At first thought, seeing how additive manufacturing fits into the shop of the typical Production Machining reader may be difficult. But as our readers begin expanding the capabilities of their shops, it is natural for them to consider additive manufacturing. Although this technology is still relatively new to the machine shop, it is promising and has been generating a lot of interest.

To find out how additive manufacturing could work with precision turning, we reached out to Eric Miller, co-owner and principal of Phoenix Analysis & Design Technologies Inc. (PADT), which provides a range of additive manufacturing equipment, services and support. From our conversation, it became clear that 3D printers will not be replacing lathes any time soon. Nevertheless, there are several reasons to understand and start exploring this technology.

Featured Content

For starters, customers are likely thinking about it and talking about it. “They want to make sure they’re not missing something,” Mr. Miller says. Even if additive manufacturing is not a good fit for a customers’ needs, shops need to be able to confidently explain why. “Knowing when AM is and isn’t a good fit is a competitive advantage for a shop,” he says.

And even though they may not be numerous right now, there are circumstances in which additive manufacturing can complement turning. Mr. Miller says the need for these applications is growing and presents big opportunities for the precision turning industry.

Another reason to look at additive manufacturing technology now is that it could soon advance to the point where it will be a better complement to precision turning. According to Mr. Miller, systems that will increase AM’s productivity, as well as make it cheaper and easier to implement, are currently in development.

What is Additive Manufacturing?

According to Mr. Miller, a good first step to exploring additive manufacturing is adopting the right mindset about the technology. “Don’t treat AM as different,” he says. “It’s just another machine tool.” Like every other machine tool, it requires materials, it needs to be programmed, and many of the parts that come out of a machine need post processing. “It’s just a different way of making a part,” he adds.

There are two main types of materials used in additive manufacturing: polymer and metal. Each has different strengths, weaknesses and uses, especially when it comes to how they are used in combination with turning processes:

Polymer. Polymer (or plastic) AM can produce parts that cannot be made by traditional machining processes, such as complex internal features in medical implants. It can also produce one-off parts quickly. In addition, these systems tend to be easy to program and can be run without much training or special expertise. However, accuracy and surface finish can be a challenge, and the technology is only cost-effective for producing small volumes of parts.

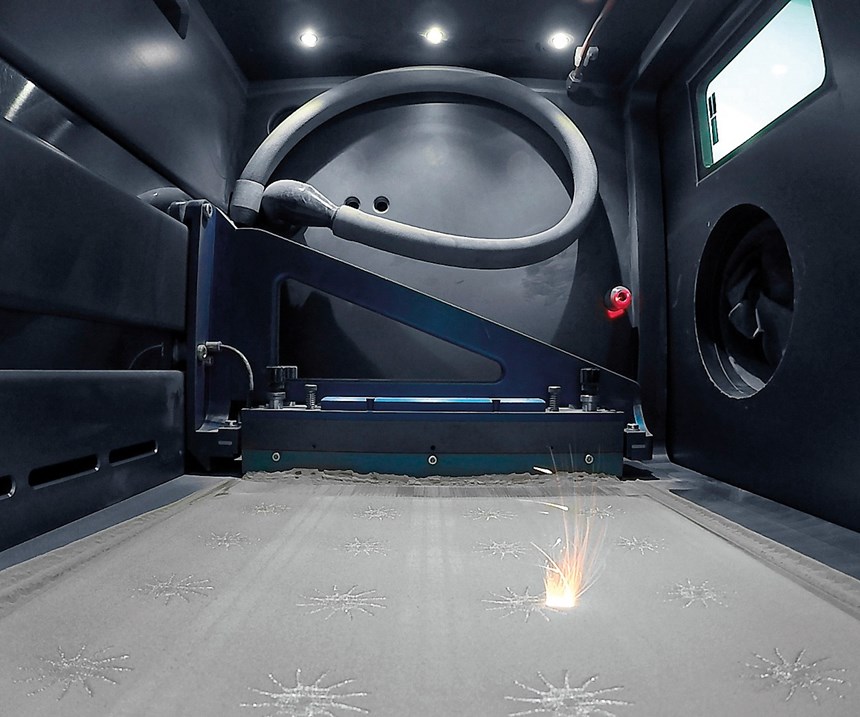

Metal. Metal 3D printing can also produce parts with features that cannot be machined. Like polymer 3D printers, metal 3D printers struggle with accuracy and surface finish. In addition, they are expensive (capital equipment and infrastructure costs are currently between $300,000 and $1.2 million, according to Mr. Miller) and often require special expertise (such as metallurgy), which makes them difficult to implement. Shops also need to consider the material properties of 3D-printed metal parts. Metal 3D-printed parts may be able to replace castings, but the technology cannot replicate the material properties of forgings.

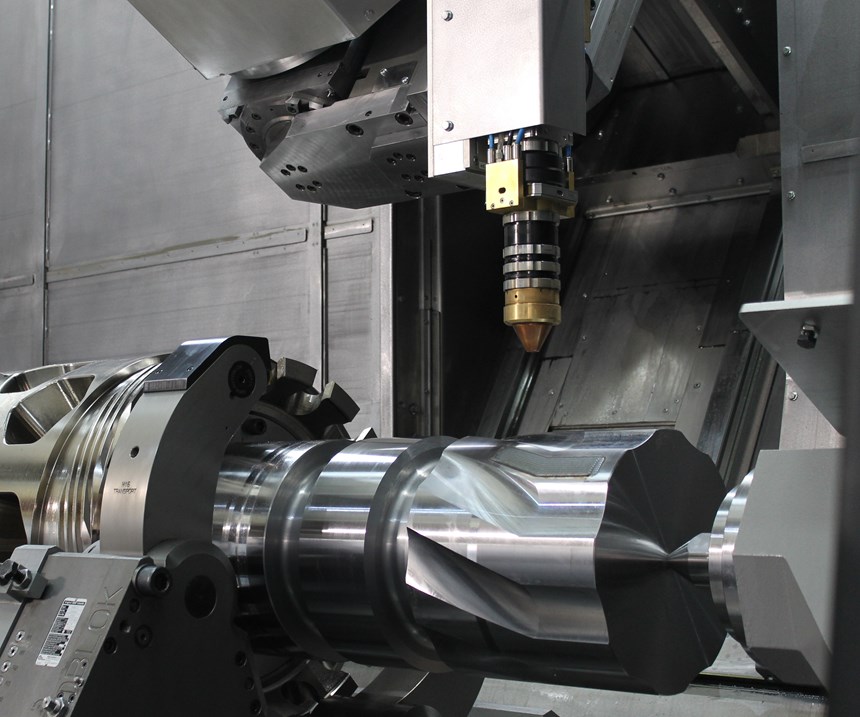

Metal additive manufacturing can also be combined with traditional, subtractive machining methods. Hybrid manufacturing systems are CNC machines (usually multitasking or milling machines) with metal deposition heads. This design gives them the ability to both add and remove stock within the same machine.

How to Use AM

According to Mr. Miller, there are several ways shops that focus primarily on turning could use or encounter additive manufacturing:

Tooling and fixturing. For polymer 3D printing, Mr. Miller says the number one use in the machining space is tooling. Although turning does not require the complicated tooling and fixturing of milling, additive manufacturing can still prove useful. For example, a shop could 3D print a plastic sleeve to protect delicate parts from being damaged by the chuck as they are being turned. The sleeve fits around the part, and both go into the chuck.

Designs and prototypes. Polymer AM is also well-suited for design and prototyping. For shops that do a lot of up-front prototyping, buying a 3D printer and doing the work in house could be more cost-effective than outsourcing the work. Polymer 3D printing offers a quick turnaround on prototypes, which can be used to determine form, fit and possibly function. “You can make sure the parts are good before you go to machining and make 300 or 3,000 of them,” Mr. Miller says. He adds that 3D printing can help speed the design process for design engineers. “Advanced rendering capabilities allow us to visualize work on a computer screen quite well these days, but there’s nothing like holding it in your hand and putting the parts together to see if they fit,” he says.

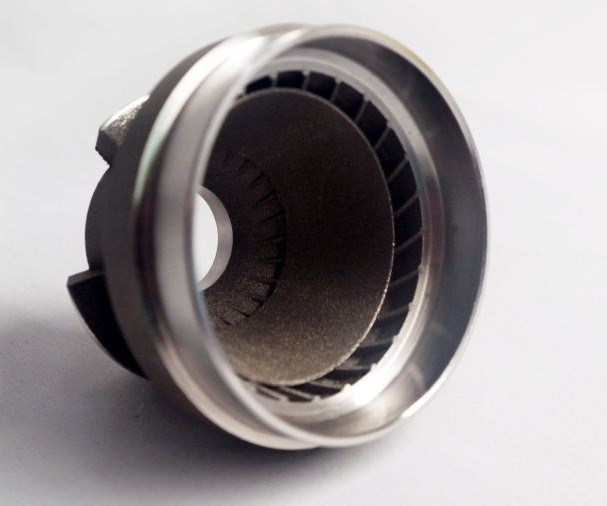

Replacing metal castings and weldments. Metal AM can be used instead of a number of different processes for producing parts. For example, injector nozzles that in the past were made of several parts welded together can now be 3D printed as one part. Castings are also being replaced with metal additively manufactured parts. When these parts come out of the 3D printer, they require additional work. “We can’t 3D print really highly accurate surfaces,” Mr. Miller says. “We still have to machine those critical surfaces.” Understanding additive manufacturing technology, as well as its strengths and weaknesses will help shops perform these machining operations. Mr. Miller sees this as a key area of growth and a big opportunity for shops. For shops that do perform these operations, he adds that it is helpful for them to consider 3D printing as part of their upstream process.

Producing parts that can’t be machined. Possibly the biggest advantage of additive manufacturing is that it can be used to produce parts that cannot be machined. Aerospace parts and medical implants with complex internal features, for example, can be 3D printed in either metal or plastic. These parts must then be brought into tolerance using machining methods such as turning.

Repairing parts. According to Mr. Miller, hybrid manufacturing systems are mostly used for repair. The additive manufacturing capabilities of these systems are used to add stock to damaged parts, which can then be turned in the same machine to be brought into tolerance.

Where to Start

With so many different types of technologies, systems, brands and materials, shops that want to begin incorporating additive manufacturing into their operations might have a difficult time knowing where to start. Mr. Miller offers these suggestions:

Outsource metal AM. Because of the cost and expertise required, Mr. Miller recommends that shops initially outsource metal 3D printing. “Let the experts be the experts,” he says. Then, when the volume picks up, shops can re-evaluate whether it makes sense financially to bring that process in house.

Purchase an FDM 3D printer. According to Mr. Miller, polymer additive manufacturing systems can easily be brought in house and do not require a lot of special knowledge to operate. He says that of the different polymer 3D printing technologies available, fused deposition modeling (FDM) systems are the easiest to get up and running. These systems use filaments of plastic materials, which are extruded through a heated nozzle onto the print bed to form the workpiece in layers. These systems are also sometimes called fused filament fabrication (FFF) or material extrusion. When choosing an FDM 3D printer, Mr. Miller cautions shops to avoid using inexpensive desktop machines for professional work. “The quality is just not there, and you’ll spend more time fiddling with it and trying to get it to work,” he says. He recommends that shops spend between $10,000 and $50,000 on a good entry-level machine. As for where to start when searching for a 3D printer, he suggests that shops do some research online and talk with salespeople to get an idea of which system is the best fit for their applications. Shops can also have service providers make some sample parts to get an idea of what they can produce.

Build relationships with service providers. Mr. Miller points out that shops do not have to purchase their own 3D printers in order to start familiarizing themselves with additive manufacturing. “You don’t necessarily have to bring it in house,” he says. “There are some really good experts out there.” Shops can find additive manufacturing service providers and start building relationships with them, so when customers do need those capabilities, shops know where to turn to provide them. This way, customers can get the experience of a one-stop shop. “It's no different than sending parts out for other operations such as grinding,” Mr. Miller says.

What to Watch

Mr. Miller also highlighted a couple of technological developments that could make additive manufacturing a more cost-effective solution for higher-volume production environments.

Higher-volume polymer systems. Mr. Miller predicts that within five years, several higher-volume, liquid and powder-based polymer 3D printers will hit the market. “Higher volume” for the additive manufacturing market means part volumes in the thousands. While they still will not be able to reach the volumes of high-production machining environments, they will make 3D printing a more cost-effective solution for producing parts. “Make sure you keep an eye on them because they’re going to lower the per-part cost,” Mr. Miller says. The technology for these systems is already out there, from companies including Evolve, HP and Carbon, but it is still in the early stages of development, and using it requires some expertise.

Low-cost metal systems. “We’re hoping low-cost metal AM will happen soon,” Mr. Miller says. According to him, promising solutions from companies including Desktop Metal and Markforged already exist, but they are still being tested and are not yet widely available. Cheaper metal AM systems will make it easier for shops to bring these processes in house.

RELATED CONTENT

-

3D Printing vs. CNC Milling for Prototyping

Many factors, such as price, part size and material come into play when deciding whether 3D printing or CNC milling is the best method for making a prototype.

-

Gift a 3D Printer to an Employee?

Some shops have purchased inexpensive polymer 3D printers for their operations. Does it make sense to take this a step further and give (or loan) a sharp young employee one to experiment with at home? This small investment could pay off for your shop in different ways.

-

Ceratizit Presents Team Cutting Tools and Turns Turning Upside Down

Luxembourg-based Ceratizit Group invited more than 50 journalists from 15 countries for their Open Days 2019 press event from May 13-15 to present the new Team Cutting Tools and its new turning technology High Dynamic Turning.