Tips for Choosing the Right Toolholder for High-Speed Machining

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

#techbrief

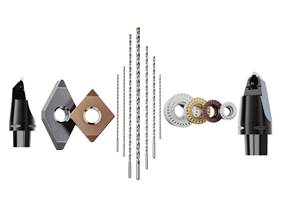

Lyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

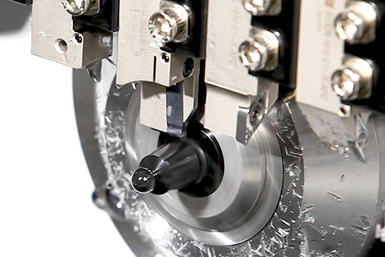

Horn Toolholder Features Multiple Coolant Connections

The 224 grooving system features internal coolant supply that is fed directly to the insert via the clamping finger or directly to the flank face via a hole.

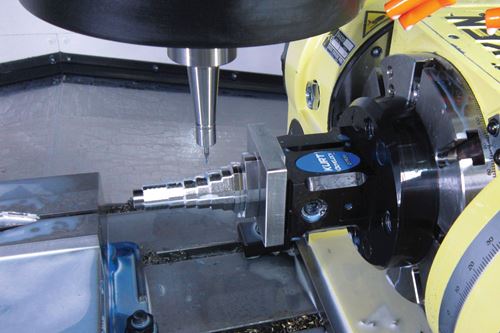

Monaghan Compensation Chucks Convert Standard ER Holders

Diatool ER Hydraulic Compensation Chucks enable users to convert standard ER holders to a repeatable, steerable hydraulic chuck for more precise machining.

.png;maxWidth=970;quality=90)