A Leaner Shop With CNC

It was a tough decision, but once this company moved forward with the implementation of CNC, it quickly realized the benefits in production times, tolerances and finishes. Most important, though, was the added secondary-op capabilities that brought consistency to the personnel requirements of the shop.

Alfonso Garcia was not easily swayed. After all, he had been with the company for 20 years—10 as company president—and he had become quite accustomed to the unpredictable nature of the business, the constant personnel changes and the struggle to meet customer deadlines. He couldn’t see how incorporating CNC could alleviate the burning issues, and he couldn’t justify the cost or the time it would take to bring one of these machines into the mix. In fact, the pressures of deadlines were so immense, he couldn’t take the time to consider the possibilities.

Rite-On Screw Products Inc. (Irwindale, California) opened its doors in 1970 with two Brown & Sharpe 00G screw machines and two 2Gs. By 2005, it had amassed 18 Brown & Sharpes along with several Bridgeports and four Hardinge lathes for secondary operations. The shop was producing typical single-spindle work, mainly from brass and stainless, including parts for aerospace, medical, marine products and commercial appliance applications.

The work continued to come in through the years, and business was pretty good, according to Alfonso, but the inconsistent need for secondary operations caused constant issues in managing the number of personnel. “If the right jobs came in, we needed as many as 18 people on the floor to keep all of the machines running and get the product out the door,” he explains. “But if all we had was long-run work suited for the single-spindle automatics, we were forced to lay five or six people off rather than pay them to be doing nothing. When other jobs requiring secondary operations would come in later, we’d have to scramble to bring additional operators back in. Of course, the ones we had let go were usually no longer available, so we’d face still more challenges of finding quality employees and training.”

In 2004, Mike Colby, of Represents West (an independent sales representative for Ganesh Machinery), made his first call to Rite-On—a cold call that was not welcomed with open arms by Mr. Garcia. During the brief meeting, Mr. Colby tried to explain the benefits CNC could bring to the shop, but Mr. Garcia quickly dismissed him, saying, “We cannot increase our cycle time by taking in CNC lathes.”

About a year later, Mr. Garcia hired his brother, Raymond, to handle accounts and to get involved in the day-to-day operations of the shop. Mr. Colby had been persistent in his efforts to explain to Alfonso that CNC machines would prove to be the key to Rite-On’s continued growth. Raymond was a recent college graduate and had a solid background in computers, so Alfonso thought he could provide a fair analysis of the machines’ potential at their shop.

After further discussions, Alfonso was able to get a sense for how the additional capabilities of the CNC machines could help the company. He put together a business plan to bring in the first Ganesh machine, a four-axis CNC turn/mill center. The shop floor was already overcrowded with Brown & Sharpe machines and storage for the backlog of parts awaiting secondary operations, so Alfonso had the storage facility next door wired for the machine. “We did not feel that we could afford to stop production and take down any old machines to install the new one,” he explains. They still weren’t quite sure what they were getting into and worried that the machines would not come through as expected. “Mike told us the cycle times were quick, but we were already putting a lot of trust in someone who stood to benefit from the sale of the machine.” So they made the move as conservatively as possible, keeping the option open to fall back on the older machines if necessary.

Gary Walts, the Ganesh trainer, needed only 2 days at the Rite-On facility to show Raymond how to get the most out of the machine. From there, Raymond was able to immediately start working through the secondary operation work that had accumulated. The results were remarkable.

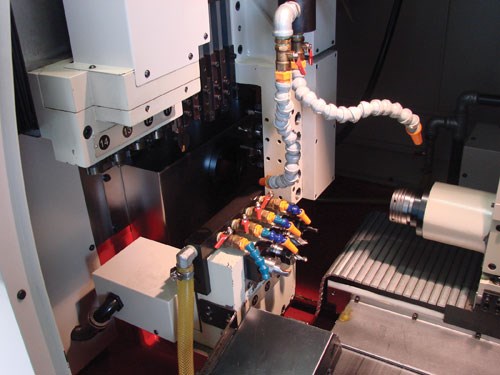

Within a matter of months, Rite-On began considering a second CNC machine. Alfonso and Raymond had quickly realized the consistency the step up to CNC had brought to the business, so they purchased a Cyclone 32 three-axis gang tool lathe with optional live tools. Less than a year later came the biggest commitment to CNC. Rite-On removed ten of its conventional machines, moved the Ganesh machines into the main facility and purchased yet another—a seven-axis dual-spindle mill/turn center.

Clearly the addition of CNC machines has been the turning point in Rite-On’s business. It has saved the company a lot of time and money and opened the door for new business. “Faster production, tighter tolerances and better finishes have been a great side benefit,” says Raymond. “Often overlooked in screw machine houses is the amount of time that goes into handling the part. The obvious measure is the time the machine is engaged in the metal, and a Brown & Sharpe can often knock off a part in a matter of seconds. But what about the secondary operations and the time it takes to pull the part out of the bucket and degrease and clean it before it’s ready for the next operation? It is handled multiple times, often requiring cleaning after three different operations. Being able to cut back on that time and those expenses is huge.”

But the main reason the company purchased the machines was to deal with the issue of labor. And that problem has certainly ironed itself out. Only seven employees now handle the workload that needed 18 people in the past. No longer do Raymond and Alfonso need to lay off employees when business slows down and then scramble to hire again later. And they are no longer reliant on the high-volume work that the Brown & Sharpes are so well suited for. Raymond explains, “We had gotten to a point where our profit margin was diminishing by costs related to re-hiring, training and excess handling. Now, the savings we’ve realized by carrying ten less employees for a year is roughly in line with the cost of all three of the CNC machines we purchased. And we’re far more productive and are able to take on work that we couldn’t produce before.”

— Expand Machinery

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreCAM-Driven Lathe Questions

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

Read MoreLaser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read More5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

Read MoreRead Next

Shop Jumps Into CNC Machining

Although this shop was already established and highly successful, it recently decided to make the "jump" into CNC machines, acquiring three new machines.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More