Stama-America/Chiron America

10950 Withers Cove Park Dr.

Charlotte, NC 28278 US

stama-america.com

704-587-9526 simon.knecht@stama-america.com

AS SEEN IN PRODUCTION MACHINING

Do you have a new product or news release that should be included here for Stama-America/Chiron America? We'd love to include it! Send your content to our editorial team.

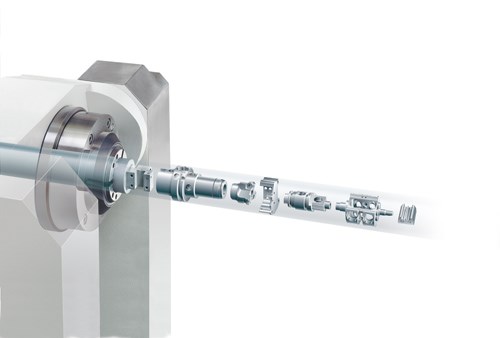

Are Bar Fed Machining Centers the Next Big Thing?

Advanced mill-turn machines with bar fed material handling can overcome several inherent weaknesses of production machining on vertical machining centers.

Product categories offered by Stama-America/Chiron America:

-

Drilling & Tapping

-

CNC Drilling & Tapping

-

-

Machining Cells & Systems

-

Machining Cells & FMS -

Machining Flex Lines

-

-

Machining Centers

-

Universal -

Vertical, Five-Axis -

Vertical, Up to Four-Axis

-

-

Milling & Boring Machines

-

Bed-Type Milling -

Universal Milling Machines

-

-

Services

-

Consulting -

Maintenance & Repair

-

-

Transfer Machines

-

In-Line -

Machining Flex Lines

-

-

Turning Machines & Lathes

-

CNC Turn/Mill Machines -

Horizontal CNC Turning -

Twin-Spindle/Twin-Turret Turning -

Vertical CNC Turning Centers

-

Trade Names offered by Stama-America/Chiron America

- STAMA

Is this Your Listing?

Connect with us to keep your company's information up to date.

.png;maxWidth=300;quality=90)