5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

#basics #techbrief

Many precision machine shops benefit from multitasking machines, some having multiple turrets and spindles, on their shop floors. The challenge is programming these complex machines.

Many precision machine shops benefit from multitasking machines (some having multiple turrets and spindles) on their shop floors. While these complex machine tools often lead to invaluable advantages — such as reduction in part costs, floor space and setup, increased part accuracy and throughput, unattended operation, the ability to machine parts complete and more — complicated CNC programming presents challenges. Hence, the process usually requires more experienced programmers.

To help simplify the steps for creating the most effective and accurate program, Chris Pollack, international business development manager at Siemens Industry Inc., offers five general tips for multichannel programming. Although Pollack refers to Sinumerik controls to explain some points, these tips are useful on any multitasking CNC, not only on Siemens controls.

Featured Content

1. Have a defined datum reference from which to build. Most machine tool OEMs reference their datum from the face of the main spindle, according to Pollack. Knowing this simple fact and using that point as the reference for building the program will make the process much easier. When programmers start with a random point within the machine, it makes programming the nesting of parts and transferring parts from the main to the subspindle much more difficult, he explains.

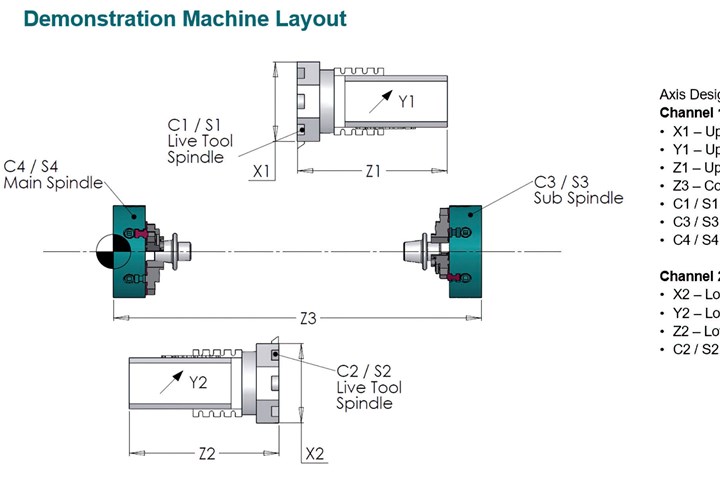

2. Create a cheat sheet that assigns channels to axes. Attempting to remember all the axes inside multichannel machines can be difficult.

Therefore, making a cheat sheet that labels the axes and taping that sheet to the front of the machine can provide a reference for both the programmer and the operator. This is especially useful for operators who move from machine to machine on the shop floor because each machine tool OEM can label its axes differently. Pollack also suggests laminating the information sheet.

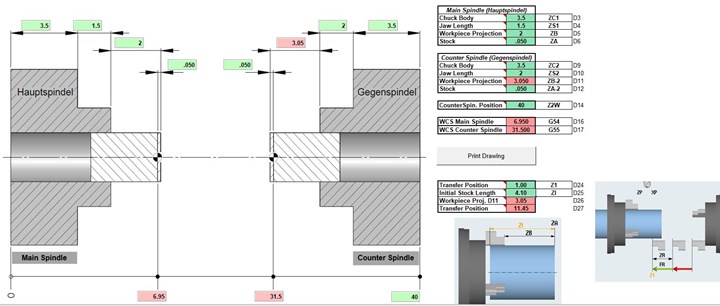

3. Sketch drawings of a specific job’s layout prior to programming. Pollack says he draws the layout of a particular job on a scratch pad. The sketch includes basic block drawings of the part sitting inside the chuck, how far it projects from the workholding, the transfer and where it will end up in the machine. “If you take a few minutes at the front end of the job to figure out the layout, it makes everything much simpler,” he explains. “If you don’t do this, you quickly lose where you are in the space.”

Using this Excel spreadsheet that generates the machine parameters and offsets simplifies the programming process and takes away any guesswork. Photo Credit: Siemens Industry Inc.

Using an Excel spreadsheet that generates the machine parameters and offsets also simplifies the process and takes away any guesswork. Pollack and a colleague created a spreadsheet that enables users to plug in measurements.

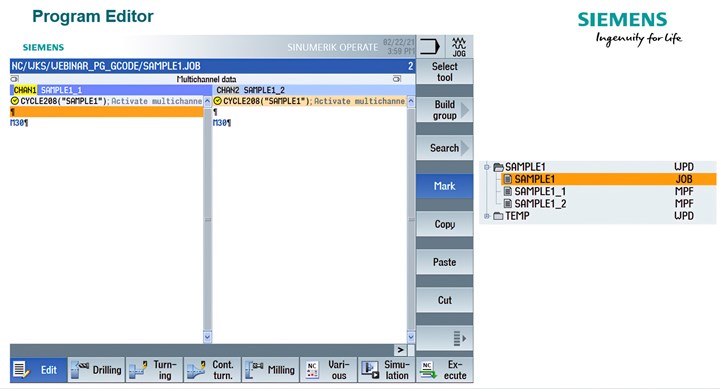

4. Use the simplest interface to manage the programs and their specific channels. Sometimes there are two part programs on the CNC, and it is often up to the operator to know which part program is going to run in the correct channel. However, the operator might not know, becomes confused and loads the wrong program into the wrong channel. This mistake can be catastrophic. To avoid this problem, Pollack suggests designing functions into the system that make machine operation unambiguous and more user-friendly.

For example, Siemens Sinumerik CNCs offer a function in the sync multichannel programming called the Job List. When the programmer creates the job file, he/she then tells it which program belongs in which channel. This option can be available in the CAM program as well as for shopfloor programming. “Even if you are programming it all in CAM, you can still have the CAM package output the job files and then output the corresponding programs for each channel and the job file,” Pollack explains.

When loading the program into memory, this function will open a Master Editor and load each program into the corresponding channel. Therefore, the programmer can modify part programs simultaneously on one screen, instead of jumping between the upper and lower turret program windows.

With Master Editor, the programmer can modify part programs simultaneously on one screen, instead of jumping between the upper and lower turret program windows. Photo Credit: Siemens Industry Inc.

Most important with this functionality, however, is when the programmer clicks “Execute,” the software automatically loads the appropriate programs in the appropriate channels. Therefore, the operator never has to think about whether the program will run accurately; he/she simply opens the job file.

5. Use wait commands. When there is a program running in the machine’s upper and lower turret simultaneously, wait commands can be added so that one turret waits for the other one to finish. The wait commands enable an operator to pause the machine.

“As you start to get more and more of these commands in, it can be confusing,” Pollack explains. “At what point in time is my upper turret waiting for my lower turret or vice versa?”

He says Sinumerik has functionality in its Editor called Sync View. By choosing Sync View, the program aligns all the wait commands so an operator can see exactly which operation is aligned with which part. Without this function, wait times are listed pages away from each other in the program. Pollack says this can be beneficial because if the operator does not know exactly what part is waiting for what process, he/she can get confused.

“Even if you are not using a Siemens system, look for a third-party editor that has this type of capability,” he adds.

Siemens Industry Inc. | usa.siemens.com/cnc4you

RELATED CONTENT

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.