Editorial, News, and Products

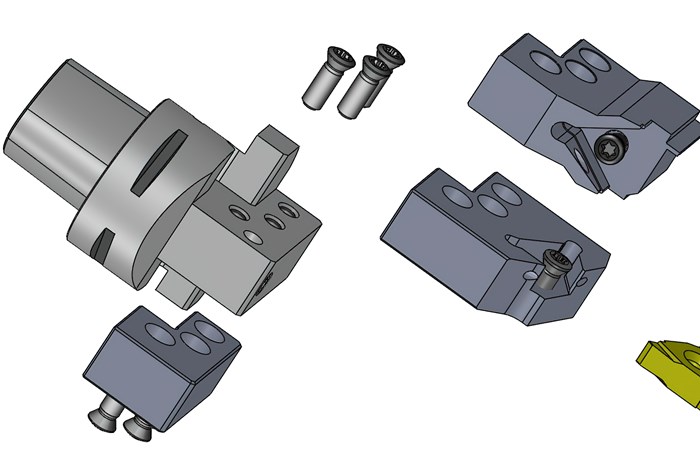

Goeltenbodt Pre-Settable, Quick-Changeable Tooling System for Swiss-Type Lathes

IMTS 2022: The company says the system can provide quick and easy tool changeovers and is pre-settable off the machine with repeatability of .0004″.

PMTS 2021 Product Preview: Cutting Tools and Toolholders

Production Machining highlights some of the upcoming cutting tool and toolholder products to be unveiled at PMTS 2021.

Modular Tooling System Features Coolant-Through Design

System enables faster tool changes as well as internal coolant delivery directly to the cutting edge.

Schwanog Expands its Tooling Line for Escomatic Machines

The cutting tool company now offers new toolholders for left- and right-handed applications on Escomatic machines.

Internal Grooves with 3-Sided Insertable Tool

The WEP insertable tooling system, which is individually ground based on part specifications, results in significant unit cost reductions because of substantial time savings during tool change-over as only the insert is indexed or exchanged and not the entire tool.

Insertable Form Tool Systems Save Money

PMTS 2019: The insertable tooling system from Schwanog LLC can be applied, but is not limited, to applications such as OD and ID grooving, form drilling, thread whirling, single-point threading, turning and milling, broaching of serrations, shaving and skiving, and polygon turning.

Schwanog's Insertable Tools Ground Individually

PMTS 2019: With its PWP and PWP-D insertable form drill system, Schwanog is said to address the problem of high setup times as the insert holder stays in the machine during insert changeover.

EDM and the Precision Parts Industry

Although EDM often is not at the forefront of concern for precision machined parts shops, it can play a big role in the production of tooling that these shops use.

Using Grinding Versus EDM to Finish Form Tools

Finishing carbide inserts using EDM or grinding.

Production Machining in Germany

This week I’m reporting from the Schwabian region of Germany, where metalworking has deep roots and good technology.

Save Time with Polygon Turning

Polygon turning provides the capability to manufacture both flat surfaces and radii.

Insertable Form Drill System Enables Company to Bore Large Diameters

Nass Magnet (Hanover, Germany) invested in a new machining center with a rotary transfer machine with eight stations for double-sided machining.

Insertable Form Drill System Provides Quality Surface Finish

To be able to manufacture the components of electro-pneumatic valves in production batches of millions, Nass Magnet (Hanover, Germany) invested in a new machining center with a rotary transfer machine with eight stations for double-sided machining, which came with drills from another supplier.

The Skiving Solution

Shaving operations are often the solution for a shop that needs to produce round diameters and other tough contours with tolerances within ± 0.0005 inch.

Insertable Form Drill System for Maximum Efficiency

In many applications, the switch from solid carbide drills to insertable form drills has shown to provide unit cost reductions of as much as 40 percent. As the demand for highly complex parts continues to rise, production improvements such as these become even more significant.

Creating the Indexable Insert

In the shop, we are often told how to use a cutting tool, but not necessary the mechanics behind the tool itself or how the tool is manufactured. A few articles Production Machining has published in the past discuss this topic.

Tool Life Means Spindle Utilization

It is this goal of keeping the machines running that Schwanog LLC (Elgin, Illinois) has set its sites on helping its customers accomplish. Since modifying its direction about 18 years ago to specialize in indexable form tools, the company has been increasing tool life and providing fast turnaround to help shops reduce machine downtime.

Putting More Teeth In Thread Whirling

When it comes to producing OD threads in difficult-to-machine metals, few processes are as fast or as efficient as the thread whirling process. Although the process is not new, its popularity is increasing because of the growing availability of thread whirling tooling for single-spindle Swiss screw machines that provides a relatively inexpensive alternative to investing in dedicated thread whirling machines.

German Form Tool Maker Opens U.S. Manufacturing Facility

Although this tooling manufacturer developed a loyal following in this country, many customers were reluctant to make major commitments to a firm whose manufacturing was located overseas. It became apparent to the company that to gain a larger share of the form tool market in this country, it would have to establish a manufacturing presence in the United States.

Serrating On The Lathe

If you are one of those firms doing serrating as a separate operation, you’ll be pleased to learn that there is now a serration shave tool that enables you to perform the serrating as just another operation on your CNC lathe.