Editorial, News, and Products

Okuma America Control Features Digital Twin Technology

The OSP-P500 control features dual-core processors that provide redundant operations, ensuring uninterrupted machining operations.

This Shop is Taking an Automated Aerospace Approach

A flexible manufacturing system helps an Indiana job shop run a mix of aerospace work for long stretches of time and function more like a contract shop.

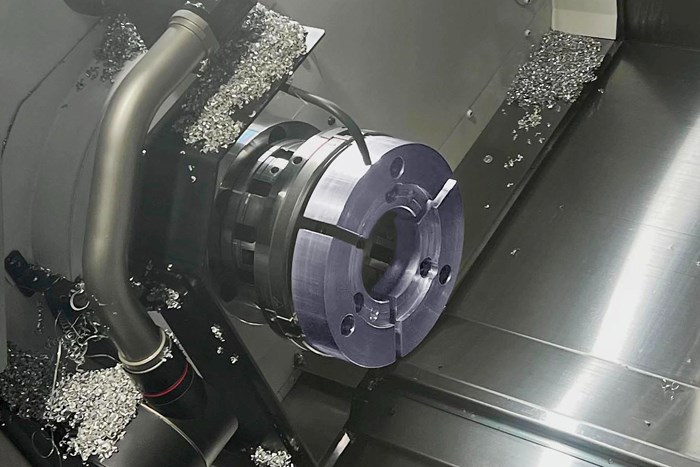

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Okuma America Receives Workplace Recognition Awards

The company has received two awards from Top Workplaces, an employer recognition organization.

Workholding Facilitates Fast Changeovers for Robotic Surface Finishing Systems Manufacturer

This manufacturer finds value in modular workholding technology to speed production of toolholders and other components used in its automated surface finishing systems.

Okuma Introduces New Okuma Factory Automation Division

Okuma America Corp. launches business segment focused on automation solutions for manufacturers

Reinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Okuma America Recognized as a Top Workplace in 2022

The Charlotte Observer granted a 2022 Top Workplace distinction to the company based on a survey that polled 24 different topics related to job satisfaction and company culture.

Shop Shares Lights-Out Lessons Learned

Automated machining and data collection have helped Custom Tool to not only grow its business through more overnight production but also to establish a continuous improvement mindset that has enabled it to become more efficient in numerous areas.

Adaptive Machining: The Last Puzzle Piece for Automated Production?

Automatically monitoring and adjusting cutting parameters inside a machine while checking for tool wear is just as important to establishing a reliable lights-out machining process as having a robot outside the machine.

3D Printing Creates a Window of Automation Opportunity

For this Omaha shop, periodic part inspection required an automated turning cell to pause production. Printing a plastic parts collection chute for delivery outside the cell solved this problem, and it turns out the shop has found 3D printing to be valuable in many other ways.

Morris Group, Okuma America Open Technical Center

Joint facility in Elgin, Illinois, will serve as a product showroom and technical center for machine tool users in the Midwest.

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop, PM’s sister brand, took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Horizontal Machining Center From Okuma Offers New Features

The machining center offers a larger work envelope, enhanced chip and coolant management functions and automation compatibility, among other features.

Some Assembly IS Required

This Colorado manufacturer added a separate facility dedicated to customer assembly work and inventory management to produce subassemblies and completed products primarily for medical customers.

A Shop Snapshot(s) in Time

Shamrock Precision has made significant strides to diversify its customer base and implement various process improvements, applying a crawl, walk, run approach to adding new technology such as ERP and automation.

Built-In Robot Optimizes Turning Processes

A robot integrated within CNC lathes enables part loading and unloading, chatter suppression and chip removal, ensuring that each machine is consistently operating at its highest efficiency.

Big Kaiser Presetter Option Speeds Data Transfer to Machining Centers

The system can also be configured to send measurements directly into the numerical control tool’s offset table.

Okuma Robotic Roid Series Offers Options for Machine Tending

Roid series provides simple, reliable robotics for automating machining tasks.

Turn-Mills: Being About the B-Axis

With the addition of powerful B-axis milling spindles and automatic toolchangers, turn-mills combine the best of milling and turning worlds.

CNC Apps You Possibly Didn’t Know You Could Benefit From

Some software capabilities go underutilized. One machine tool builder’s CNC software includes lesser-known apps that shops can leverage to their advantage.

Automatically Optimize Your CNC Machining Feed Rates

New feed-rate-optimization technology can enable CAM programmers to reduce cycle times and increase tool life for milling and turning operations.

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

An App to Simplify Setups

This shop, specializing in high precision parts for the semiconductor industry, worked closely with its machine tool supplier to develop an app that drastically reduces setup times.

Okuma Welcomes Open Mind Technologies to Partners in THINC

Software developer offers five-axis and multifunction CAD/CAM solutions for CNC machine tools.

Okuma Names Vice President of Finance

Summer Cline brings several years of finance experience to her new role.

Load & Go Robot Eases Automation for CNC Shops

This compact robotic loading platform makes automation affordable for CNC shops.

Multitasking CNC Lathe Machines Process-Intensive Parts

The Multus U3000 imultitasking two-saddle CNC lathe provides a platform for long-term rigidity and accuracy and can machine process-intensive parts, such as those in aerospace, automotive, oil/energy, medical and construction.

Multitasking CNC Combines Additive and Subtractive Machining

Okuma’s MU-8000V Laser EX multitasking CNC machine combines laser additive technology with subtractive machining capabilities, implementing laser metal deposition (LMD) technology with the ability to cut unique parts of many different sizes and shapes.

Genos M460V-5AX VMC Cuts a Variety of Materials

Okuma’s Genos M460V-5AX vertical machining center has a solid double-column structure, full five-axis simultaneous control and thermal stability performance that give it the ability to cut a variety of materials.

MA-12500HW HMC Cuts Exotic Materials

Okuma America Corp.’s MA-12500HW horizontal machining center is suited for large-part aerospace machining and has a W axis that allows for a longer tool stroke to machine complex, difficult-to-reach part features.

GA26W Grinder is Equipped with Intelligent Control

Okuma’s GA26W high-speed, compact grinder is now equipped with the intelligent OSP-P300G CNC control that integrates the machine, motors, drives and encoders, allowing for machine performance and customization to suit machining needs.

The Effects of Automation on Manufacturing

Companies that are not currently using automation in their manufacturing processes should be considering it.

Genos M560-V VMC Machines an Assortment of Parts

Okuma’s Genos M560-V vertical machining center combines a high column design and CAT 40 Big-Plus spindle to cut large, complex parts with a larger work envelope that minimizes restrictions on workpieces, tool lengths and the rotary table.

VIDEO: Highlights from Okuma’s Winter Showcase

More than 700 machine tool professionals visited Okuma’s 2018 Winter Showcase to see the company’s latest developments in additive and other manufacturing technologies. Check out video of the event.

2SP-150H Horizontal CNC Lathe is Compact and Flexible

Okuma’s 2SP-150H horizontal twin spindle lathe offers high metal removal rates in a small space and can be used for small part CNC machining, with front-facing spindles allowing access to the workpiece and tooling.

VIDEO: Okuma Summer Showcase Event Highlights

Here’s a video with highlights of Okuma America Corp.’s Summer Showcase event, which included educational presentations and cutting demos on more than 15 machine tools.

The Advantages of Hand Scraping

On my recent trip to Taiwan, almost every one of the machine tool builders we visited made a point to demonstrate to us that they still highly value the art of hand scraping. Learn more about the benefits this process brings.

Video: Watch Flat Turning for Machining Polygons

Machining flats in a single handling is shown on this video from Okuma. The workpiece and cutter are rotated synchronously with a defined rotation frequency ratio, depending on the number of lobes needed to be machined.

Robotic Cell Cuts Cycle Time, Improves Part Quality

Sew-Eurodrive Inc. worked with Okuma America’s authorized systems dealer to design an automated cell that includes an automatic magazine bar feeder that loads 6-ft. lengths of barstock into the machine. The shop also switched to an Okuma twin spindle, twin turret turning center so all of the machining operations are completed in one setup.

Learning to Optimize Shopfloor Production

Okuma America Corp.’s annual Technology Showcase, held this month in Charlotte, North Carolina, featured the theme “Get Connected. Put IIoT to Work for You.”

Okuma and Chip Ganassi Host High School Students

Okuma and Chip Ganassi Racing gave high school students a behind–the-scenes tour of the race facility while discussing CNC machining technologies and careers.

Reducing Production Times with Robotic Automation

A complete overhaul of its processes using lean principles helped this shop improve production by almost 90 percent.

Okuma Donates CNC Machines to College

Okuma America Corporation recently donated an MC-V4020 CNC vertical machining center and an ES-L8II CNC lathe to the engineering technology programs at Central Piedmont Community College.

Energy-Efficient Machine Tool Technologies for Any Size Shop

Recognizing that advanced machine tool technology can be used as a highly effective energy-saving tactic, Okuma offers ECO Suite to reduce power consumption.

Keeping Energy Costs Down

This white paper provides information on energy-efficient technologies.

Expanding for the Future

This 2-day event showcased the expansion of Marubeni's New Jersey facility that went from 26,000 square feet to more than 42,000 square feet.

Video Series Demonstrates Gun Part Manufacturing

Videos show various firearms cut with high-speed precision on Okuma machining centers and a horizontal lathe.

Taking a Big Step

This Indiana shop made a leap from manual machining and basic CNC technology to a sophisticated turning cell and has not looked back. It's been a customer driven transition.

Okuma Launches Industry Parts Viewer

The company's interactive Industry Parts Viewer provides users with a view of assemblies and parts from the automotive, aerospace, and oil and energy industries.

It's an App World, Even Ours

In all walks of life these days, apps are springing up to make life easier and more productive. Machining businesses increasingly are no exception.

Okuma and Chip Ganassi Racing Teams Expand Sponsorship

CNC machine tool manufacturer Okuma America Corp. and Chip Ganassi Racing Teams have expanded their partnership agreement to include the No. 1 Chevrolet SS, driven by Jamie McMurray in the NASCAR Sprint Cup Series.

Everybody Talks About the Skills Gap, But Some are Doing Something About It

One recent effort to help change the skills gap was hosted by Okuma America at the company’s headquarters in Charlotte, North Carolina.

'Make the Leap' at Okuma's Technology Showcase Event

A trip to Okuma headquarters in Charlotte, depending on where you live, might be a respite come December 9-10 when the company hosts its technology showcase.

White Paper Describes Preventing Chatter on CNC Lathes

Okuma's VSST and HSSC allow users to cut threads without chatter.

VIDEO: Okuma Hits the Refresh Button for its NASCAR

The new paint scheme car celebrates a longstanding, productive partnership between Okuma and RCR.

Okuma America’s 2013 Technology Showcase

Okuma America Corporation’s Technology Showcase event, held December 10-12, 2013 in Charlotte, N.C., was the company’s largest to date, both in attendance and the number of CNC machines shown.

Hard Turning’s Strong Finish

With the right methodology in place, this alternative to grinding can often save money while adequately meeting surface finish requirements.

Okuma’s OSP Control is 50 Years Old

In 1963, Okuma introduced its first CNC the OSP. OSP stands for Okuma sampling path, which emphasized the innovation of creating a digital representation of a machine tool’s cutting path.

Video: Company Evolves from a Manual Shop to a High Precision Success Story

Ian and Jack Wagter, owners of Lumar Machining & Manufacturing Ltd. of St. Thomas, Ontario, Canada, purchased the company with a customer base of two automotive plants. Today, Lumar Machining has a thriving business with plans to expand, adding even more machining technology.

Okuma Opens New High-Efficiency Factory

Okuma Corporation has held a formal dedication ceremony celebrating the opening of the first building of its new manufacturing facilities in Oguchi, Japan.

Shopfloor Data and the Future of Manufacturing

Redundancy is far too common in many areas of life. Standardized processes that streamline production might be the perfect solution.

Shop Grows its Multitasking Operations

Here's a look at what this shop's expanded multitasking capabilities have meant to its success and how it plans to continue building momentum.

Multitasking Capabilities Help Shop Stay Ahead of Orders

With the new Okuma CNC lathe multitasking production center, this company is increasing the size of its net, going after new markets, taking a hard look at aerospace engine coolers and a large array of medical applications.

Robots Drive High-Performance Manufacturing

As anticipated, IMTS brought a nice list of technological eye-openers.

Increasing Business with Hard Turning

By gaining experience in hard turning, a shop adds to its arsenal a cost-effective alternative to grinding, opening doors to new opportunities.

3D Monitoring and Part Verification

Using verification software provided by its machine tool supplier, this shop proves out parts well before any cutting takes place.

Advantages of Remote Troubleshooting

Read how remote diagnostics can allow a technician to troubleshoot a machine's issues or refine part programs from anywhere.

Connecting the Technologies

This Missouri shop uses new advances in machine to machine communications to achieve its goals of lights out manufacturing and quick changeover.

January 2010 News

600 Europe Appoints New Managing DirectorMike Berry has been appointed managing director of 600 Europe, responsible for managing and developing the Group’s newly centralized machine tool business in the U. K.

October 2009 News

October 2009 News

THINC Together

The belief that “two heads are better than one” has been taken to a new level. As the first facility of its kind, Partners in THINC is where a customer can come to see real parts being manufactured for real customers. In addition, this facility is where 26 of the industry’s leaders have committed products, engineers and time to reach out to the manufacturing industry to solve problems and create solutions as a team—a multi-discipline partnership.

Running A Good Race

For this Missouri job shop, it’s not about what you call the machine tool, it’s about how you use it. The shop considers multi-spindle turning as simply using more than one spindle in various configurations best suited to the production requirements of the application.

Turning On To Compact Bar Feeders

Compact bar feeders deliver the performance and capacity needed for this turning cell to run in a largely unattended mode.