed as cost-effective systems featuring pre-engineered modules that ensure fast, easy, flexible filtration configurations.

Jorgensen Chip Processing for Reducing Chip Volumes

The chip processing system is designed to easily and efficiently move chips from the manufacturing process to shredding, wringing and briquetting.

Munchman Conveyor Eliminates Production Line Downtime

Conveyor manages long, stringy and nested metal chips generated from high-speed turning and milling operations to eliminate expensive machine stoppage.

Jorgensen Conveyors Creates Partnership in Midwest

Jorgensen Conveyors Inc. has added The Whittemore Co. as its new manufacturers’ representative for nine mid-western states including Illinois, Iowa, Nebraska, Kansas, Missouri, Minnesota, South Dakota, North Dakota and Indiana.

Video: A Solution for Challenging Chip Removal

Depending on the material being machined, turning operations can produce tangles of chips that can clog single-belt conveyors. Read how one company found the solution with a double-belt design.

This Filtration System Takes The Cake

For chip removal and coolant filtration in many CNC machining operations, capital cost and proven efficiency still make disposable media designs the common choice. Permanent media chip removal and coolant filtration systems, however, have quickly become a viable option for helping to lower operating and maintenance costs in certain applications. In high-production operations, these systems can increase tooling life and coolant life and reduce nozzle clogging. The systems also are environmentally beneficial and provide cost savings related to media replacement and operator involvement.