Hexagon’s Surfcam 2021 Connects Directly to Advanced Machining Simulation

Direct link gives manufacturers greater control over manufacturing process by delivering a more accurate, detailed picture of each machining operation from start to finish.

Surfcam 2021

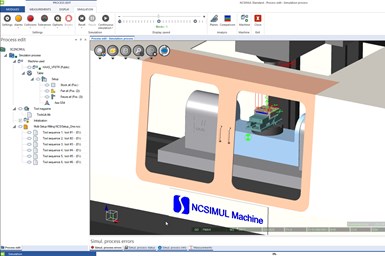

The newest version of Surfcam Traditional CAM software offers a direct connection to the NCSIMUL machining simulation solution by Hexagon Manufacturing Intelligence. This development is said to give Surfcam programmers greater control over the manufacturing process by delivering a more accurate, detailed picture of each machining operation from start to finish.

The software is designed to provide manufacturers with robust, flexible and easy-to-use programming capabilities for 2-5-axis machining, as well as turning and wire-EDM programming functions. NCSIMUL machining simulation software can be used in conjunction with a wide range of CAM systems to verify and optimize toolpaths, quickly switch NC programs between machine tools and simulate machining operations.

By using a direct link to NCSIMUL from within the Surfcam interface, users will have access to true G-code toolpath verification, editing and simulation functions to ensure that NC programs are collision free and reflect the full CNC machining environment. This new associativity between the two systems also enables users to compare cut stock with original design geometry. The ability to view the state of the stock model throughout the machining process (including multiple operation parts or multiple parts setup) gives machinists the flexibility to adjust operations, when required, to prevent errors.

Users can access NCSIMUL via the system’s operations manager, which lists setups for operations in the order they’ll be performed, as well as relevant machining data for each operation. From there, users can view the part within the NCSIMUL interface in various modes, including wireframe, facet, shading and shape modes. Tooling, tooling sequences and tool paths can be viewed and edited within that same interface. The direct link to NCSIMUL also enables users to digitally add or subtract part stock and adjust fixturing, clamps and cutting tool libraries. Access to detailed virtual setups removes guesswork by providing accurate digital twins of complete machining environments that can then be recreated in the real world.

Related Content

-

Mastercam Software Improves Programming Flexibility

IMTS 2024: Mastercam introduces Mastercam 2025, with features including Mastercam Deburr for automated edge finishing, finish passes, mill-turn support for Y-axis turning and automatic license update notifications.

-

Lone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

-

Who Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.