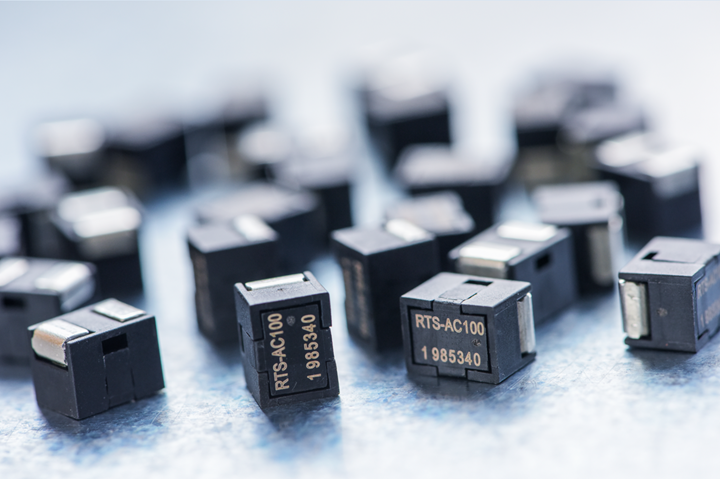

As the trend toward electromobility gathers speed, electric fuses are taking on a key role, especially in the production of batteries for electric automobiles. The fuses consist of numerous small parts, which must be made in large quantities. Each battery cell requires individual fuse protection, so the total number of fuses in a vehicle can quickly reach 400 or 500. Combined with the strict standards of the automotive industry, these parts can be difficult to produce and test.

The fuses’ spring force is tested in the first station at the automated plant (center right). Another sensor performs a cross-check about once in every 100 parts (front left).

Electronics and electrical components such as fuses, connectors, switches and circuit breakers are one of the cornerstones of Schurter’s portfolio. The Lucerne, Switzerland-based company also produces input systems such as human-machine interfaces, touch panels and membrane keypads. In recent years, Schurter has added custom solutions based on a high level of vertical integration in its Solutions division.

Schurter has ambitious plans for its future. With a workforce that is already 2,000 employees, 11 production facilities and companies in 17 countries, the company has set the stage for growth to continue. Acquisitions are adding momentum; sales amounted to 259 million Swiss Fancs in 2017, and the trend is upwards.

A customer in the automotive industry commissioned Schurter to produce small fuses. These fuses are made in large quantities (3,000 per hour) and must be tested for use in safety critical areas.

In 2017, a customer in the automotive sector commissioned Schurter to produce large quantities of fuses for use in safety-critical areas. "We can draw on many years of experience in automating fuse production processes. And thanks to our technological edge, we're still able to carry out the development work here in Switzerland, as well as some of the production,” explains André Schürmann, head of automation and maintenance at Schurter. “That's something our customers really appreciate."

The fuses must be manufactured using as much automation as possible, in compliance with standards and quality. To meet these exceptional challenges, Schurter invited its neighbor to come on board—special-purpose machinery manufacturer Robomat AG. "Robomat presented us with a detailed offer for the development of the plant, including a 3D layout and exact pricing,” Mr. Schürmann says. “Combined with their physical proximity and the close working relationship that developed from day one, this added up to a highly convincing complete package."

High-Precision Testing in Seconds

According to Markus Zimmermann, owner and CEO of Robomat, the project is complex. "Two fuse variants are produced on this plant, at rates of about 3,000 parts per hour and with a cycle time of 2.7 seconds. The product passes through 16 different stations in that brief period of time. Designing the plant faced us with the challenge of coordinating the process steps so as to achieve the short cycle time,” he says. “The beauty of it was that Schurter hadn't yet finalized the fuse design when we started work. This meant that special requirements could still be incorporated into the design. Of course, that's only possible if you're close enough to the customer," he stresses.

Kistler's force-displacement monitoring systems were chosen to meet the demanding requirements for traceability and quality in the automotive industry. A total of four Type 9217A piezoelectric small force sensors with matching maXYmos BL evaluation systems are deployed in the new plant. "As well as our favorable experience in the past, the main factors that persuaded us to opt for Kistler were the small force range and the very low response threshold," Mr. Zimmermann notes. The measured key variables are recorded and visualized during the process. In addition, the defined criteria are used for automatic in-process segregation of good and bad parts. Testing includes the spring force as well as the force applied to position the covers on the fuses.

The sensors themselves are also tested. "What's really special about this plant is that the measurement equipment itself is cross-checked during the actual process. The sensor technology is measured about once in every 100 parts—to verify whether the sensors are still capturing the data that they should," Mr. Zimmermann says. "This development is driven by requirements in the automotive industry,” Mr. Schürmann adds. “According to the International Automotive Task Force's standard IATF 16949 for safety-critical parts, the capability of the measuring equipment has to be verified regularly during the production process. The end customer specifically audited this particular point here in our plant."

Four Kistler maXYmos BL process monitoring systems are installed in the plant.

The combination of the customer’s specifications, compliance with standards and the highly complex plant means that the company can attain a high level of quality data. "For each fuse, 76 specific datasets are captured and stored in one central database – as well as force and displacement, the data covers many other variables such as furnace and air temperature. This is the most extensive acquisition of quality data that we have ever implemented on one plant," Mr. Zimmermann notes. Now that Schurter and Robomat have met all the specified requirements for quality assurance and documentation, the two companies can focus on optimizing the operation of the plant.

Intuitive Measurement Technology Generates Added Value

There is still some way to go before series production can finally begin. Although the end customer gave approval after about a year of development work, the plant has still not reached the 24/7 volume production that Schurter is targeting. Phase two is focusing on intensive testing and optimization of critical factors such as materials, plant settings and other parameters. "The measurement technology didn't need very much effort because the systems can be operated intuitively," Mr. Schürmann says. "We've already used Kistler products in the past, so we know we can rely on performance, service and value for money," Mr. Zimmermann adds. "But other parts of the plant are so complex that commissioning and optimization involve a substantial workload. Once the target has been attained, the settings are transferred directly to a second plant so we can cover the planned high quantities," he continues. The maXYmos systems, along with the rest of Kistler's technology, will be on board at that stage, with double testing to ensure that the fuses keep their promises.

Markus Zimmermann, owner and CEO of Robomat, André Schürmann, head of automation and maintenance at Schurter, and André Signer, sales engineer at Kistler worked together to develop a system to produce and test electrical fuses.

"We appreciate the excellent collaboration, the professional support and Kistler's close relationships with its customers—and we shall be glad to choose Kistler again in the future," Mr. Zimmermann concludes.

"Plants will have to become more and more intelligent to meet the challenges posed by e-mobility and Industry 4.0. Condition monitoring, predictive maintenance and batch-level traceability are increasingly becoming part of the standard,” Mr. Schürmann adds. “This calls for measurement technology that can be integrated easily and operated intuitively – and it has to deliver precise and reliable results. In-process quality monitoring definitely generates added productive value, which is why growing numbers of industrial manufacturers are integrating it into their production."

Schurter Inc. | 707-636-3000 | us.schurter.com

Kistler Instrument Corp. | 248-668-6900 | kistler.com

Related Content

Precision Machining Technology Review December 2022: Measurement

Production Machining’s December measurement showcase includes some of the latest technology from Haimer, Hamar, Sunnen, OGP, Marposs and Zeiss.

Read MorePrecision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

Read MoreHow Well do You Know Granite Surface Plates?

Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs.

Read MoreVideo Tech Brief: Quality Control is Using the Right Software

This machine shop’s mapping software program runs on its gaging system to increase the accuracy of the probe’s tolerance measurement on the thin-walled aluminum tube machined by the shop.

Read MoreRead Next

Inspection System Helps Company Meet Short Lead Times

A digital video inspection system from Starrett is increasing this company’s inspection throughput and helping it get parts to its customer on time.

Read MoreAutomated Inspection on the Shop Floor

Most machine shops understand the value of automation when it is applied to such operations as turning, milling and grinding.

Read MoreAvoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read More