Video: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

#techbrief #Industry40

Video Tech Brief: CNC Screw Machines a Solution for Overcoming Labor Shortages

CNC screw machines can exceed job shop productivity and enable manufacturers to overcome perpetual employment gaps.

#workforcedevelopment

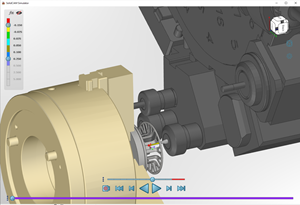

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

#basics #horizontal-and-vertical-lathes

Bridging the Gap Between Traditional Single- and Multi-Spindles

This twin-spindle automatic lathe with six cross-slide mounted turrets is designed for medium-sized production runs that might not be suitable for conventional multi-spindles.

#techbrief

How Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

Video: Machine Shop President Explains Advantages of Tool Presetters

When contract shop MetalQuest purchased its first multi-spindle, it also purchased a dedicated tool presetter for the machine. Learn why the company president feels shops of all sizes can benefit from measuring tools offline.

Why a CNC Multi-Spindle Machining Center Makes Sense for MetalQuest

An early adopter of multitasking equipment, this Nebraska contract manufacturer has taken what it feels is the next logical step to diversify by adding a multi-spindle for greatly reduced cycle times on an existing high-volume job.

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

Turning Toward The Future

This new machine tool represents the lastest in a new generation of CNC multi-spindle automatics. Its development was a clean sheet approach and the results are impressive.

.png;maxWidth=970;quality=90)