Keeping Current with the Medical Machining Market

The medical machining industry being supplied by the precision machined parts industry is changing. This Northeast Ohio shop is working to keep up with the need to serve changing requirements of its medical customers by increasing the shop’s operational capabilities.

Hybrid Multi-Tasking Machine Includes Five-Axis Capability

Mazak’s VC-500 AM hybrid multi-tasking machine includes additive and subtractive part processing and full five-axis capability, both features that help shops reduce time to market and cut R&D costs.

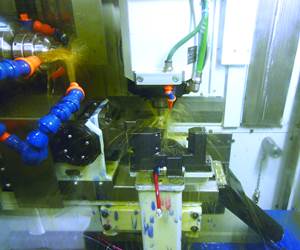

Split-Slide Lathe Cuts Parts with Three Cutting Tools

Tsugami/Rem Sales’ BW129Z is a 12-mm, nine-axis split-slide lathe, with a simultaneous three-path control system and dual independent gang slides, that can house 28 tools and is equipped with a FANUC 31i-B CNC.

TNC 640 Mill-Turn has a 3D Probing Cycle Option

Heidenhain’s TNC 640 mill-turn has a 3D probing cycle option called Cycle 444 to meet increased requirements for automation and advanced probing routines that inspect free form surfaces where measurement positions are often difficult to capture.

Puma V8300 Heavy-Duty Vertical Turning Center Features ATC

Doosan Machine Tools’s Puma V8300 15” class vertical turning center has an automatic toolchanger (ATC), a larger workzone, increased rigidity and enhanced user convenience and is available in right- or left-hand versions.

#horizontal-and-vertical-lathes

Multitasking Takes a Turn

Turn-mill machines are known for their capabilities in single-setup part production. Here are two very different examples of shops that are using multitasking to their advantage in medical machining.

Colchester MultiTurn CNC Lathe Increases Versatility

600 UK’s Colchester MultiTurn two-axis manual/CNC lathe is a flat-bed CNC lathe that incorporates the Siemens 828D control with Shopturn as a standard feature, although FANUC 0iTF with Manual Guide can also be fitted.

Moving Vertical Turning Up

There is always room for improvement, and transitioning from vertical turning to inverted vertical turning can be one way to improve your shop’s efficiency. The benefits of inverted vertical turning include a smaller machine footprint relative to horizontal turning centers of similar capacity; multitasking capabilities; and maybe the biggest benefit—chips fall away from the spindle into a conveyor in the machine base and out of the workzone.

#basics #horizontal-and-vertical-lathes

Two New Twists on Thread Whirling

Thread whirling as a metalworking process dates to the 1940s. Recently, developments in production speeds, based on this increasingly popular process, are impacting thread manufacturers.

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

#basics

.JPG;maxWidth=385;maxWidth=300;quality=70)