Editorial, News, and Products

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

Swiss Shop Turns Precision into Profit

The quality demands for micro-machined parts are swiftly increasing. Shops must be ready and willing to adjust their machining strategies to fit the need.

Tornos Hires Brian Glavanovits

Tornos hires applications and process engineer Brian Glavanovits

MedTech Demo Day, Oct. 10, Offers Latest Technologies, On-Site Evaluations

MedTech seminars, demos and promotions are available during the event.

Standardized Controls Aid Shop's Apprenticeship Program

Cox Manufacturing’s commitment to standardization, from the parts it makes to its machine controls and apprenticeship program, is an important factor in its growth.

PMPA Member Tornos Profile

The company particularly benefits from PMPA’s various conferences, including its National Technical Conference.

Tornos Celebrates 60 Years in U.S. with New Customer Center

Celebrating 60 years of service in the U.S., Tornos recently held a ribbon cutting ceremony and open house at its new Customer Center Chicago.

Tornos Technologies Showcases SwissNano at Grand Opening

Tornos Technologies US announces the grand opening of its Customer Center Chicago.

Tornos Technologies US Corp. Appoints New President

Daniel Maerklin has worked the past 14 years in the machine tool and metal-processing industries and brings strong leadership and market knowledge to Tornos.

Collaboration is Key When Implementing New Machine Tools

Working closely with builders can help shops ensure that new machine tools are a success.

Tornos Relocates Headquarters

On Oct. 29, Tornos moved to its U.S. headquarters from Lombard, Illinois, to Des Plaines, Illinois, in a new, 16,000 square-foot facility with a larger showroom that better serves customers.

SwissDeco Lathe Available in Range of Tooling Options

Drive technology, tooling, rigidity and modularity make Tornos' Swiss Deco line of Swiss-type lathes suitable for a range of industries.

SwissNano Manufactures Small Pieces with High Precision

The SwissNano machine’s kinematics enable turning, drilling, cutting, deburring, roughing and finishing operations.

Swiss-Type Lathe Helps Medical Shop Achieve Higher Precision

After the investment was made in a new Swiss-type lathe, not only was this company management’s expectations exceeded by the machine’s performance and efficiency, but the lathe is now included in plans for future applications.

Tornos Spotlights Century-Long Progression into Multitasking

At Tornos’ booth, the company is featuring No. 20, a Swiss-type lathe made in 1917, and visitors can assemble pens made from different Tornos machines, including SwissDeco 36 multitasking single-spindle lathe.

Turning Technology into Production

More and more, Swiss-type machine tool manufacturers are offering products that are flexible and affordable to job shops as well as large OEMs.

First-Class Manufacturing with Additive

Close attention to detail and automation of key processes is helping this shop earn its place as a leader in the 3D printing industry.

Homage to a Machine Tool Family Man

I thought it was worth sharing the following homage to a "machine tool man" because it speaks to the generational nature of the machine tool industry and how we tend to pay it forward.

Tornos Users can now Benefit from Mastercam Swiss CAM

Tornos customers using the company’s TISIS with ISO programming functions can now make use of Mastercam Swiss CAM to speed up programming on Tornos’ line of machine tools.

Tornos and Star CNC Showfloor Demos at PMTS

There are several education tracks available at this year’s edition, and on Thursday of the show, there are two more showfloor demonstrations that attendees can take advantage of.

Making Small Parts

It still amazes me how small some of the parts can be in our industry. Although it looks like it might be just a chip, this medical component has an 8-thousandths hole through it with four mills along the sides.

A Swiss Shop’s Next Generation

The shallow talent pool of available skilled machinists can be an even bigger obstacle to the shop that is rapidly growing. Perhaps the best solution is to attack the problem from within.

Sliding Headstock on Six Spindles

On my most recent trip to Europe, I visited the headquarters of Tornos in Moutier, Switzerland.

Finishing Touch

Tornos is not an everyday name in the surface finishing industry, but the company is well known as a machine tool builder, with some of the best machines in the world coming out of its European headquarters.

A Full Service Provider in Today's Economy

I’ve had discussions with many of our customers and other Swiss turning shops in recent weeks about how business is going, what they like or don’t like about their machines, and what concerns they have today and for their future.

A Multi-Spindle and Swiss Combination

At the recently completed EMO show in Hannover, Germany, the world’s machine tool and metalworking industry put on the biggest exposition on earth.

CNC Swiss Delivers in Many Ways

Designed to efficiently process long, slender parts for the watch industry, the Swiss-type screw machine has evolved well beyond its original application niche.

Qualifying for Medical Work: Advice from a da Vinci Shop

Swiss shop with heavy medical experience shares how to get and keep medical customers.

Bar Feeders Provide New Paths to Productivity

The lastest advances in bar feeding can help you prepare for the coming manufacturing resurgence.

Turn 1'' Barstock

The Sigma 20, a high-speed sliding headstock turning center, is designed with the flexibility required in a job shop environment. This machine can turn simple to moderately complex parts. The counterspindle is as powerful as the main spindle, allowing operators to perform simultaneous machining to minimize cycle times, the company says.

Swiss Shop Serves Medical And More

For more than 20 years this Chicagoland shop has been a supplier to one of the world’s largest manufacturers of medical devices. It’s a relationship that is built on mutual trust, consistent performance and a long-term view of the business of manufacturing. It’s also about properly applied technology.

Key U.S. Markets Need Parts

It’s pleasant to have a feeling of hopefulness at last after the dark days of the last few years. The American psyche was severely affected by 9/11, which devastated the financial markets and the economy in general. Not to say there isn’t that lingering sense of hurt, anger and fear. There is. But we are healing in spite of it and moving on.

Technical Member Profile: Tornos Technologies

Tornos Technologies is one of the world’s leading manufacturers of Swiss machine tools and automatic lathes. The company had its beginnings in the Swiss watch-making industry, which is known for its emphasis on superior mechanical precision.

OEM Recharges With Innovative Edge

You may have noticed a change in the way Tornos U.S. is operating. Since becoming president of Tornos U.S in June 2006, I have implemented sweeping changes that are at the heart of our drive for original thinking.

Making It Big In Small Parts

This New Hampshire manufacturer is an expert in manufacturing small, complex parts. Having a niche is one solid strategy for survival, but it takes dedication, focus and technology to pull it off.

Are You Medical OEM Material?

As the baby-boomer generation inexorably falls apart, screws, plates, rods and less invasive surgical tools are increasingly available to put "humpty" back together again. A question for many precision part makers is, "How do I get into the medical machining game?" To find out, we talked to a major OEM about its supplier selection criteria.

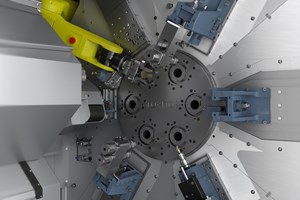

Meet The Multi-Center

How shops use the multi-spindle machine tool is changing. Complex workpieces, shorter production runs, rapid change-over and single part handling reflect the new reality of multi-spindle production. Builders are responding to these changing needs with new ways to make the multi-spindle machine more profitable, useful and efficient.

Thread Whirling On The Subspindle

The screw machine industry, not surprisingly, started out making screws. Then, screw machines were used to make almost everything but screws—electrical components, aerospace fasteners, plumbing connections and thousands of other kinds of parts.

A Different Way To Turn

The Esco concept turns turning 180 degrees. Unlike conventional lathes, the material, which is coil stock or bar from 0.02 mm to 12 mm, does not rotate. Stationary stock allows the use of round and profiled material.

Complex Angular Dental Implants...on Multi-Axis Automatic

Just like a car or a machine, the human body benefits from the technological progress of small parts turning equipment. Precision and stringent requirements for safety and stability are essential in the medical industry. In fact, the demands made on surgical screws (bone screws, maxillary-facial screws, implants and so on) and bio-implants can be much greater for the human body than for many industrial and commercial product applications.

Think You Can’t Afford New CNC Multi Technology?

At first glance, one might not think that spending hundreds of thousands of dollars on new CNC multi-spindle technology could actually improve a shop’s financial statement within several months, but it can and has at 64-year-old Kaddis Manufacturing in Rochester, New York.

Slashing Secondary Ops With New Swiss CNCs

This company employs 55 people. As labor costs have continued to grow, ownership has begun to realize that the only way to maintain profit margins is to become more efficient. Analyzing the operation, they've honed in on eliminating, or it least drastically reducing, secondary operations.

New Swiss Turning Technology Boosts Productivity For Contract Manufacturer

Technically, this control is not a CNC, but a PNC (parallel numerical control), and that is the difference. The PNC control was developed using a FANUC system that allows each machine axis to be governed by its own chip, which carries the part program.

Evolving From Conventional CNC To Advanced Swiss Technology

In 1999, this company and its management team started comparison shopping and decided to buy a this single spindle, Swiss-style CNC sliding headstock machine from their distributor. Now, the company says it can attract different types of work, especially high-precision jobs, because of the technology and versatility of this machine.

Evolving From Cam Multi-Spindles To CNC

There are thousands of cam-driven multi-spindles out in the field producing millions of parts 24 hours a day. And while there may always be a place for these machines when high volumes of relatively loose-tolerance parts are required, the tide is turning. CNC multi-spindles have emerged as a viable alternative now.