Tungaloy CBN Inserts Boost Productivity in Hard Part Turning

The company has upgraded its MiniForceTurn by introducing 30 new DXGQ/U0703 inserts with brazed CBN tips and an HP chipbreaker.

Sumitomo Turning Grade Provides Long Tool Life in Cast Iron Applications

The AC4125K turning grade is designed to lower overall tool usage and tool-change frequency while providing stable, long tool life in cast iron applications.

Seco Tools' Reamers Optimize Chip Evacuation

The Nanojet solid-carbide reamers are designed to stop chip jamming and enhance application stability.

Emuge-Franken Threading Tools Mill Challenging Materials

The company has expanded its offerings of solid-carbide thread mills with new products for challenging applications.

Sandvik Coromant Parting Tool Provides Improved Surface Quality

CoroCut QD Y-axis parting tools feature upgraded blades with no Y offset, providing easier programming and increased stroke.

Kyocera Turning Inserts Provide Fracture, Wear Resistance

The KBN010 high-speed CBN grade gives users more flexibility, range, performance and tool life when turning hardened materials.

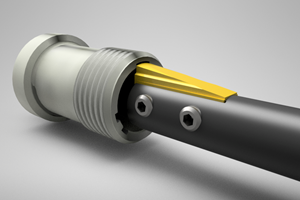

Tungaloy Boring Bar System Features Vibration Dampening

The BoreMeister boring bar system features a variety of exchangeable heads and shanks for internal turning, profiling, threading and grooving.

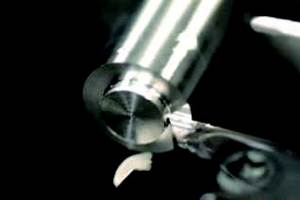

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Addressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

#techbrief #micromachining