Horn Toolholder Features Multiple Coolant Connections

The 224 grooving system features internal coolant supply that is fed directly to the insert via the clamping finger or directly to the flank face via a hole.

Piezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.

#Industry40

Monaghan Compensation Chucks Convert Standard ER Holders

Diatool ER Hydraulic Compensation Chucks enable users to convert standard ER holders to a repeatable, steerable hydraulic chuck for more precise machining.

Lyndex-Nikken Collet Chuck Increases Gripping Force

SK collet chucks enables for access to tight spaces and provides better clearance, making it ideal for machining complex parts.

Tungaloy Grooving Toolholders Provide Stable Turning

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

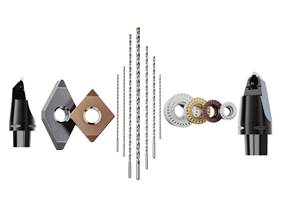

Seco Tooling Lineup Promotes Optimized Part Processing

The company’s expanded tooling lineup is aimed at applications ranging from general ISO turning to high-volume hard turning and deep-hole drilling.

Rego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Lyndex-Nikken Toolholders Offer Stable, Versatile Machining

Polygonal shank toolholders provide a rigid connection between the tool and machine — ideal for all processes both in turning and milling.

Big Daishowa Toolholder Increases Precision for Lathes

The Big Capto C3 series provides higher rigidity to minimize vibrations and movement during cutting, improving accuracy and efficiency.

Tips for Choosing the Right Toolholder for High-Speed Machining

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

#techbrief