When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

#basics

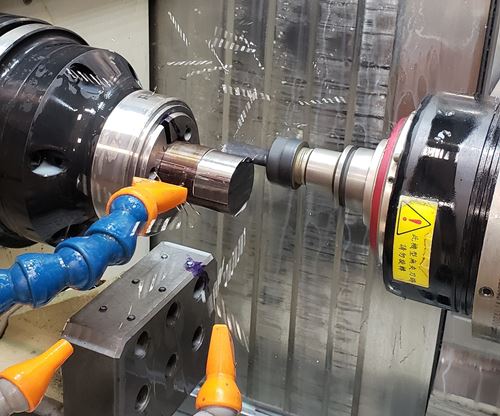

Absolute Machine Tools Turning Center Provides Improved Chip Removal

Johnford SL-300L-II slant-bed turning centers are constructed with a one-piece Meehanite cast iron base for strength and rigidity, as well as to dissipate heat away from the part.

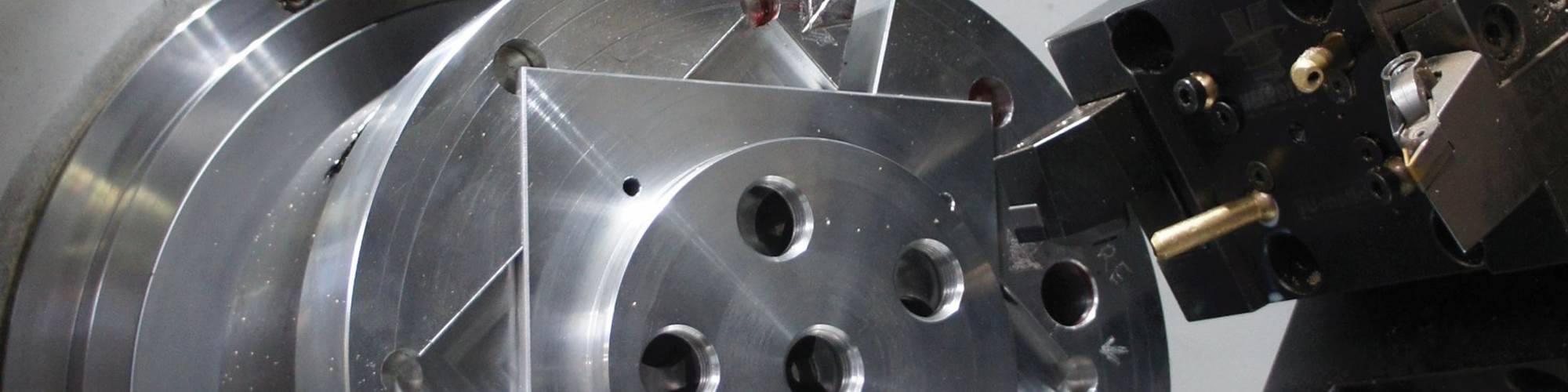

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

#techbrief

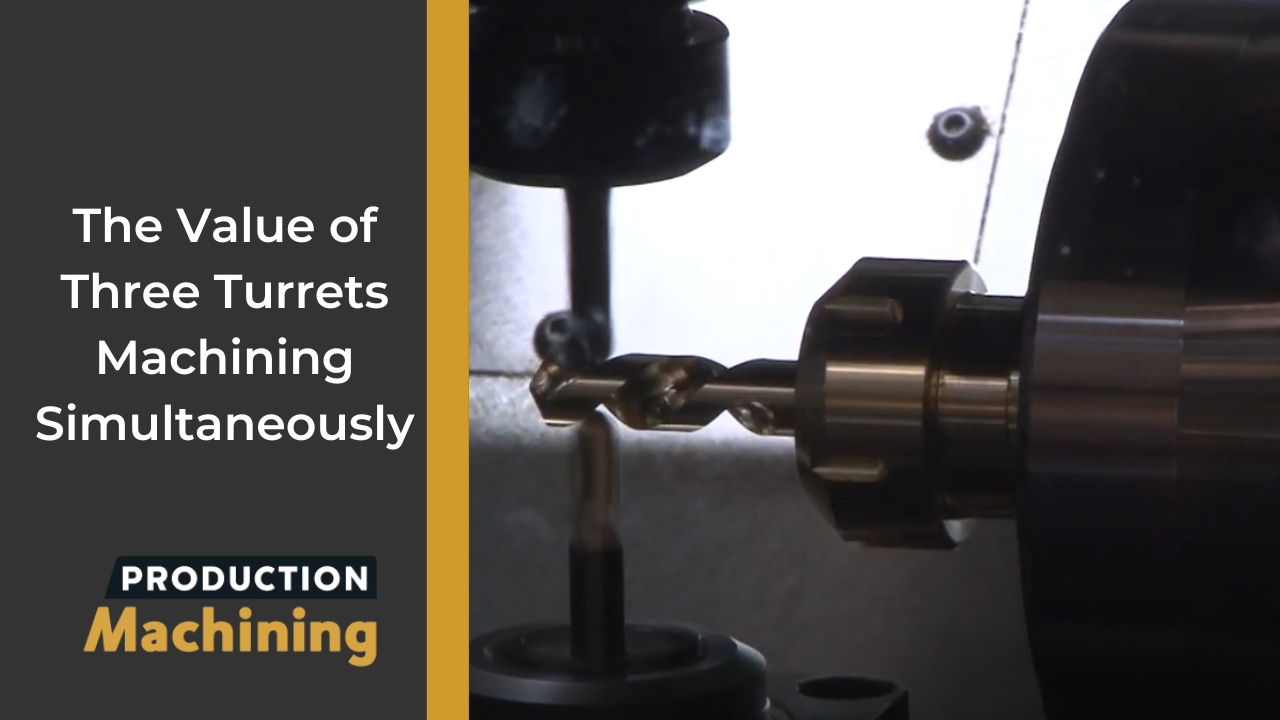

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

#micromachining